Combustion detection system and combustion detection method thereof

A detection system and optical detection technology, applied in measurement devices, heat measurement, instruments, etc., can solve a lot of problems such as time adjustment, laser deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

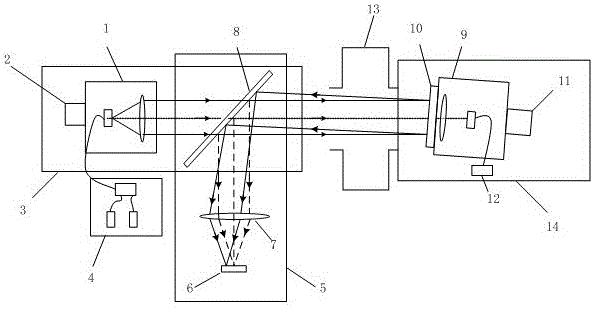

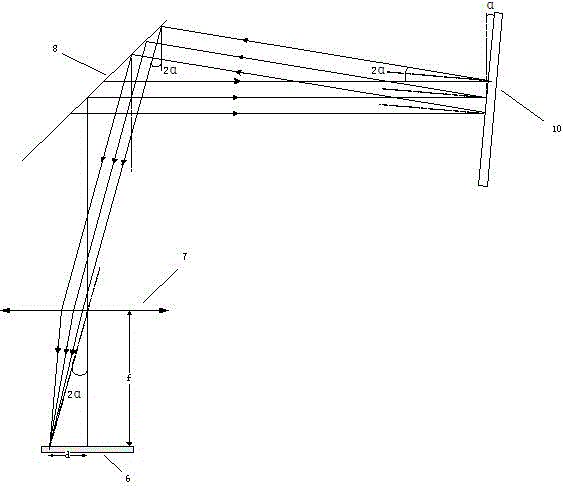

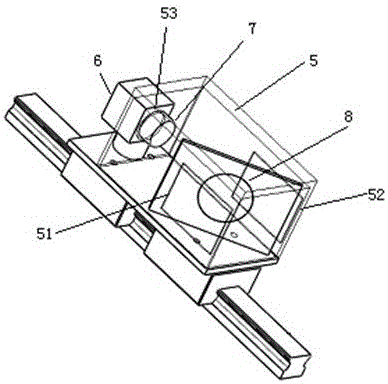

[0025] The combustion detection system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the combustion detection system of the present invention can quickly align and measure the deformation of the furnace wall under cold machine conditions. Ⅰ3. Laser switching device 4, optical path calibration device, receiving device 9, optical filter 10, turntable II11, photoelectric detector 12, mechanical cantilever II14. The boiler temperature field 13 is located in the boiler furnace. Turntable I and turntable II are orthogonal rotary turntables that rotate orthogonally in the horizontal and vertical directions, and can be manually adjusted or controlled by the turntable.

[0027] The emission end of the combustion detection system is composed of the emission device 1, the turntable I2, the mechanical cantilever I3, the laser switching device 4, and the optical path calibration device. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com