Wafer level packaging based MEMS wind speed and wind direction sensor structure and packaging method

A wafer-level packaging, wind speed and direction technology, used in instruments, measurement devices, and the use of thermal variables to measure fluid velocity, etc., can solve problems such as affecting sensor performance, affecting sensor sensitivity and response time, and reducing power consumption and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

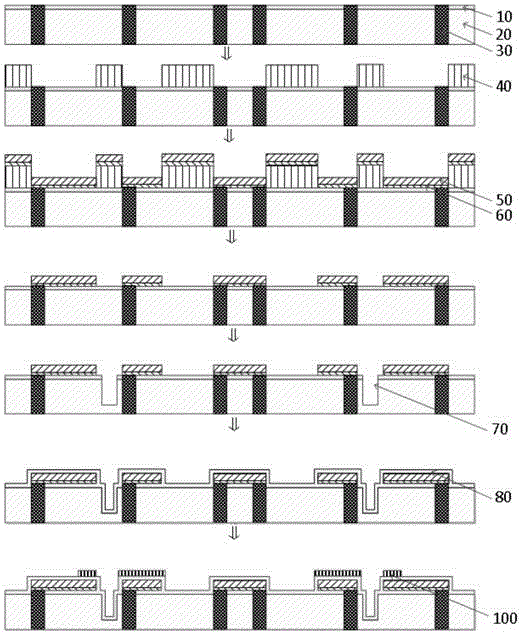

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

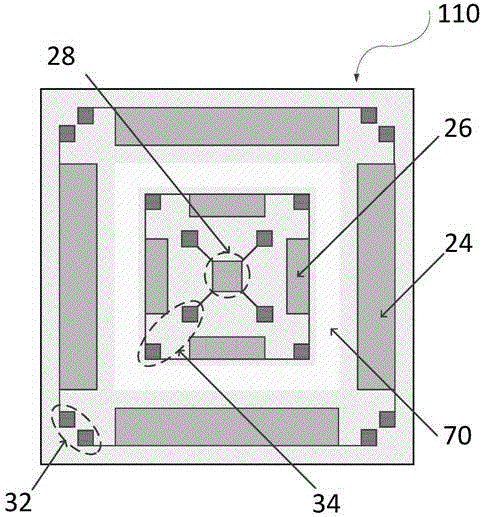

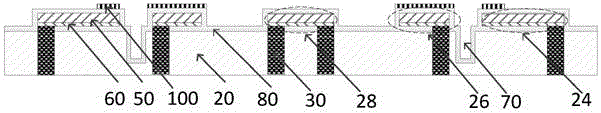

[0040] Such as Figure 1-6As shown, a MEMS wind speed and direction sensor structure based on wafer-level packaging, including a silicon chip 110 and a ceramic chip;

[0041] The silicon chip 110 includes a silicon wafer 20 and a silicon dioxide thermal insulation layer 10, the silicon dioxide thermal insulation layer 10 is arranged on the silicon wafer 20, and the silicon dioxide thermal insulation layer 10 is provided with a heating element 26 for generating heat. Temperature measuring element 28 and heat sensing temperature measuring element 24, a central temperature measuring element 28 is located at the center of the square silicon chip 110, four heating elements 26 and four heat sensing temperature measuring elements 24 are all centered on the central temperature measuring element 28 The center of the center is uniformly arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com