A kind of preparation method of red photon glaze

A photon and red technology, applied in the field of preparation of red photon glaze, can solve the problems of difficulty in large-scale production, increase the uncontrollability of glaze layer structure, and low sintering temperature of colloidal system, achieve high refractive index contrast, and be easy to promote on a large scale , the effect of a broad commercial market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

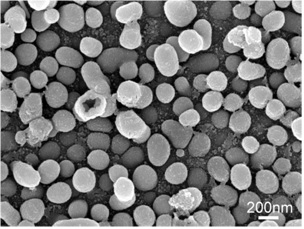

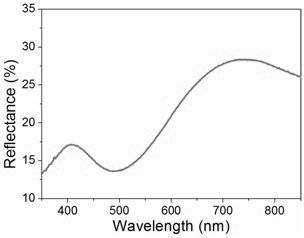

Image

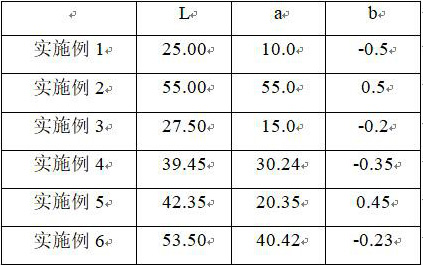

Examples

Embodiment 1

[0021] A preparation method of red photonic glaze, the concrete steps are:

[0022] (1) According to the mass percentage of material composition: kaolin 12.5%, quartz 16.5%, TiO 2 12.5%, limestone 14.5%, albite 15.5%, ZnO 18.5%, talc 10.0%;

[0023] (2) Put the raw materials in step (1) into a ball mill for 1 hour;

[0024] (3) Sieve the glaze slurry milled in step (2) to obtain a glaze slurry with a particle size of <45 μm, and the aging time is 24 hours;

[0025] (4) Applying the processed raw materials in step (3) to the surface of the green body;

[0026] (5) Dry the sample after glazing in step (4) at 60°C for 10 hours;

[0027] (6) Put the sample dried in step (5) into a high-temperature electric furnace for sintering, and then cool naturally with the furnace to obtain a bright red photonic glaze; ℃, the holding time is 30 minutes.

Embodiment 2

[0029] A preparation method of red photonic glaze, the concrete steps are:

[0030] (1) According to the mass percentage of material composition: kaolin 14.0%, quartz 12.5%, TiO 2 18.5%, limestone 9.0%, albite 26.0%, ZnO 12.5%, talc 7.5%;

[0031] (2) Put the raw materials in step (1) into a ball mill for 1 hour;

[0032] (3) Sieve the glaze slurry milled in step (2) to obtain a glaze slurry with a particle size of <45 μm, and the aging time is 24 hours;

[0033] (4) Applying the processed raw materials in step (3) to the surface of the green body;

[0034] (5) Dry the sample after glazing in step (4) at 60°C for 10 hours;

[0035] (6) Put the sample dried in step (5) into a high-temperature electric furnace for sintering, and then cool naturally with the furnace to obtain a bright red photonic glaze; the maximum temperature of the sintering process is 1300 ° C, the holding time is 90 minutes, and the ℃, the holding time is 30 minutes.

Embodiment 3

[0037] A preparation method of red photonic glaze, the concrete steps are:

[0038] (1) According to the mass percentage of material composition: kaolin 15.5%, quartz 15.0%, TiO 2 10.0%, limestone 16.5%, albite 16.5%, ZnO 17.5%, talc 9.0%;

[0039] (2) Put the raw materials in step (1) into a ball mill for 1 hour;

[0040] (3) Sieve the glaze slurry milled in step (2) to obtain a glaze slurry with a particle size of <45 μm, and the aging time is 24 hours;

[0041] (4) Applying the processed raw materials in step (3) to the surface of the green body;

[0042] (5) Dry the sample after glazing in step (4) at 60°C for 10 hours;

[0043] (6) Put the sample dried in step (5) into a high-temperature electric furnace for sintering, and then cool naturally with the furnace to obtain a bright red photonic glaze; ℃, the holding time is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com