Method for preparing graphene-based composite material

A composite material, graphene-based technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, electrical components, etc., to achieve the effects of high energy density, high conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

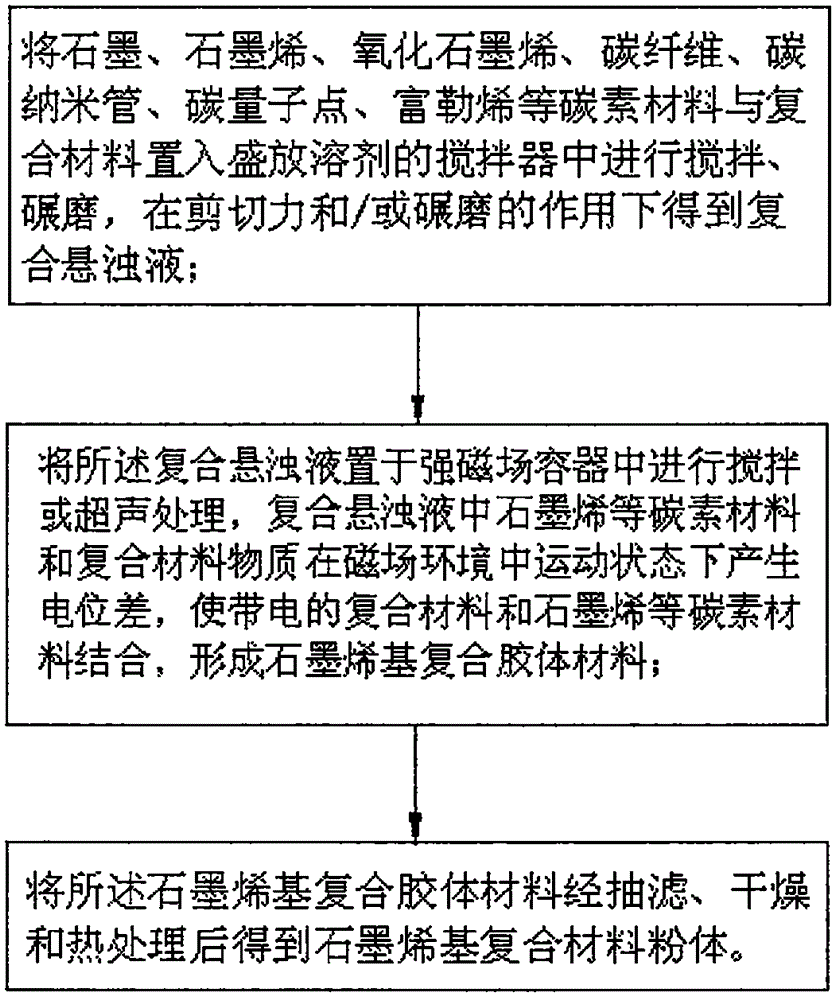

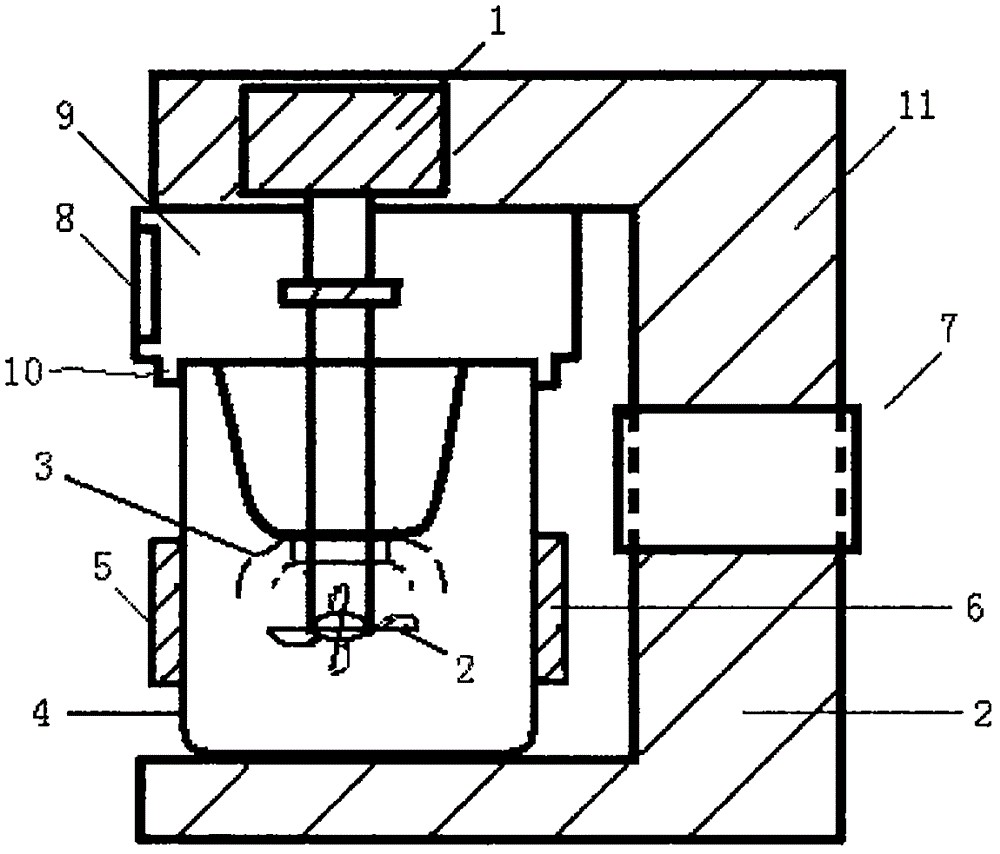

[0041] as attached figure 1 As shown, the embodiment of the present invention discloses a preparation method of a graphene-based composite material, comprising the following steps:

[0042] Carbon materials such as graphite and graphene and composite material precursors are placed in a stirrer containing a solvent for stirring and grinding, and a composite suspension is obtained under the action of shear force and / or grinding;

[0043] Putting the composite suspension into a strong magnetic field container for strong stirring or ultrasonic treatment, and drying to obtain a graphene-based composite powder;

[0044] The graphene oxide-based composite powder is heat-treated to obtain a graphene-based composite material.

[0045] The preparation method of the graphene-based composite material provided by the present invention, the graphene-based composite material prepared by the preparation method of the present invention has high electrical conductivity, large specific surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com