Hot melting connecting structure between metal-plastic composite pipes and manufacturing method of hot melting connecting structure

A metal-plastic, connection structure technology, applied in the direction of pipeline connection layout, pipe/pipe joint/pipe fitting, pipe support, etc., can solve the problems of pipe fusion joint diameter reduction, pipe material connection piece and connection method construction difficulty, etc., to achieve joint strength Large, reduce manual drawbacks, and the effect of high connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

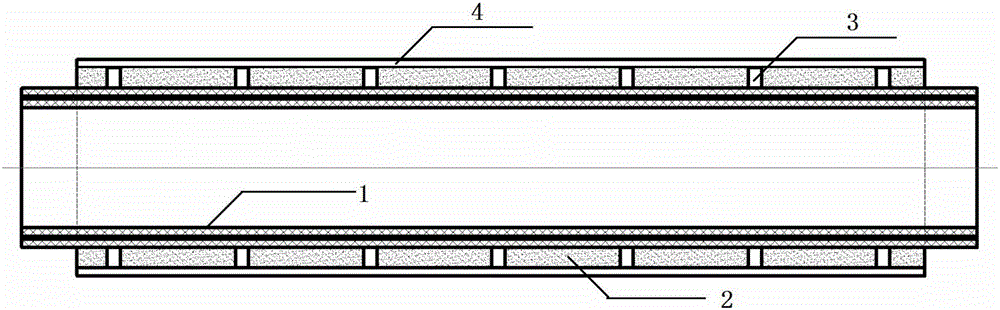

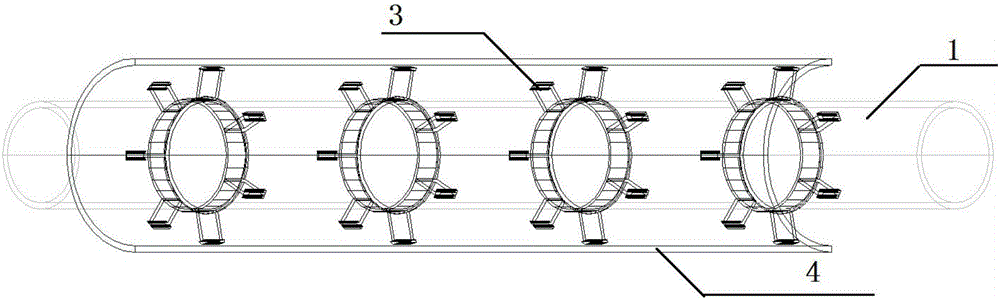

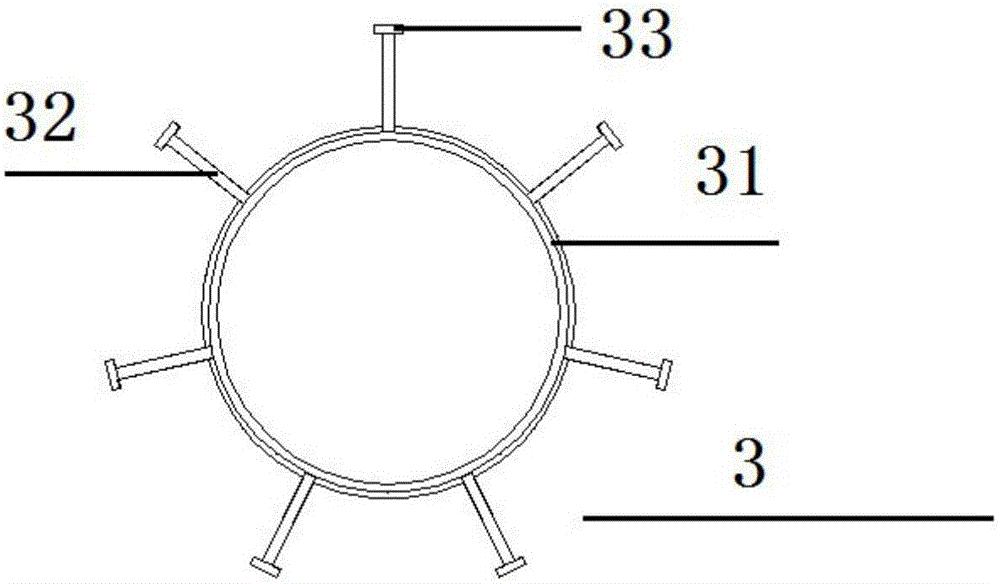

[0038] Combine below Figure 1 to Figure 5 , the present invention is further described:

[0039] Such as figure 1 As shown, a metal-plastic composite pipe includes a metal composite pressure pipe fitting 1, the outer layer of the metal composite pressure pipe fitting 1 is provided with a rigid polyurethane foam insulation layer 2, and the exterior of the rigid polyurethane foam insulation layer 2 is provided with a high-density polyethylene waterproof Anti-corrosion layer 4.

[0040] The invention replaces the original steel work pipe or plastic work pipe heat preservation structure type, and is a new type of green environmental protection pipe that integrates the advantages of steel work pipe and plastic work pipe, and is more suitable for systems such as central heating, direct hot water supply pipelines for geothermal wells, etc. , at 95°C, the long-term use pressure can reach 1.25MPa, making contributions to reducing environmental pollution, reducing heat consumption, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com