Method for separating and extracting essential oil from ocimum gratissimum

A technology of clove basil and extraction method, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat generation, etc., can solve the problems of shortening extraction time, long extraction time, low extraction efficiency, etc., and achieves simple and easy operation, high extraction High efficiency and full extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

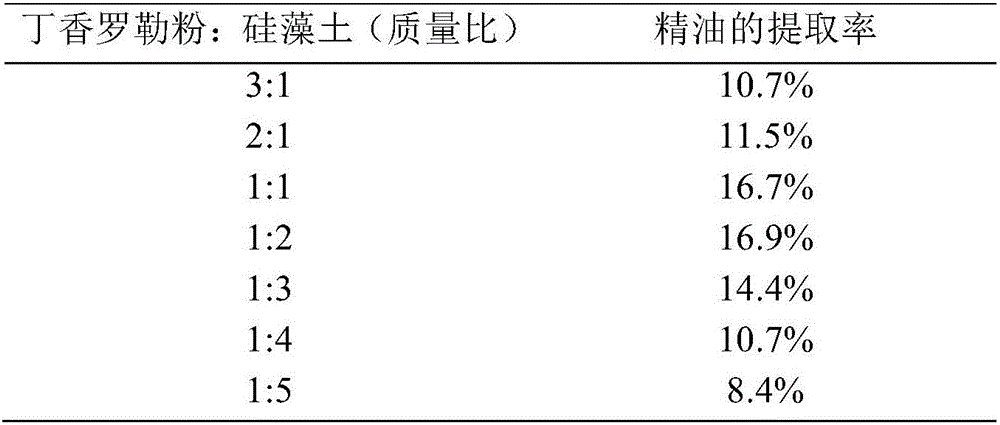

[0020] (1) Take the aerial part of the clove basil plant, wash it with clear water, dry it at room temperature, pulverize it and mix it with diatomaceous earth in a mass ratio of 1:1, and grind it evenly to obtain a mixed sample;

[0021] (2) Add 2 times the amount of chloroform to the mixed sample in step (1), place it in an ultrasonic instrument for extraction, the extraction temperature is 40° C., and the extraction time is 30 minutes, and filter to obtain the filtrate and residue;

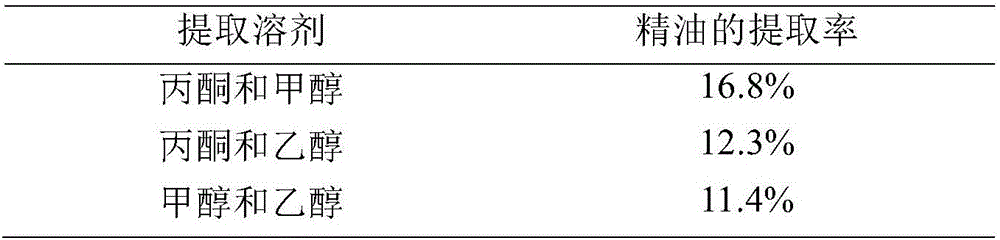

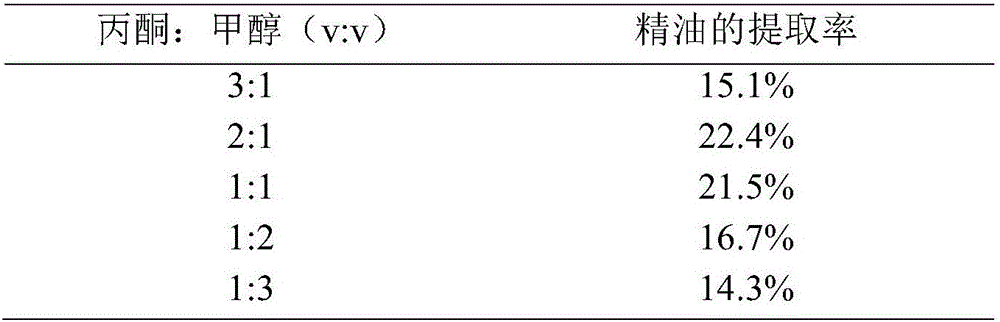

[0022] (3) Transfer the residue of step (2) to the extraction tank with filter paper at the bottom, and fill the extraction tank with the residue, perform accelerated solvent extraction to obtain the extract, and filter to obtain the filtrate; wherein, set the accelerated The parameters of solvent extraction are: extraction solvent: a mixture of acetone and methanol with a volume ratio of 2:1, extraction temperature 60°C, extraction pressure 1000psi, extraction times 3 times, extraction time 5mi...

Embodiment 2

[0026] (1) Take the above-ground part of the clove basil plant, wash it with water, dry it at room temperature, pulverize it and mix it with diatomaceous earth in a mass ratio of 1:3, and grind it evenly to obtain a mixed sample;

[0027] (2) Add 4 times the amount of chloroform to the mixed sample in step (1), place it in an ultrasonic instrument for extraction, the extraction temperature is 50° C., and the extraction time is 50 minutes, and filter to obtain the filtrate and residue;

[0028] (3) Transfer the residue of step (2) to the extraction tank with filter paper at the bottom, and fill the extraction tank with the residue, perform accelerated solvent extraction to obtain the extract, and filter to obtain the filtrate; wherein, set the accelerated The parameters of solvent extraction are: extraction solvent: a mixture of acetone and methanol with a volume ratio of 1:1, extraction temperature 150°C, extraction pressure 3000psi, extraction times 5 times, extraction time 30...

Embodiment 3

[0032] (1) Take the above-ground part of the clove basil plant, wash it with water, dry it at room temperature, pulverize it and mix it with diatomaceous earth in a mass ratio of 1:2, and grind it evenly to obtain a mixed sample;

[0033] (2) Add 3 times the amount of chloroform to the mixed sample in step (1), place it in an ultrasonic instrument for extraction, the extraction temperature is 45 ° C, the extraction time is 40 min, and filter to obtain the filtrate and residue;

[0034] (3) Transfer the residue of step (2) to the extraction tank with filter paper at the bottom, and fill the extraction tank with the residue, perform accelerated solvent extraction to obtain the extract, and filter to obtain the filtrate; wherein, set the accelerated The parameters of solvent extraction are: extraction solvent: a mixture of acetone and methanol with a volume ratio of 2:1, extraction temperature 100°C, extraction pressure 2000psi, extraction times 4 times, extraction time 20min, pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com