Fullerene Liquid Crystal Compounds Containing Double Bonds and Their Applications

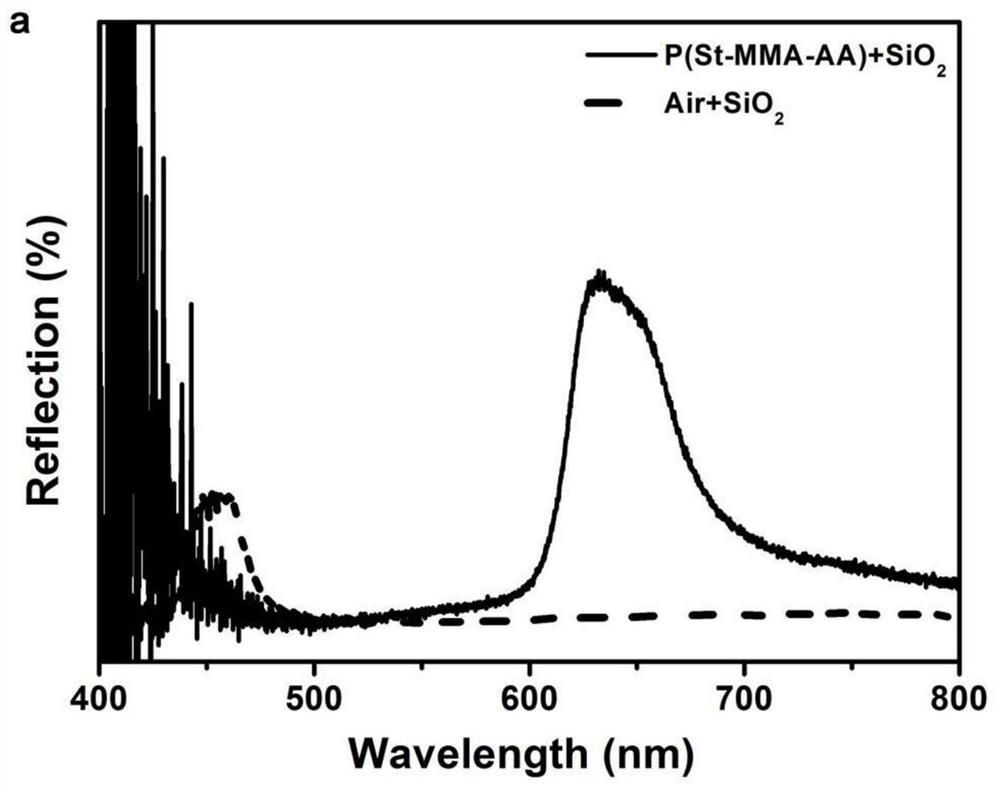

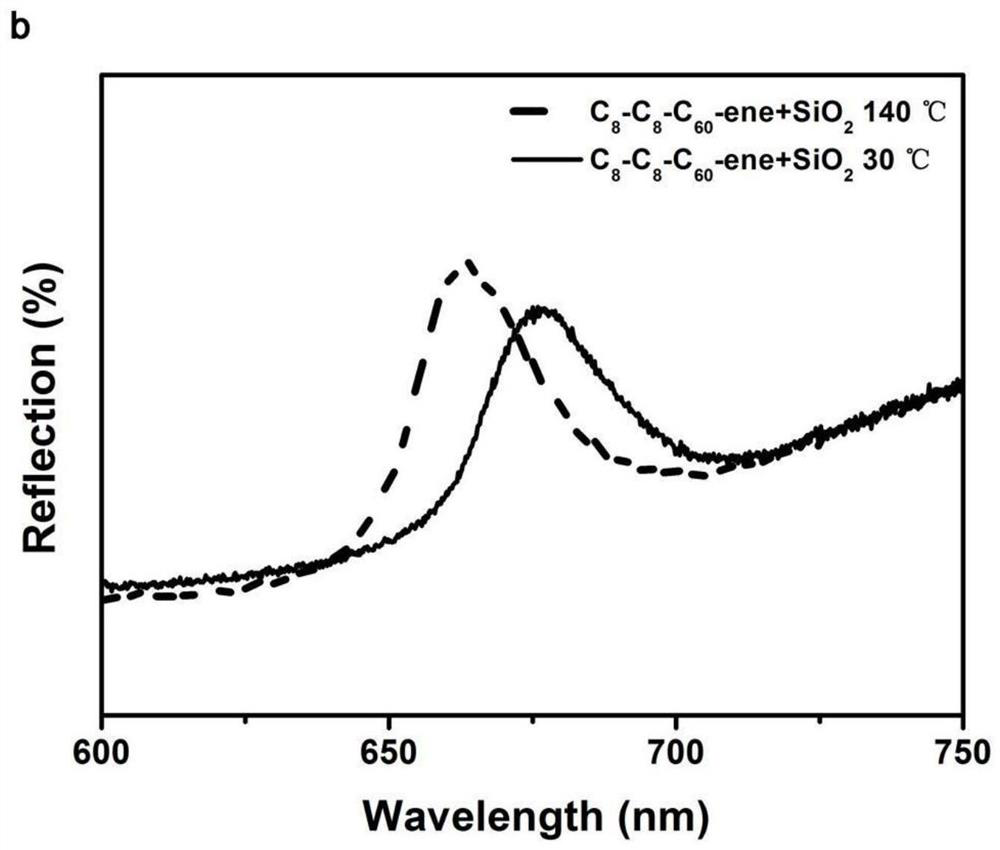

A technology of liquid crystal compounds and fullerenes is applied in the application field of preparing tunable photonic crystals, which can solve the problem of low refractive index contrast of photonic crystals, and achieve the effects of high refractive index contrast and excellent optical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

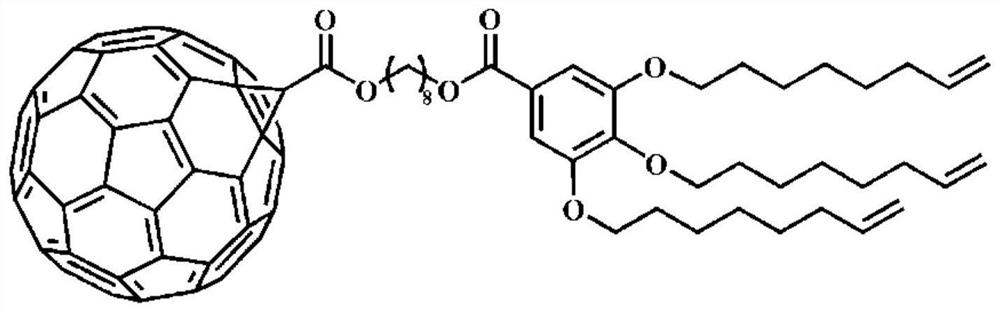

[0045] Example 1 8-(3,4,5-tris(octenyloxy)benzoate) octanediol ester of 1-fullerene acetate (C 8 -C 8 -C 60 -ene) (molecular structure such as Figure 1 Shown) Preparation:

[0046] (1) Synthesis and characterization of 8-bromo-1-octene

[0047] To a THF (100 mL) solution containing potassium tert-butoxide (0.12 mol), was added a THF (50 mL) solution of 1,8-dibromooctane (0.1 mol), and stirred at room temperature for 1 hour. Afterwards, the reaction solution was poured into deionized water (200 mL), extracted with ether (3×60 mL), and the organic phase was collected. The organic phase was sequentially washed with 5% Na 2 CO 3 The solution was washed twice with water and three times with deionized water, dried over anhydrous sodium sulfate, filtered, and rotary evaporated. The collected crude product was distilled by distillation under reduced pressure to obtain the pure product as a colorless liquid. The above reaction process is as follows:

[0048]

[0049] NMR c...

Embodiment 2

[0067] Example 2 Preparation and Performance Testing of Photonic Crystals

[0068] (1) Silicon dioxide (SiO 2 ) preparation of microspheres

[0069] use Monodisperse SiO with different particle sizes prepared by method 2 particles. The specific operation process is as follows: Into a 250mL round bottom flask, add 65.5mL ethanol, 20mL deionized water, 10mL ammonia water, and 4.5mL tetraethyl orthosilicate (TEOS), stir vigorously for 1min, then reduce the stirring speed and react at room temperature for 3h. The reaction solution was centrifuged, then dispersed with absolute ethanol, and centrifuged again. Anhydrous ethanol dispersion and centrifugation were performed twice. Finally, the prepared SiO 2 Particles were preserved in absolute ethanol to obtain SiO 2 particle dispersion. SiO with different sizes obtained by adjusting the ratio of ammonia / deionized water / TEOS 2 particles. Such as Figure 6 shown.

[0070] (2) SiO 2 Preparation of colloidal crystal templat...

Embodiment 3

[0076] Example 3: Preparation and testing of photonic crystals

[0077] (1) Preparation of polymer (P(St-MMA-AA)) microspheres

[0078] In a 250mL three-neck round bottom flask, first add 100mL deionized water and a certain amount of sodium dodecylbenzenesulfonate (SDBS), weigh the monomer styrene (19g, St), methyl methacrylate (1g, MMA), acrylic acid (1.2g, AA), and crosslinking agent divinylbenzene (0.9g, DVB) were mixed evenly, and then the monomer mixture was added to the SDBS aqueous solution. Access to N 2 , after timing for 5 minutes, the system began to heat up while stirring at a stirring speed of 350 rpm. Prepare 0.5 g of ammonium persulfate (APS) in 20 mL of deionized water. When the temperature of the reaction solution was raised to 90° C., 8 mL of APS aqueous solution was added to the reaction solution, and the timing was started. After reacting for 2 hours, 6 mL of APS aqueous solution was added, and after continuing to react for 2 hours, the remaining 6 mL o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com