Self-insulation wallboard poured with polyurethane sandwich layer and manufacturing and forming method of self-insulation wallboard

A technology of self-insulation and polyurethane, which is applied in the direction of building structure, building components, construction, etc., can solve the problems of foam brittleness, high viscosity of the system, and large thermal conductivity, and achieve high temperature resistance, flame retardancy, and The effect of excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

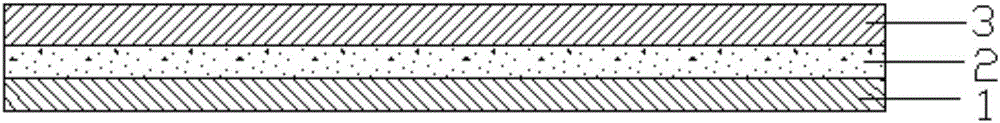

[0050] Cast polyurethane sandwich self-insulation wallboard, including inner cement board 1 and outer cement board 3, between the inner cement board 1 and outer cement board 3 is a polyurethane hard foam insulation sandwich layer 2, and the polyurethane hard foam insulation sandwich The core layer 2 is formed by pouring inorganic hybrid melamine polyurethane rigid foam material;

[0051] Inorganic hybrid melamine polyurethane rigid foam material is made of inorganic hybrid melamine polyurethane combined with polyether and polymerized isocyanate foaming;

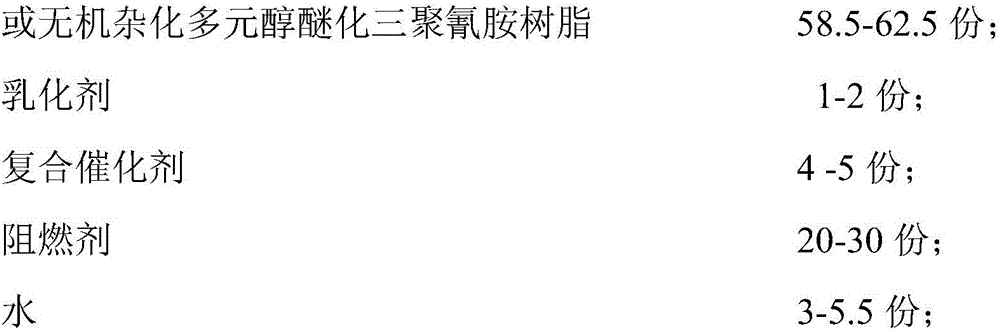

[0052] Inorganic hybrid melamine polyurethane combination polyether, according to the ratio of parts by weight, the formula is as follows:

[0053]

[0054]

[0055] The thickness of the polyurethane rigid foam insulation sandwich layer is 0.5cm.

[0056] The combination of the rigid polyurethane foam insulation sandwich layer 2 with the inner cement board 1 and the outer cement board 3 is directly cured and bonded, an...

Embodiment 2

[0083] Cast polyurethane sandwich self-insulation wallboard, including inner cement board 1 and outer cement board 3, between the inner cement board 1 and outer cement board 3 is a polyurethane hard foam insulation sandwich layer 2, and the polyurethane hard foam insulation sandwich The core layer 2 is formed by pouring inorganic hybrid melamine polyurethane rigid foam material;

[0084] Inorganic hybrid melamine polyurethane rigid foam material is made of inorganic hybrid melamine polyurethane combined with polyether and polymerized isocyanate foaming;

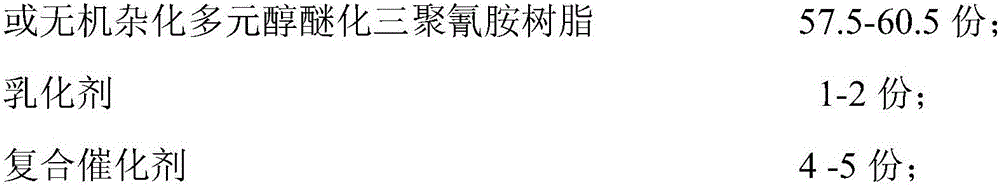

[0085] Inorganic hybrid melamine polyurethane combination polyether, according to the ratio of parts by weight, the formula is as follows:

[0086]

[0087] The polyurethane rigid foam insulation sandwich layer (2) has a thickness of 8 cm.

[0088] The combination of the rigid polyurethane foam insulation sandwich layer (2) with the inner cement board (1) and the outer cement board (3) is directly cured and bonded, and th...

Embodiment 3

[0116] Cast polyurethane sandwich self-insulation wallboard, including inner cement board 1 and outer cement board 3, characterized in that: between the inner cement board 1 and outer cement board 3 is a polyurethane hard foam insulation sandwich layer 2, and the polyurethane The rigid foam insulation sandwich layer 2 is formed by pouring inorganic hybrid melamine polyurethane rigid foam material;

[0117] Inorganic hybrid melamine polyurethane rigid foam material is made of inorganic hybrid melamine polyurethane combined with polyether and polymerized isocyanate foaming;

[0118] Described inorganic hybrid melamine polyurethane combination polyether, by weight ratio, formula is as follows:

[0119]

[0120]

[0121] The thickness of polyurethane rigid foam insulation sandwich layer 2 is 12cm.

[0122]The combination of the rigid polyurethane foam insulation sandwich layer 2 with the inner cement board 1 and the outer cement board 3 is directly cured and bonded, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com