A device and method for measuring carbon dioxide content in pyrite

A technology of carbon dioxide and pyrite, which is applied to the analysis of materials and instruments, can solve the problems of measurement result deviation and data deviation, and achieve the effect of small footprint, large measurement range and less time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

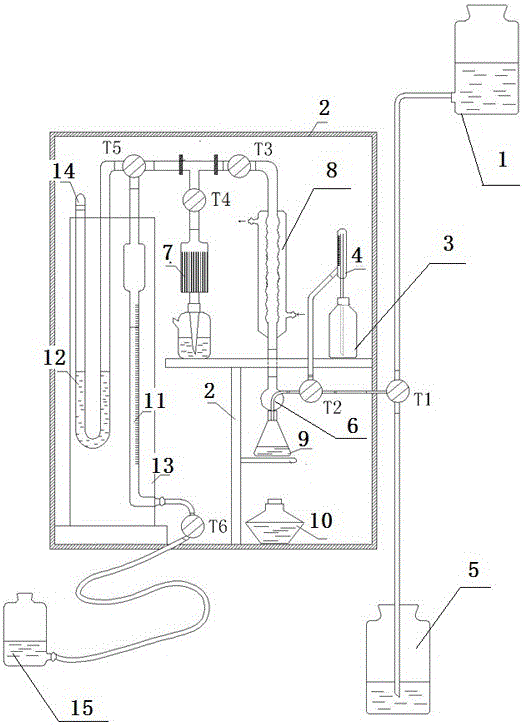

[0038] Embodiment 1, with reference to figure 1 , a device for measuring carbon dioxide content in pyrite,

[0039] The device comprises a support 2 on which a plastic bottle 3 and a capillary absorber 7 are arranged;

[0040] The plastic bottle 3 is provided with an acid-adding casing 4 connected by a rubber stopper. The acid-adding casing 4 is composed of a glass outer tube and an inner tube. At the bottom, there is an air outlet on the upper part of the glass outer tube;

[0041]The bracket 2 below the plastic bottle 3 is provided with a decomposing bottle 9, an alcohol lamp 10 is arranged below the decomposing bottle 9, and a ground sleeve 6 is connected on the decomposition bottle 9, and the ground sleeve 6 includes an external sleeve, and the external sleeve There is an internal casing inside the tube, the lower end of the internal casing communicates with the decomposition bottle 9, and the upper end extends out of the external casing to connect with the three-way coc...

Embodiment 2

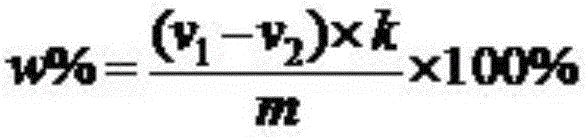

[0043] Embodiment 2, a method for measuring carbon dioxide content in pyrite, the method uses the device for measuring carbon dioxide content in pyrite described in embodiment 1, the method may further comprise the steps:

[0044] (1) Preparatory work: Before measuring, it is necessary to remove the carbon dioxide in the cooling jacket tube 8 to the gas measuring tube 11, and adjust the barometer liquid level of the U-shaped compensating tube to the level, and simultaneously remove the potassium hydroxide liquid in the capillary absorber 7. When the surface is adjusted to the upper scale, the liquid level of the solution in the gas measuring tube 11 rises to the top, and its position is determined according to the work requirements at that time; through the positive and negative pressure inspection brought by the balance bottle 15 lifting, it is proved that there is no air leakage, that is, It can be prepared for sample measurement; add 1% dilute sulfuric acid for exhaust in th...

Embodiment 3

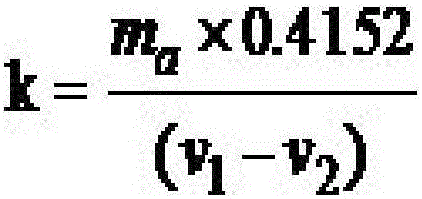

[0062] Embodiment 3, the method experiment one of measuring carbon dioxide content in pyrite:

[0063] 1. Preparation of reagents

[0064] The water used in this example complies with the specifications of third-grade water in GB / T6 682; the listed reagents, unless otherwise specified, refer to analytically pure reagents.

[0065] 1.1 Benchmark sodium carbonate: burn to constant weight at 300°C before weighing;

[0066] 1.2 Add 3% copper sulfate to phosphoric acid solution: weigh 15g CuSO 4 ·5H 2 O solid, add to the prepared 1+1 phosphoric acid solution, dissolve and mix;

[0067] 1.3 Potassium hydroxide solution: 400g / L;

[0068] 1.4 Dilute sulfuric acid blocking solution: Add 1mL of sulfuric acid to 1000mL of water, add a few drops of 1g / L methyl orange indicator solution to make the solution red, and shake well;

[0069] 1.5 Dilute sulfuric acid exhaust solution: add 10mL sulfuric acid to 1000mL water, add a few drops of 1g / L methyl orange indicator solution to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com