Self-repairing film

A self-healing and self-selecting technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor wear resistance of plastic films, irreversible recovery or repair, etc., and achieve high scratch resistance, high hardness, Effects of low shrinkage stress deformation and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

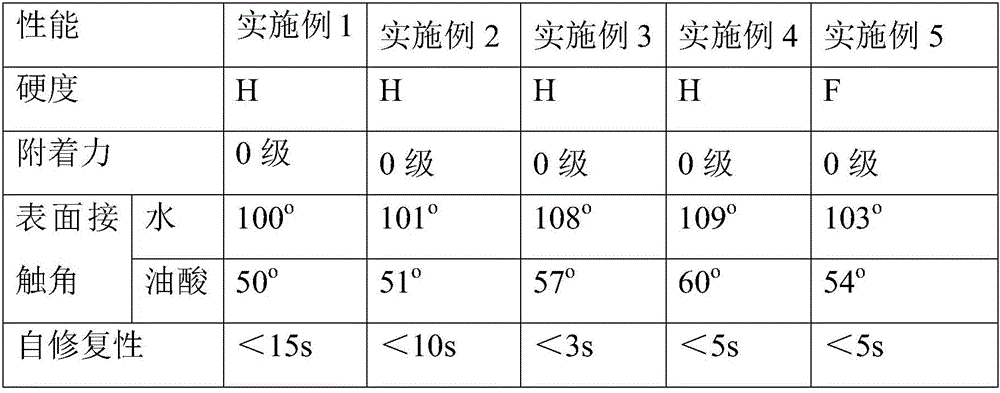

Examples

Embodiment 1

[0021] 100 parts of polycaprolactone trihydric alcohol (Daicel Chemical PLACCEL 308), 60 parts of trimer of hexamethylene diisocyanate, 4 parts of leveling agent BYK-370 (Byke Chemicals), 48 parts of ethyl acetate , 68 parts of butyl acetate and 48 parts of propylene glycol methyl ether acetate were stirred and mixed evenly at high speed. Before coating, add 0.15 parts of triethylenediamine and stir at high speed for 0.5h to mix well.

[0022] The transparent carrier layer was selected as a polyethylene terephthalate 100 μm base film (Yihua Toray Polyester Film Co., Ltd., PY-2Z), and the self-healing functional layer components were coated on the transparent substrate by slit coating. The carrier layer has a dry film thickness of 40 μm and is dried and cured for 3 minutes using a stepwise heating method of 70°C / 90°C / 130°C / 140°C / 110°C. After curing for 24 hours in a curing room at ℃, a self-healing film was obtained.

Embodiment 2

[0024] 100 parts of polyester polyol (Zhongshan Jieshida PU301), 80 parts of trimer of hexamethylene diisocyanate, 4 parts of leveling agent DSP637 (Zhongshan Jieshida), 54 parts of methyl ethyl ketone, 72 parts of butyl acetate Stir and mix evenly with 54 parts of propylene glycol methyl ether at high speed. Before coating, add 0.10 parts of tetramethylguanidine and stir at high speed for 0.5 h to mix well.

[0025] The transparent carrier layer is selected as a polycarbonate 125 μm base film (Saudi Basic Industries Corporation), and the self-healing functional layer components are coated on the transparent carrier layer by a slit coating method so that the dry film thickness is 50 μm and the temperature is raised in steps at 70°C / 90°C / 130°C / 140°C / 110°C was dried and cured for 3 minutes, then the self-healing functional layer was coated with a fluorine release film and rolled up, and finally placed in a 50°C curing room and cured for 24 hours to obtain a self-healing film. ...

Embodiment 3

[0027] Mix 100 parts of acrylic polyol (Asia Industry TRE-2-S2), 42 parts of isocyanate-containing oligomer X-06 (Asia Industry), 2 parts of leveling agent BYK-371, 33 parts of ethyl acetate, 16 parts Butyl acetate and 33 parts of propylene glycol methyl ether were stirred and mixed evenly at high speed. Before coating, add 0.07 part of potassium isooctanoate and stir for 0.5 h to mix well.

[0028] The transparent carrier layer was selected as a polyethylene terephthalate 125 μm base film (Yihua Toray Polyester Film Co., Ltd., PY-2Z), and the self-healing functional layer components were coated on the transparent substrate by slit coating. The carrier layer has a dry film thickness of 25 μm and is dried and cured for 3 minutes using a stepwise heating method of 70°C / 90°C / 130°C / 130°C / 110°C. After curing for 24 hours in a curing room at ℃, a self-healing film was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com