Waste heat recovery system for biomass compression forming device

A waste heat recovery system and compression molding technology, used in heating devices, drying gas layout, lighting and heating equipment, etc., can solve the problem of high water content, reduce processes, save production costs, and speed up evaporation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

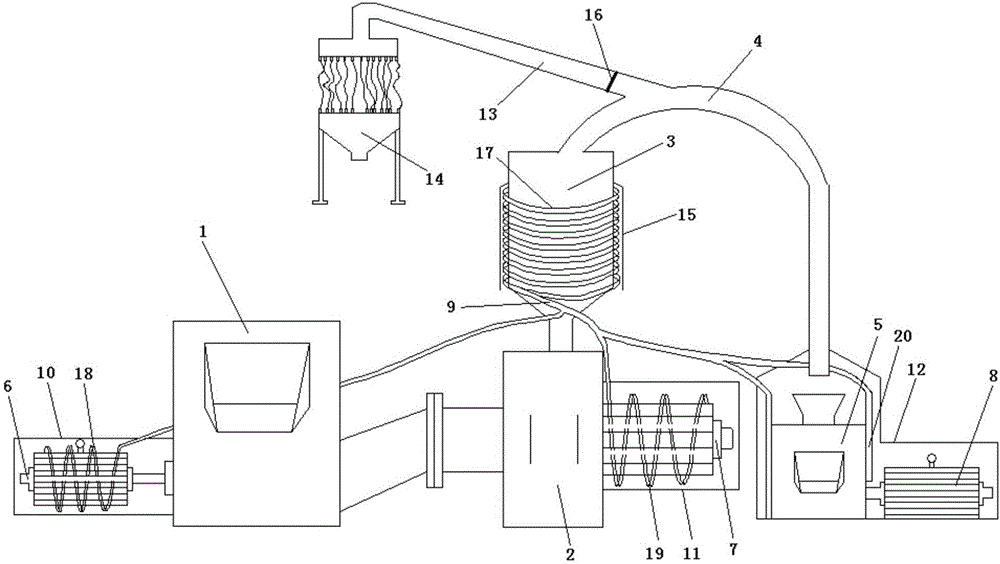

[0013] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0014] Such as figure 1 As shown in the figure, the biomass compression molding device waste heat recovery system according to the present invention includes a pulverizer 1, a fan 2, a buffer bin 3, a blowing and washing pipeline 4, a pelletizer 5, an A-type drive motor 6, and a B-type drive motor 7 , C-type drive motor 8, normal temperature heat pipe 9, A-type sealed heat-insulation cover 10, B-type sealed heat-insulation cover 11 and heat-insulation cover 12,

[0015] The normal temperature heat pipe 9 includes a condensation section 17, a first evaporation section 18, a second evaporation section 19, and a third evaporation section 20;

[0016] The A-type drive motor 6 and the A-type sealed insulation cover 10 are installed on the pulverizer 1 on the left side of the pulverizer 1, and the A-type drive motor 6 is located in the A-type sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com