Novel ionic liquid based complex structural well seepage electric simulation system

A complex structure, ionic liquid technology, applied in the field of oil and gas seepage, electrical simulation system, can solve the problems of large contact area between copper mesh electrode and electrolyte solution, poor current and voltage measurement accuracy, and unstable simulated electric field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

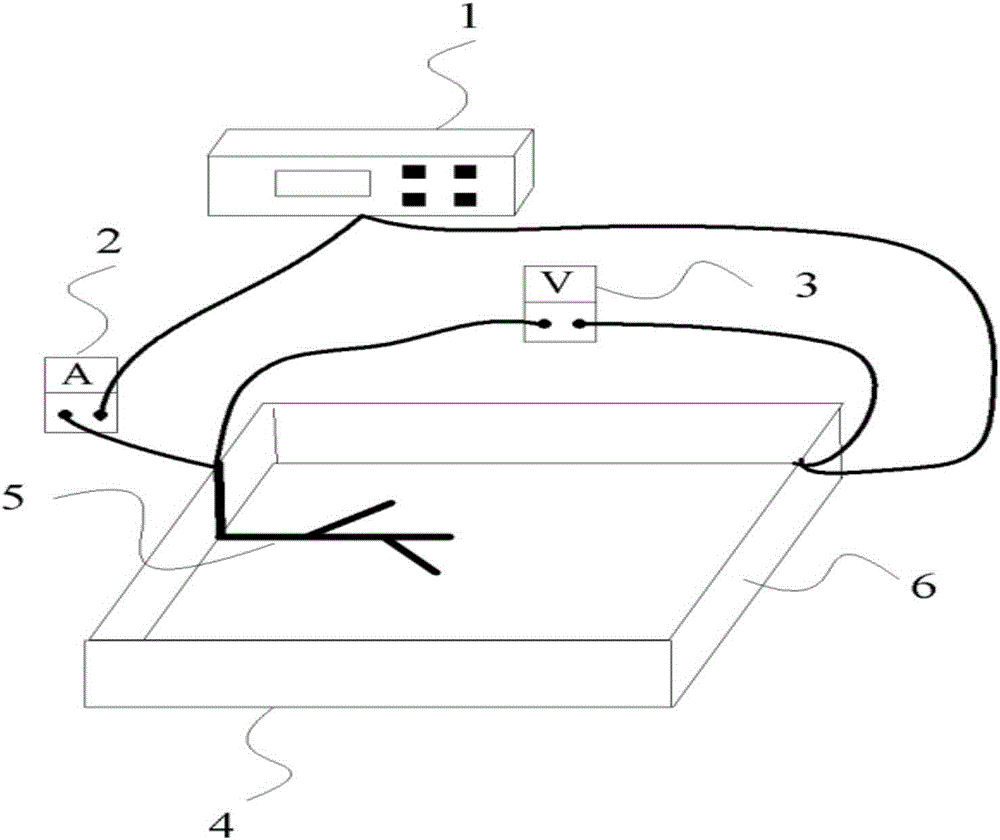

[0061] like Figure 4 As shown, it is a schematic structural diagram of the electrical simulation system for the seepage law of complex structured wells provided by the implementation of the present invention. The electrical simulation system includes: terminal control computer 201 , position sensor 202 , electrolyte tank 203 , copper rod probe 204 , simulated complex structure well 205 , voltmeter 206 , ammeter 207 , and voltage-regulating DC power supply 208 . The conductivity of the ionic liquid has the best compatibility with the metal copper electrode, so the metal copper is used as the material of the probe and the simulated well.

[0062] The working process of the device of the present invention: during normal operation, the electrolyte tank is placed on the workbench, the complex structure well model is placed in the electrolyte tank, the wire is connected to the probe of the data acquisition instrument, and the other wire is connected to the simulated complex structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com