Novel positive electrode isolation layer applied to lithium-sulfur battery, and preparation method for novel positive electrode isolation layer

A lithium-sulfur battery and battery positive electrode technology are applied in the field of new positive electrode separator and its preparation to achieve the effects of reducing battery internal resistance, improving ionic conductivity and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

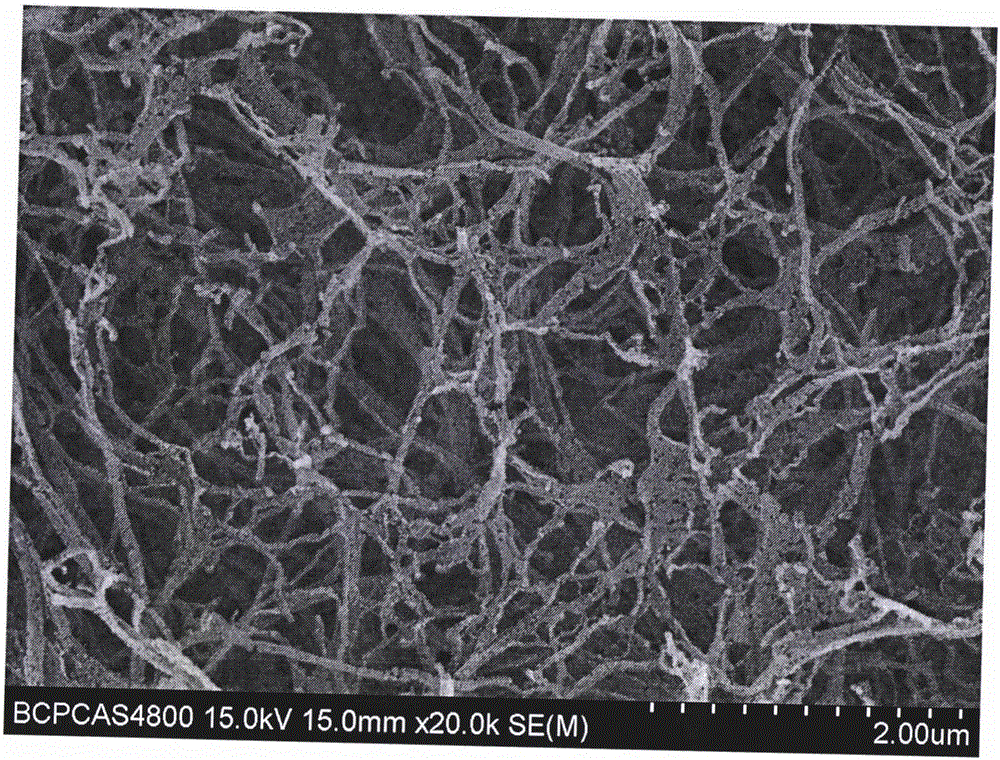

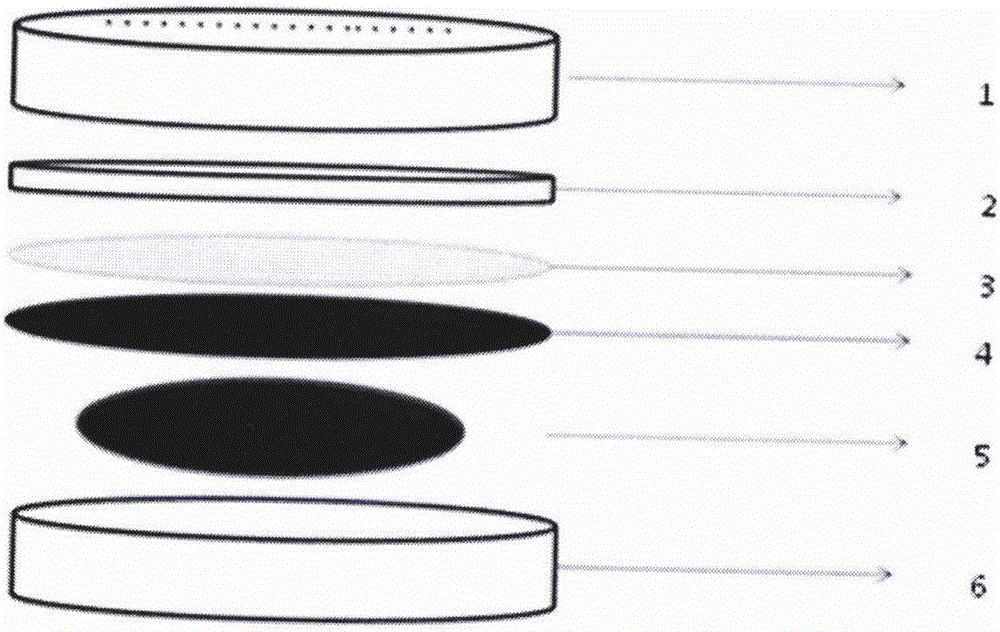

[0025] Nickel nitrate and hexamethylenetetramine are dissolved in deionized water at a mass ratio of 1:4, and the concentration of nickel nitrate is 0.5mol / L; ) placed in the above solution, reacted in a hydrothermal kettle for 10 hours, and the reaction temperature was controlled at 100°C; after the reaction was completed, the bacterial cellulose was quickly frozen with liquid nitrogen to maintain its shape, and then placed in a freeze dryer for freeze-drying; after drying The bacterial cellulose was reacted in a muffle furnace at 300°C for 3 hours; finally, the bacterial cellulose was carbonized in a tube furnace protected by argon for 4 hours, the carbonization temperature was set at 900°C, and the heating rate of the above two steps was set at 5°C / min. Obtain the functional interlayer (wherein nickel oxide content is 12%wt, figure 1 It is the SEM photo of the interlayer, and the nanoscale network structure is clearly seen), which is cut into the size of the separator and ...

Embodiment 2

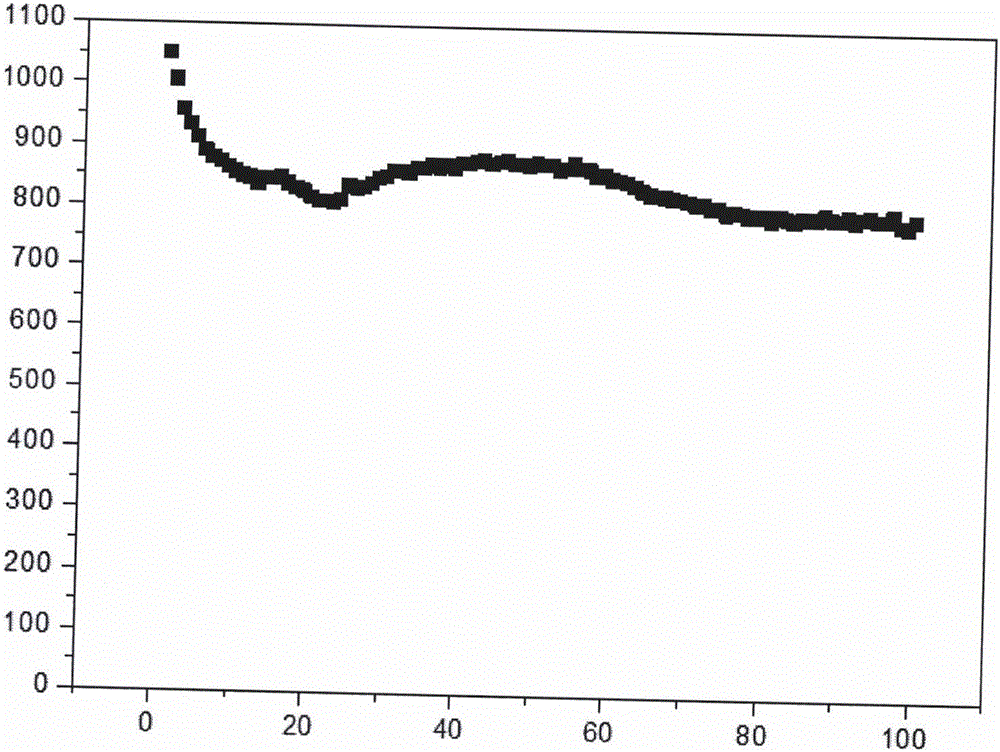

[0027] Cobalt nitrate and hexamethylenetetramine are dissolved in deethylene glycol in a mass ratio of 1:5, and the concentration of cobalt nitrate is 1mol / L; 10) Place in the above solution, react in a hydrothermal kettle for 4 hours, and control the reaction temperature at 80°C; after the reaction is completed, the bacterial cellulose is quickly frozen with liquid nitrogen to maintain its shape, and then placed in a freeze dryer to freeze-dry; dry The final bacterial cellulose was reacted in a muffle furnace at 250 °C for 1 h; finally, the bacterial cellulose was carbonized in a tube furnace protected by argon for 2 h, and the carbonization temperature was set at 1000 °C. The heating rate of the above two steps Set to 4°C / min. Obtain a functional interlayer coated with cobalt oxide (the content of cobalt oxide is 15%wt), cut it into the size of the diaphragm and place it between the diaphragm and the positive electrode material, assemble it into a battery, and test its elect...

Embodiment 3

[0029] Manganese oxalate and ammonia water were dissolved in deethylene glycol at a mass ratio of 1:6, and the concentration of manganese oxalate was 2mol / L; the bacterial cellulose (mass ratio with deionized water was about 1:12) was placed in In the above solution, react in a hydrothermal kettle for 4 hours, and the reaction temperature is controlled at 60°C; after the reaction is completed, the bacterial cellulose is quickly frozen with liquid nitrogen to maintain its shape, and then placed in a freeze dryer to freeze-dry; the dried bacterial cellulose The element was reacted in a muffle furnace at 100 °C for 4 h; finally, the bacterial cellulose was carbonized in a tube furnace protected by argon for 5 h, the carbonization temperature was set at 700 °C, and the heating rate of the above two steps was set at 7 °C / min. Obtain a functionalized interlayer coated with manganese oxide (manganese oxide content is 16%wt), cut it into the size of the diaphragm and place it between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com