Light-emitting diode chip and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems affecting the photoelectric conversion efficiency of LED chips, low external quantum efficiency of LED chips, and inability to emit light from LED chips, etc. Efficiency, high refractive index contrast, effect of reducing dislocations and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

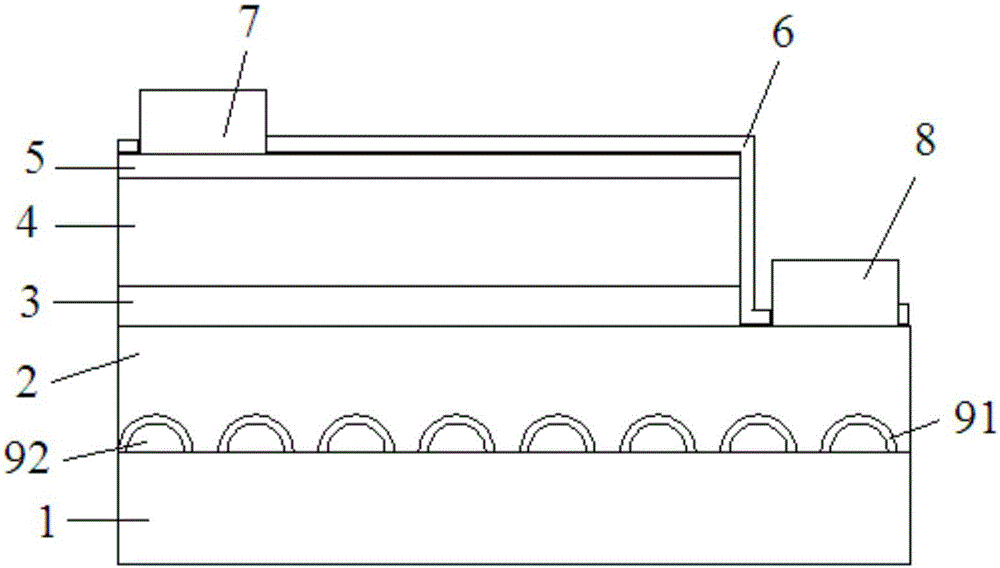

[0037] An embodiment of the present invention provides a light-emitting diode chip, which is suitable for display screens, backlight sources, white light lighting, etc., see figure 1 The light-emitting diode chip includes a substrate 1, and an n-type group III nitride semiconductor layer 2, an active layer 3, a p-type group III nitride semiconductor layer 4, a current spreading layer 5, and an insulating layer stacked on the substrate 1 in sequence. In the passivation layer 6, the p-type group III nitride semiconductor layer 4 is provided with a groove extending to the n-type group III nitride semiconductor layer 2, the first electrode 7 is arranged on the n-type group III nitride semiconductor layer 2, and the second The two electrodes 8 are disposed on the transparent conductive layer 5 .

[0038] In this embodiment, the light-emitting diode chip further includes a light extraction enhancement layer disposed between the substrate 1 and the n-type Group III nitride semiconduc...

Embodiment 2

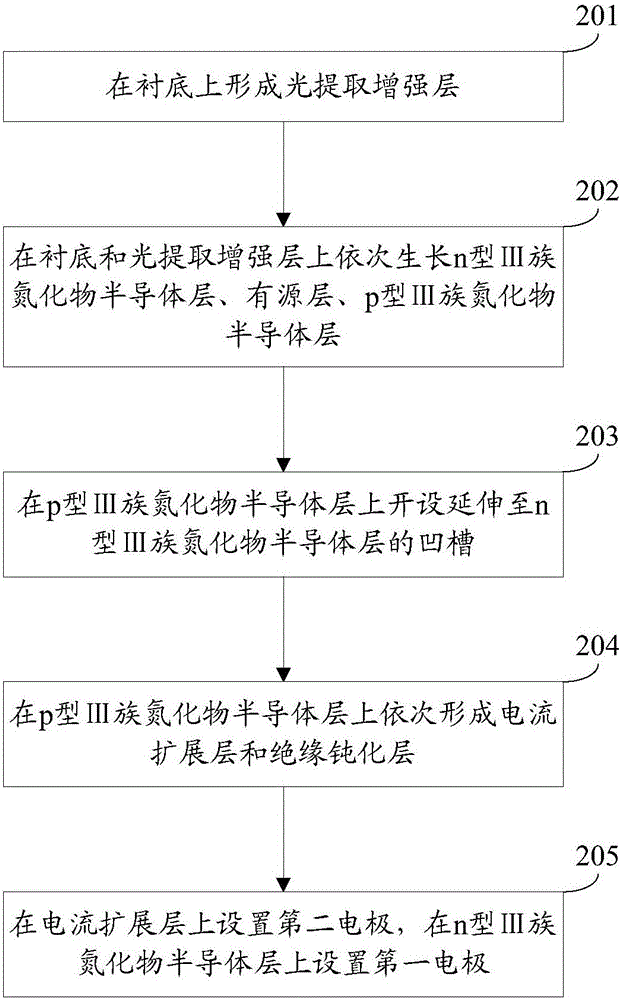

[0057] An embodiment of the present invention provides a method for manufacturing a light-emitting diode chip, which is suitable for manufacturing the light-emitting diode chip provided in Embodiment 1. Refer to figure 2 , the manufacturing method includes:

[0058] Step 201: forming a light extraction enhancement layer on a substrate.

[0059] In this embodiment, the light extraction enhancement layer includes a plurality of curved surface structures distributed in an array, and the curved surface structures together with the substrate form a hollow structure, and the substrate, curved surface structures, and substances in the hollow structure are all transparent.

[0060] Alternatively, the substance within the hollow structure may be air.

[0061] Optionally, the material used for the curved surface structure can be Al 2 o 3 Or AlN.

[0062] Alternatively, the substrate can be Al 2 o 3 crystals.

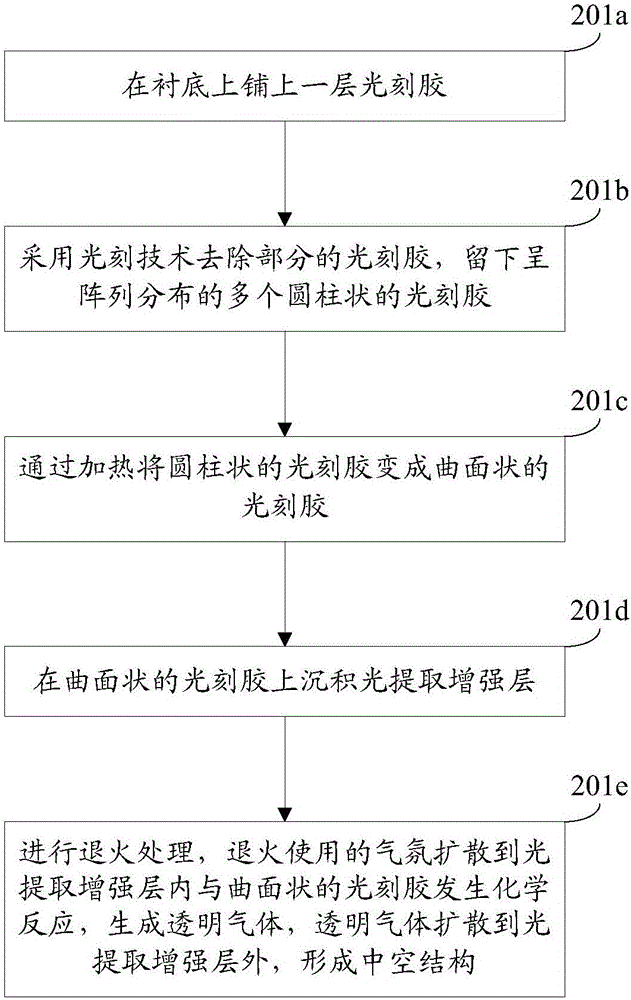

[0063] Optionally, see image 3 , the step 201 may include:

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com