Silicon carbide composite cladding failure evaluation model under reactor accident condition

A technology for accident condition and failure assessment, applied in design optimization/simulation, special data processing application, chemical process analysis/design, etc., can solve problems such as result error, ensure safety, exacerbate instability, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

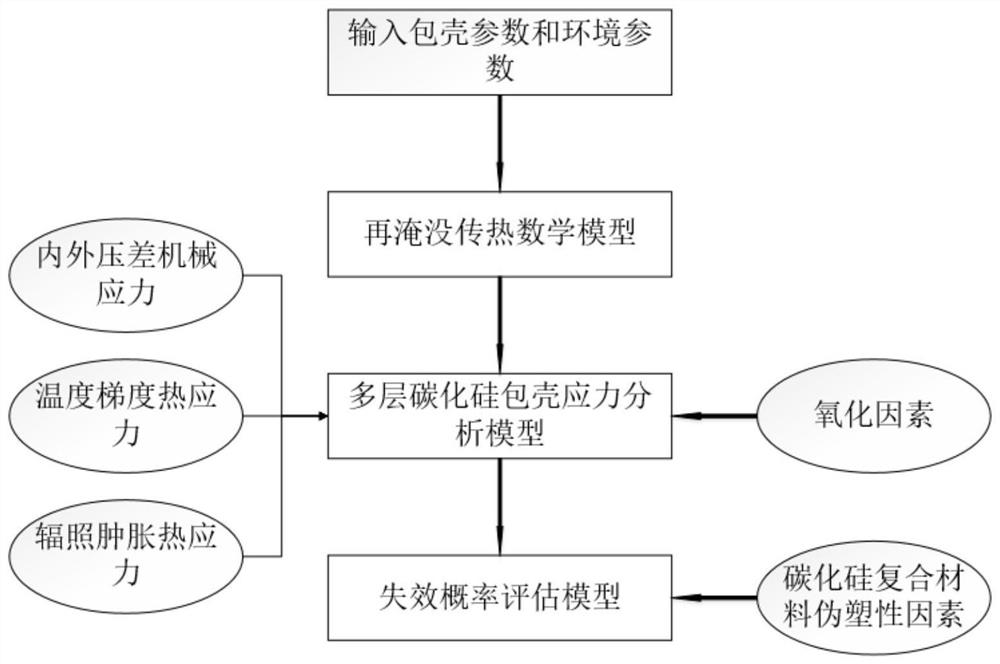

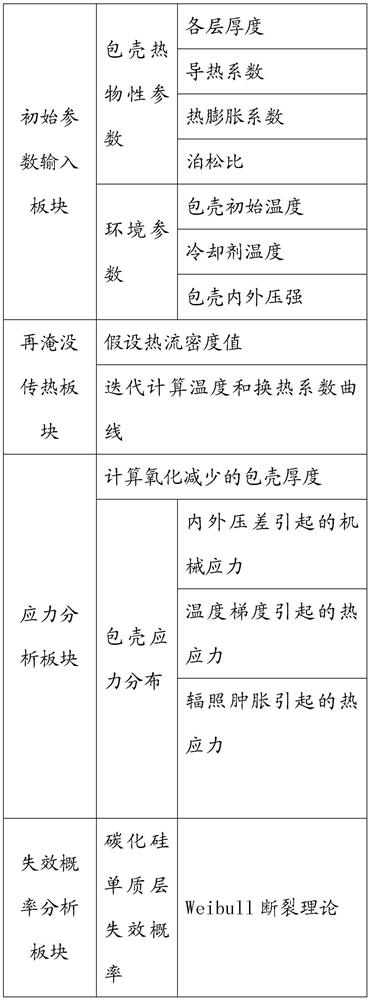

[0060] The present invention provides a silicon carbide composite cladding failure evaluation model under reactor accident conditions. The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

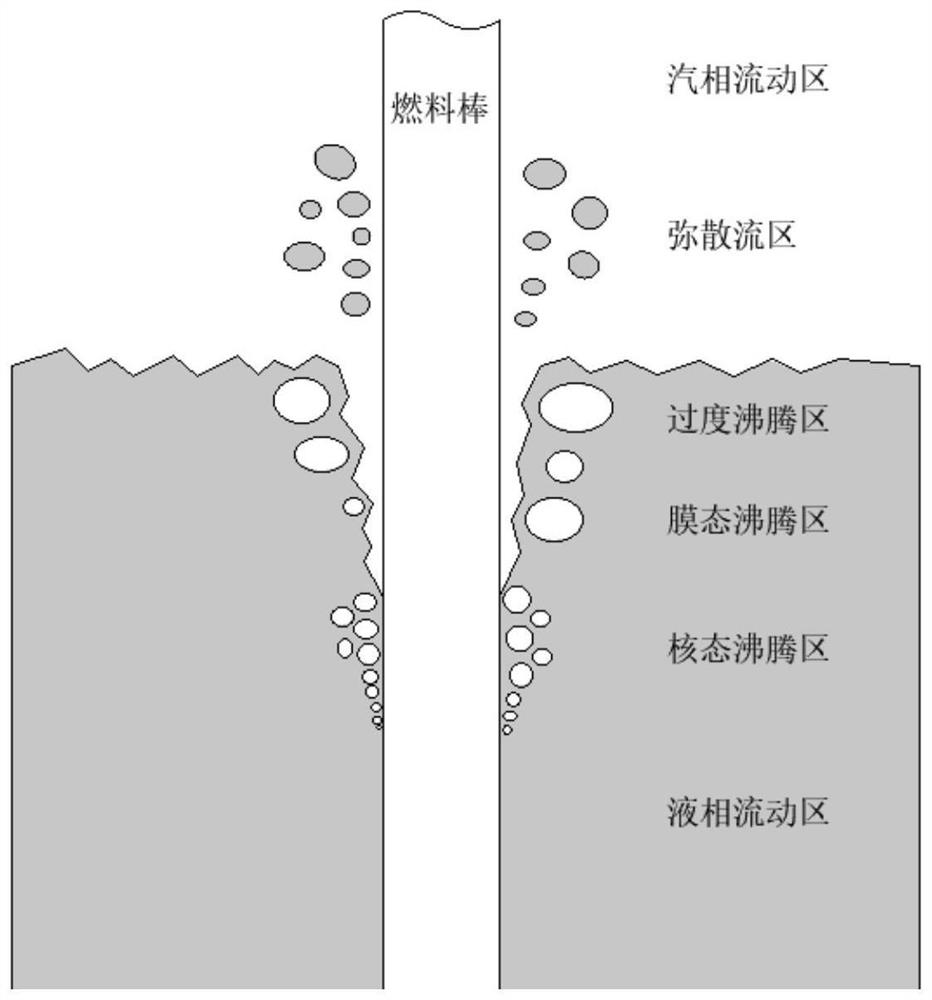

[0061] Internationally, the calculation and testing of the failure probability of the silicon carbide cladding is usually carried out under normal working conditions, so as to evaluate the silicon carbide material. But in fact, when an accident occurs and the core is in the reflooding stage, complex heat transfer phenomena will occur between the cooling water and the cladding, resulting in a change in the heat transfer coefficient. Therefore, the practice of setting the heat transfer coefficient to a constant value usually simplifies the model but produces a large error to the final result;

[0062] The present invention analyzes the heat transfer behavior between the multi-layer silicon carbide composite mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com