Rapid production method of paper-based microfluidic chip

A technology of a microfluidic chip and a manufacturing method, which is applied in the directions of analyzing materials and instruments, can solve the problems of easy clogging of the pen tip, affecting the detection, discontinuous hydrophobic boundary of the chip, etc., and achieves a fast and simple manufacturing process, cost reduction, and easy availability of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Fabrication of paper-based microfluidic chips:

[0034] (1) Take an ordinary writing water pen and use a syringe to absorb the ink in the refill.

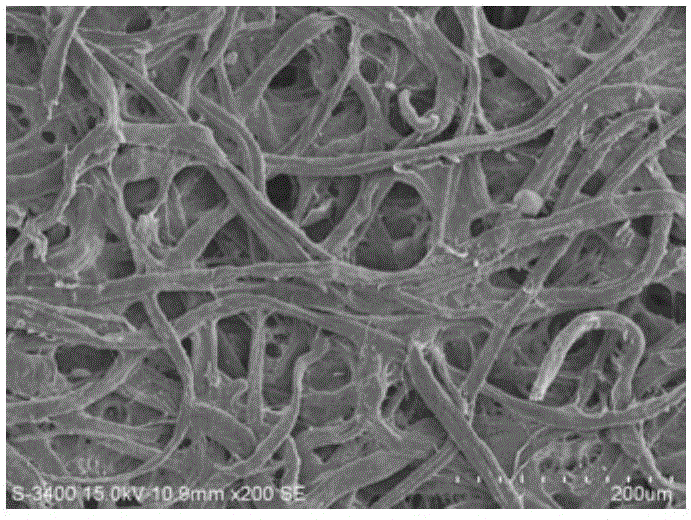

[0035] (2) Take 0.15g of vacuum silicone grease and add it to 12.5mL n-heptane, ultrasonically dissolve the vacuum silicone grease, then add 0.5g of alkyl ketene dimer (AKD) to the above solution, ultrasonically dissolve, and dissolve the The mixture is used as hydrophobic agent. Use a syringe to draw 0.1 mL of the above hydrophobic agent solution and inject it into a modified pen.

[0036] (3) Use the modified pen above to make a mold with an orifice plate with a diameter of 8mm, draw the pattern directly on Whatman#1 filter paper, then put it in an oven, and dry it at 100°C for 3 minutes to make a paper-based microfluidic chip Successfully, the properties of this chip are characterized by Figure 1a , 1b and Figure 2a , as shown in 2b.

Embodiment 2

[0038] Fabrication of paper-based microfluidic chips:

[0039] (1) Take an ordinary writing water pen and use a syringe to absorb the ink in the refill.

[0040] (2) Add 0.15g of vacuum silicone grease to 12.5mL of n-hexane, ultrasonically dissolve the vacuum silicone grease, then add 0.5g of paraffin wax to the above solution, ultrasonically dissolve, and use this mixture as a hydrophobic agent. Draw 0.1 mL with a syringe and inject into a modified fountain pen.

[0041] (3) Use the above-mentioned modified pen to draw patterns directly on the paper, and then dry it with a hot blower until the solvent is completely evaporated, and the paper-based microfluidic chip is successfully fabricated.

Embodiment 3

[0043] Paper-based microfluidic chip for the detection of uric acid samples:

[0044] (1) Take uric acid detection reagents uric acid oxidase (80U / mL), horseradish peroxidase (340U / mL), 4-aminoantipyrine (4mM / L), 3,5-dichloro-2- 1 μL of sodium hydroxybenzenesulfonate (8 mM / L) was sequentially added dropwise to the center of the detection area, and dried.

[0045] (2) Add uric acid standard solutions with concentrations of 0, 15, 35, 50, 75, and 100 ppm respectively and the processed serum samples S1 and S2 dropwise to the central positions of different detection areas, and dry.

[0046] (3) Use a mobile phone to take pictures of the detection area of the paper chip. The photos are as follows: image 3 As shown, and the photo is processed with ImageJ software to obtain the gray value, the gray value is the ordinate, and the concentration of each solution is the abscissa to make a standard curve, such as Figure 4 shown. Substituting the gray value of the measured sample, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com