Ultraviolet-transmission heat-insulation film for ultraviolet curing

A heat-insulating film and ultraviolet technology, applied in optical components, optics, instruments, etc., can solve problems such as unsatisfactory cooling effect, achieve reasonable and feasible technical solutions, stable product performance, and reduce absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be further described in detail below in conjunction with the examples.

[0028] The concrete technical index requirement of the embodiment of the present invention is:

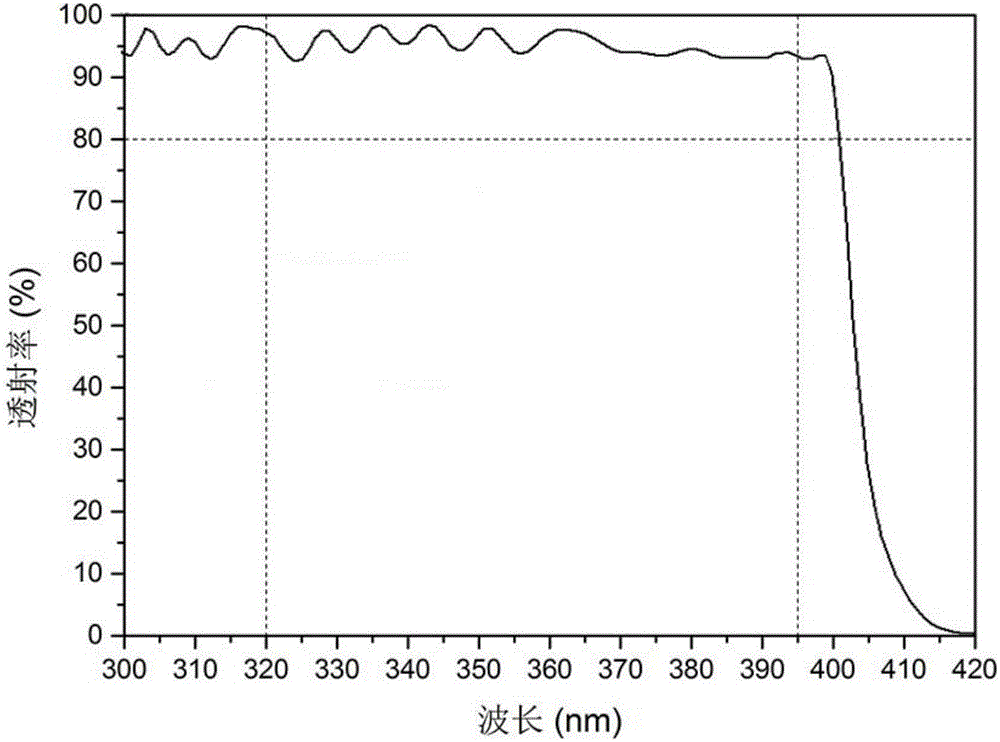

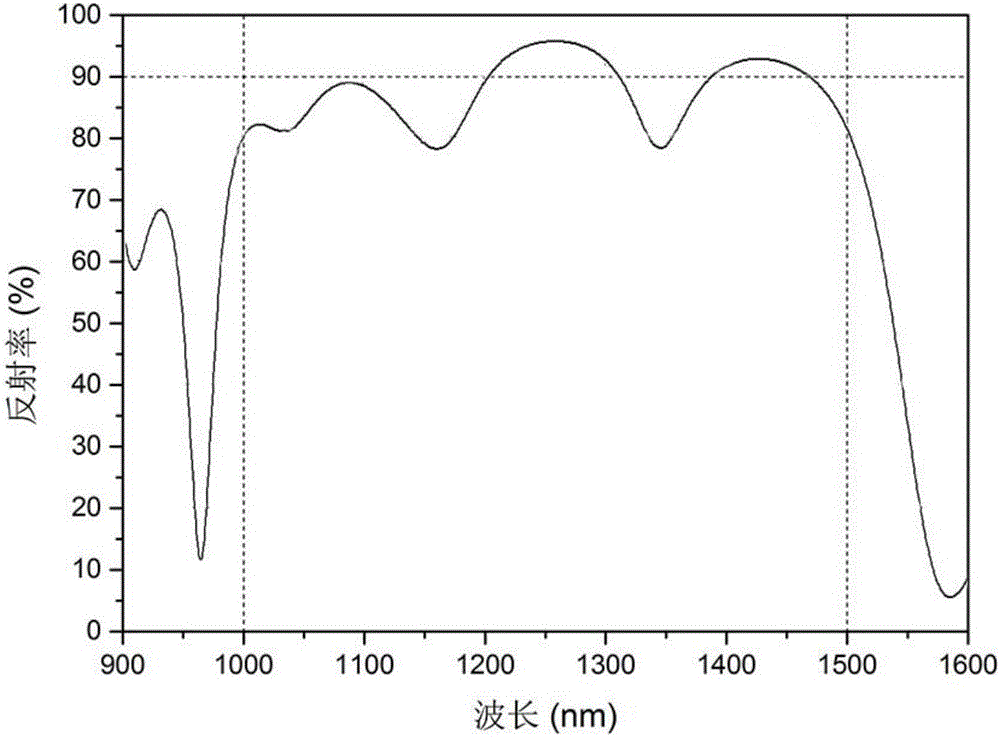

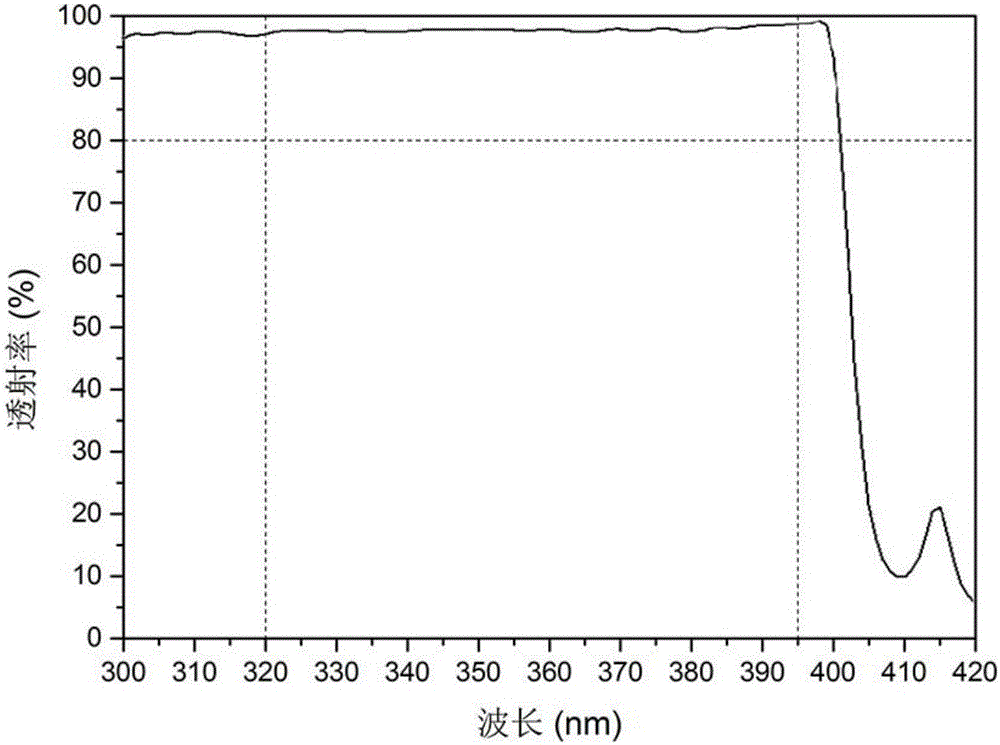

[0029] wavelength(nm) Transmittance and reflectivity requirements 320-395 T≥80% 1000-1500 R≥90%

[0030] The base material is JGS-1 quartz crystal.

[0031] According to technical requirements, when designing the film system, it is necessary to consider not only the high transmission in the ultraviolet band, but also the high reflection in the near-infrared wide spectral band. Glass is used as the substrate, choose Ta which absorbs less in the ultraviolet (320-395nm) and near-infrared (1000-1500nm) bands, and can produce high-reliability films 2 o 5 and SiO 2 The materials are used as high and low refractive index materials respectively. The overall film system adopts a post-cut film structure, and the reflection ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com