Compound crosslinking agent, preparation method of compound crosslinking agent and preparation method of profile control agent

A composite cross-linking agent and catalyst technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high volatility and toxicity, short gelation time, easy syneresis, etc., and achieve deep profile control and oil displacement effect, wide temperature adaptability, and gel system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

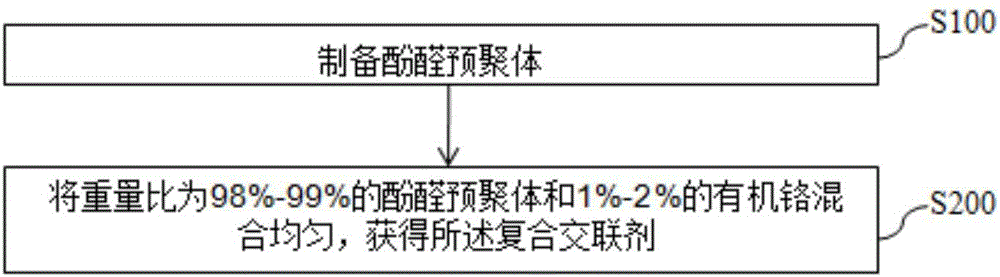

[0036] On the other hand, based on the same inventive concept, the embodiment of the present invention provides a preparation method of the above-mentioned composite crosslinking agent, please refer to figure 1 ,include:

[0037] Step S100: preparing a phenolic prepolymer;

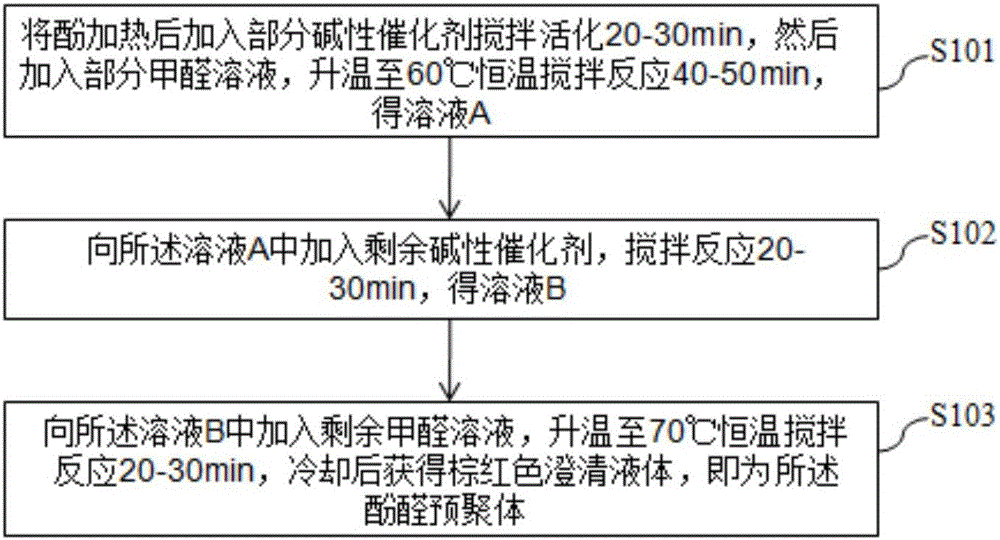

[0038] Please refer to figure 2 , this step includes the following sub-steps:

[0039] Step S101: After heating the phenol, add part of the basic catalyst and stir for activation for 20-30 minutes, then add part of the formaldehyde solution, raise the temperature to 60°C and stir for 40-50 minutes at a constant temperature to obtain solution A;

[0040] Described phenol is any one in phenol, resorcinol, hydroquinone. Wherein the heating temperature is controlled between 40°C-60°C, preferably 50°C. Since the melting point of phenol is 40°C, phenol can become molten at this temperature. Because the reaction to generate phenolic prepolymer is an exothermic reaction, if the heating temperature of phenol ...

Embodiment 1

[0058] Put the three-necked flask equipped with a stirrer and a condenser in an electric heating constant temperature water bath, add 33.5g of phenol, adjust the temperature to 50°C, and melt the phenol into a liquid; add 1.6g of sodium hydroxide, and stir for 20min; add formaldehyde solution ( 40%) 43.2g, heated up to 60°C, kept for 50min; added 0.8g of sodium hydroxide again, stabilized for 20min; added 23.3g of formaldehyde solution (40%), heated up to 70°C, and reacted for 30min; cooled to obtain phenolic prepolymer .

[0059] Take 99.0 g of phenolic prepolymer, add 1.0 g of chromium acetate, and mix evenly to obtain a composite crosslinking agent.

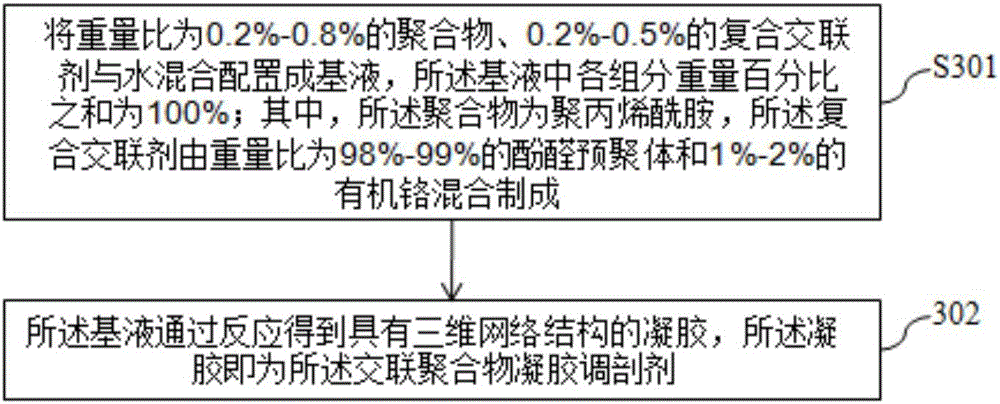

[0060] Prepare a partially hydrolyzed polyacrylamide solution with a mass fraction of 0.2%, and after aging for 24 hours, add a composite cross-linking agent to make the mass fraction 0.2%, and react at a constant temperature of 50°C for 3 days to generate a cross-linked polymer gel profile control agent. The glue viscosity i...

Embodiment 2

[0063] Put the three-neck flask equipped with a stirrer and a condenser in an electric heating constant temperature water bath, add 33.5g of phenol, adjust the temperature to 50°C, and melt the phenol into a liquid; add 1.5g of sodium hydroxide, and stir for 30min; add formaldehyde solution ( 40%) 46.5g, heated up to 60°C, kept for 50min; added 0.9g of sodium hydroxide again, stabilized for 30min; added 20.0g of formaldehyde solution (40%), heated up to 70°C, and reacted for 30min; cooled to obtain phenolic prepolymer .

[0064] Take 99.0 g of phenolic prepolymer, add 1.0 g of chromium citrate, and mix evenly to obtain a composite crosslinking agent.

[0065] Prepare a partially hydrolyzed polyacrylamide solution with a mass fraction of 0.3%. After aging for 24 hours, add a composite cross-linking agent to make the mass fraction 0.2%, and react at a constant temperature of 65°C for 1 day to generate a cross-linked polymer gel profile control agent. The glue viscosity is 14916...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com