Ultrasonic detection device and method for multi-layered composite interface of metal pipe fitting

A technology for metal pipe fittings and ultrasonic testing, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problem of 100% coverage scanning of the pipe fitting interface. Correspondingly, the consistency of the mechanical control system at the probe end cannot be guaranteed, and it is difficult to achieve 100% liquid immersion coupling for long tubes, etc., to achieve good coupling effects, convenient disassembly and assembly, and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

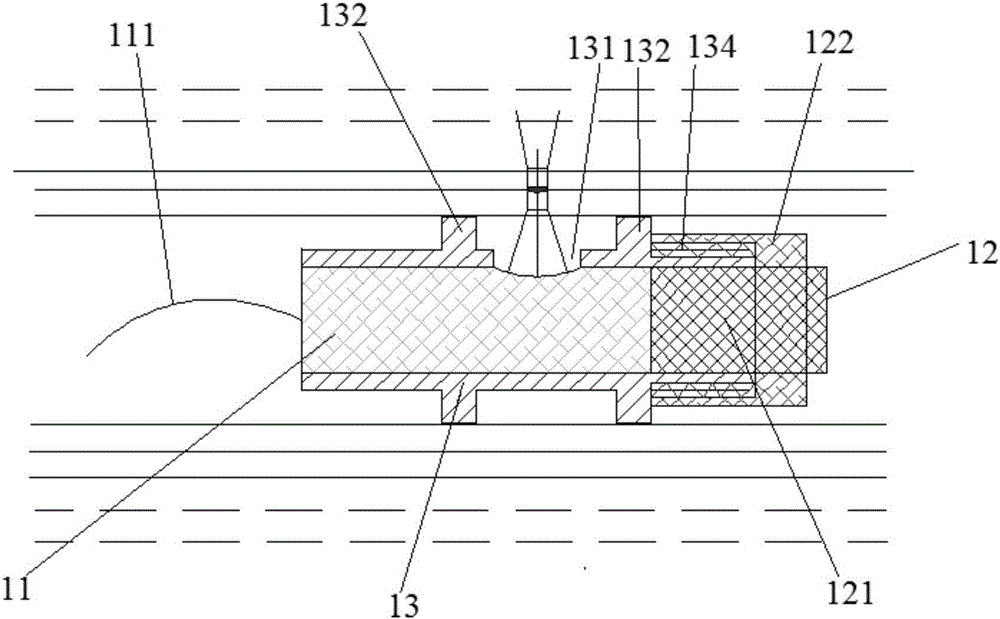

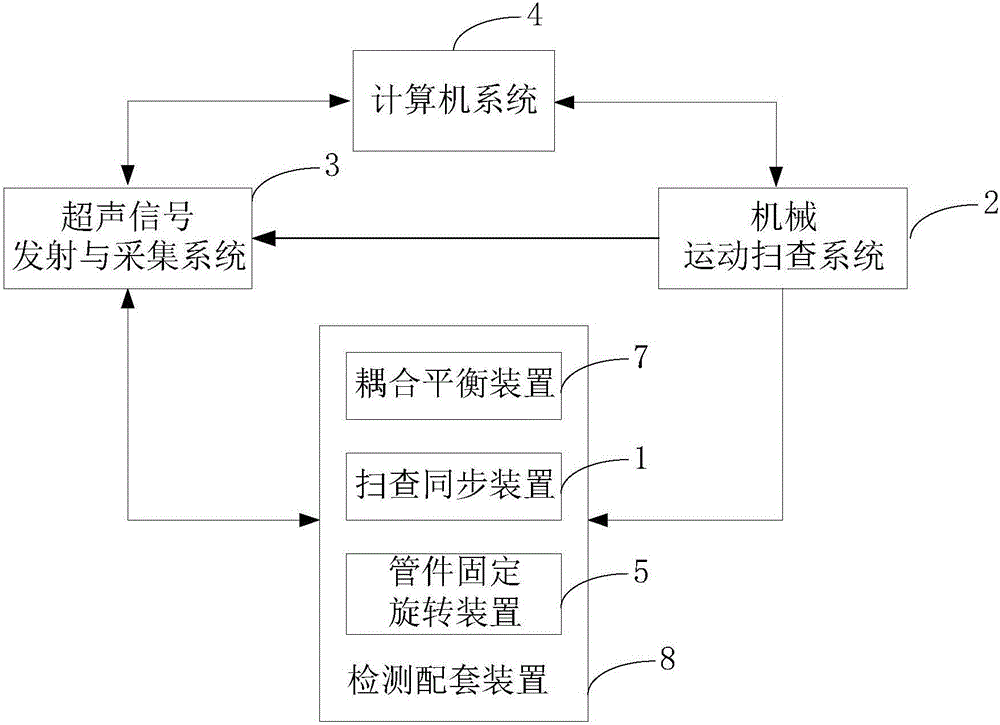

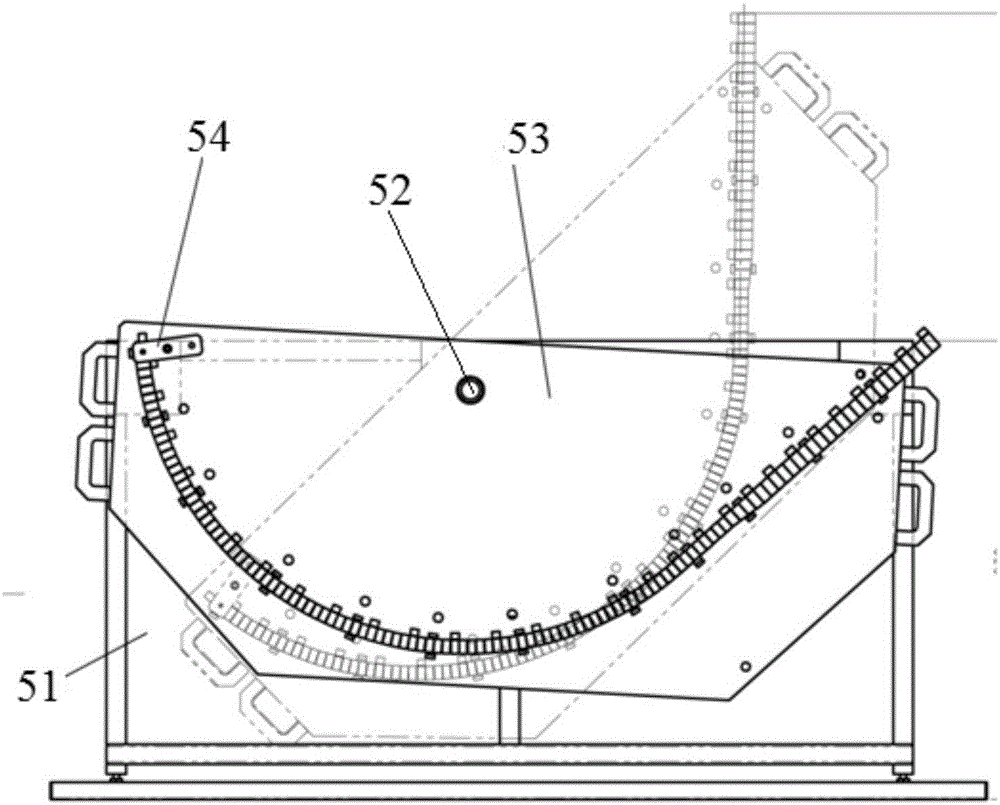

[0037] see Figure 1-12 , the embodiment of the present invention provides an ultrasonic detection device for the multi-layer composite interface of metal pipe fittings, which includes: a mechanical motion scanning system 2, a scanning synchronization device 1, an ultrasonic signal transmitting and collecting system 3, a computer system 4, a coupling balance The device 7 and the tube fix the rotating device 5 . For ease of description, the scanning synchronization device 1 , the coupling balance device 7 and the pipe fitting fixing and rotating device 5 may be collectively referred to as the detection matching device 8 . The metal pipe fitting 6 applicable to the ultrasonic testing device provided in this embodiment is a metal pipe fitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com