Preparation method of bi-physically-crosslinked self-repairing hydrogel

A physical cross-linking and hydrogel technology, applied in the field of functional polymer materials, can solve the problems of limited application and poor mechanical properties, and achieve the effects of low raw material cost, simple and easy preparation method, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put 0.79g of sodium dodecylbenzenesulfonate, 0.52g of octadecyl methacrylate and 5.48g of acrylamide in 20g of water, and stir at 35°C for 5h until dissolved to obtain a reaction precursor. Add 0.03 g of potassium persulfate to the precursor solution and stir for 30 minutes, then pour into a cylindrical mold, and react at 50°C for 12 hours to obtain a single-physically cross-linked hydrogel.

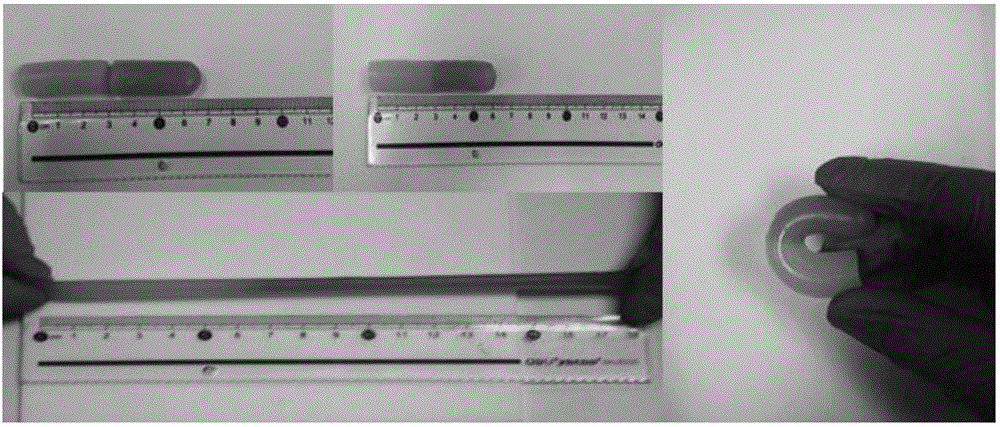

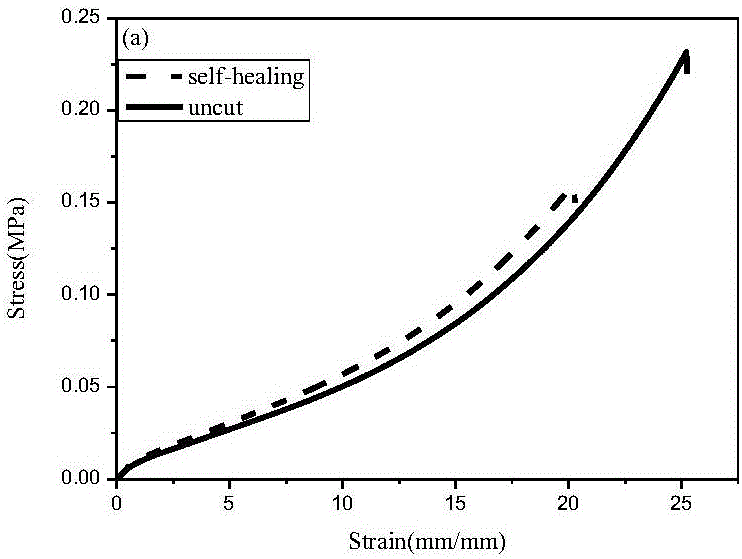

[0019] The self-repairing test is done to the sample obtained in this embodiment:

[0020] The prepared cylindrical gel was cut into two sections with a knife, and the cross-sections of the obtained two sections of gel were placed in a cylindrical mold, repaired at 60°C for 5 hours, and then the tensile strength before and after the repair was tested by a stretching machine. Compare and calculate its repair efficiency.

Embodiment 2

[0022] Disperse 0.18 g of sodium montmorillonite in 20 g of water, ultrasonicate for 3 hours, stir at room temperature for 12 hours, then add 5.48 g of acrylamide and stir at room temperature for 12 hours to obtain a montmorillonite-acrylamide aqueous solution. 0.79 g of sodium dodecylbenzenesulfonate and 0.52 g of octadecyl methacrylate were added to the above aqueous solution, and stirred at 35° C. for 5 h to obtain a reaction precursor. Then add 0.03 g of potassium persulfate to the precursor solution, and stir for 30 min, then pour into a cylindrical mold, and react at 50° C. for 12 h to obtain the double physically cross-linked self-healing hydrogel.

[0023] The self-repair test method for the sample obtained in this embodiment is the same as that in embodiment one.

Embodiment 3

[0025] Disperse 0.36g of sodium-based montmorillonite in 20g of water, ultrasonicate for 3 hours, stir at room temperature for 12 hours, then add 5.48g of acrylamide and stir at room temperature for 12 hours to obtain a montmorillonite-acrylamide aqueous solution. 0.79 g of sodium dodecylbenzenesulfonate and 0.52 g of octadecyl methacrylate were added to the above aqueous solution, and stirred at 35° C. for 5 h to obtain a reaction precursor. Then add 0.03 g of potassium persulfate to the precursor solution, and stir for 30 min, then pour into a cylindrical mold, and react at 50° C. for 12 h to obtain the double physically cross-linked self-healing hydrogel.

[0026] The preparation method of the double physically cross-linked self-healing hydrogel of this embodiment is the same as that of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com