Liquid crystal display device and preparation method thereof

A technology of a liquid crystal display device and a manufacturing method, which are applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of poor display of liquid crystal displays and reduce the contamination rate of liquid crystals, so as to reduce poor display and improve product yield and quality. , the effect of reducing the rate of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

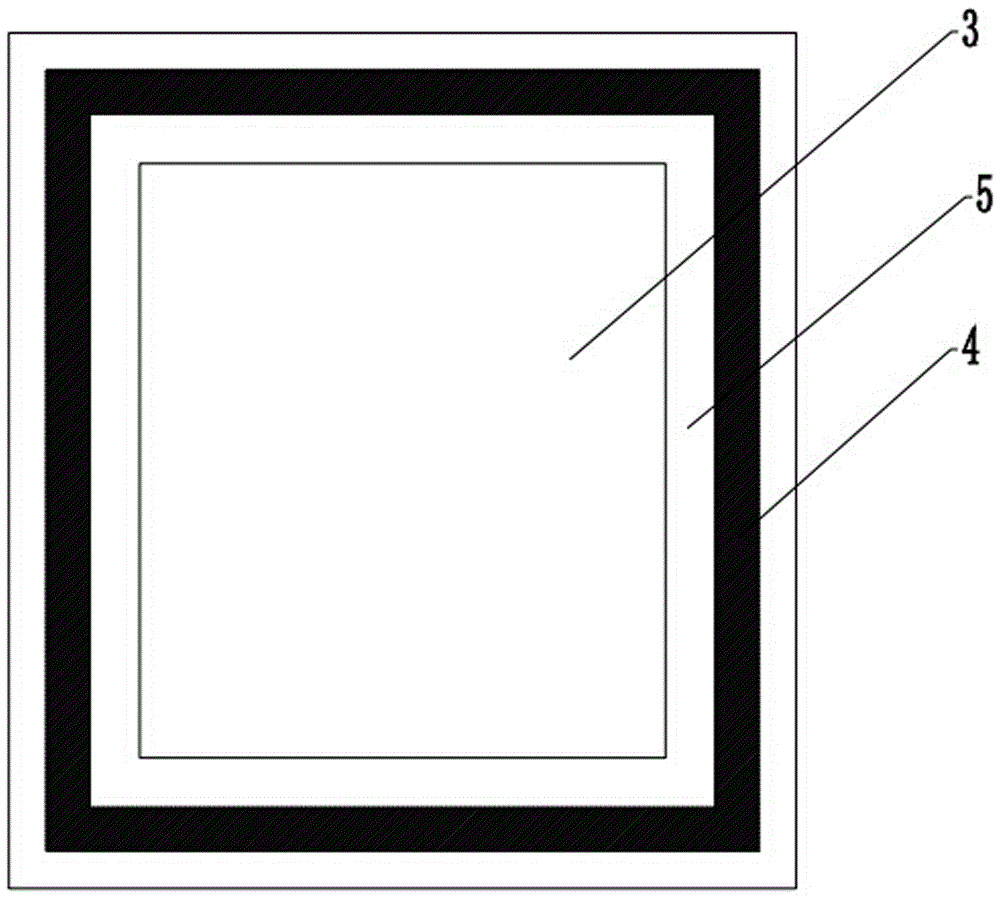

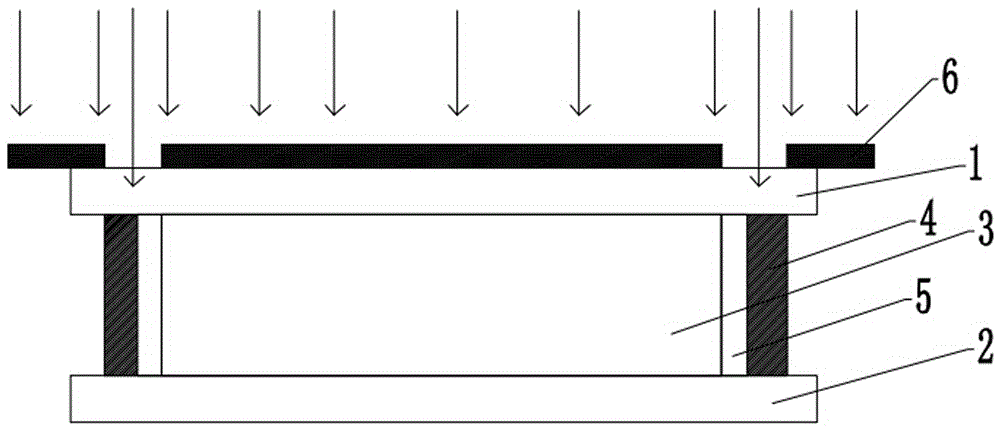

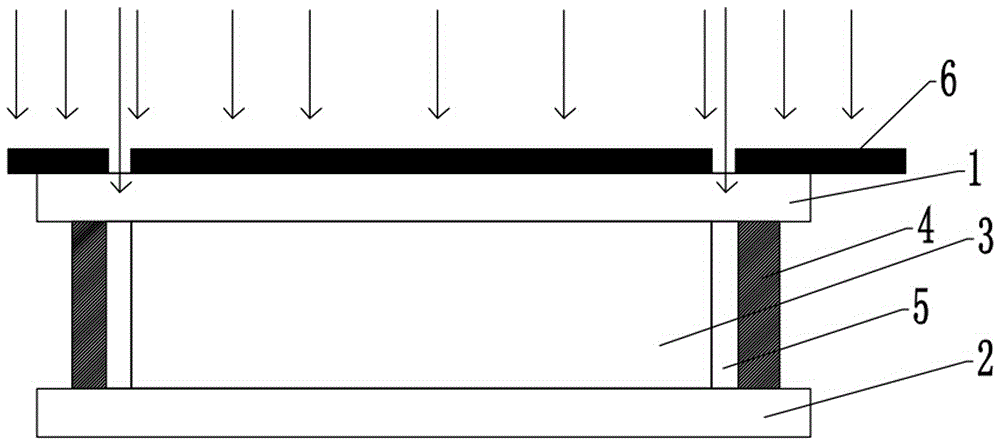

[0050] A method for manufacturing a liquid crystal display device, comprising the following steps:

[0051] Step 1: Provide an array substrate, a color filter substrate, and a liquid crystal composition for use; wherein, the liquid crystal composition is a mixture of a liquid crystal material and a polymer system, and the polymer system is: epoxy acrylate, methacrylic acid- β-hydroxyethyl ester and benzophenone, wherein the content of epoxy acrylate in the liquid crystal composition is 0.08wt%, the content of methacrylic acid-β-hydroxyethyl ester in the liquid crystal composition is 0.02wt%, diphenylmethane The content of ketone in the liquid crystal composition is 0.001wt%.

[0052] Step 2: Using ODF technology, coat the frame glue on the array substrate and instill the liquid crystal composition on the color filter substrate, or drip the liquid crystal composition on the array substrate and apply the frame glue on the color filter substrate, and then the array substrate and ...

Embodiment 2

[0055] A method for manufacturing a liquid crystal display device, comprising the following steps:

[0056] Step 1: Provide an array substrate, a color filter substrate, and a liquid crystal composition for use; wherein, the liquid crystal composition is a mixture of a liquid crystal material and a polymer system, and the polymer system is: polyurethane acrylate, 1,6-hexyl Diol diacrylate and acetophenone, wherein the content of urethane acrylate in the liquid crystal composition is 1.96wt%, the content of 1,6-hexanediol diacrylate in the liquid crystal composition is 0.04wt%, and the content of acetophenone in the liquid crystal composition 1wt%。 Liquid crystal composition content of 0. 1wt%.

[0057] Step 2: Using ODF technology, coat the frame glue on the array substrate and instill the liquid crystal composition on the color filter substrate, or drip the liquid crystal composition on the array substrate and apply the frame glue on the color filter substrate, and then the a...

Embodiment 3

[0060] A method for manufacturing a liquid crystal display device, comprising the following steps:

[0061] Step 1: Provide an array substrate, a color filter substrate, and a liquid crystal composition for use; wherein, the liquid crystal composition is a mixture of a liquid crystal material and a polymer system, and the polymer system is: polyester acrylate, trimethylol Propane triacrylate and benzophenone, wherein the content of polyester acrylate in the liquid crystal composition is 0.47wt%, the content of trimethylolpropane triacrylate in the liquid crystal composition is 0.03wt%, and the content of benzophenone in the 05wt%。 Liquid crystal composition content of 0. 05wt%.

[0062] Step 2: Using ODF technology, coat the frame glue on the array substrate and instill the liquid crystal composition on the color filter substrate, or drip the liquid crystal composition on the array substrate and apply the frame glue on the color filter substrate, and then the array substrate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com