Solar-pumped composite crystal with high absorption efficiency and radiating performance and preparation thereof

A technology of heat dissipation performance and composite crystal, applied in the field of lasers, can solve the problems of strong thermal conductivity and can not achieve complete heat insulation, and achieve the effect of improving heat dissipation, improving the degree of heat dissipation, and improving the degree of temperature equalization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

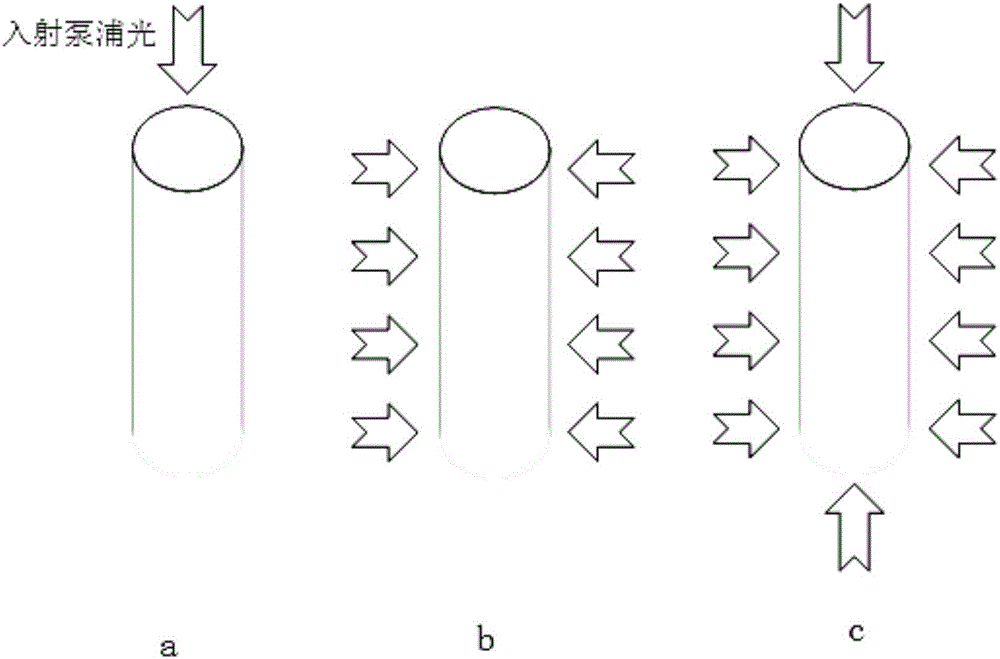

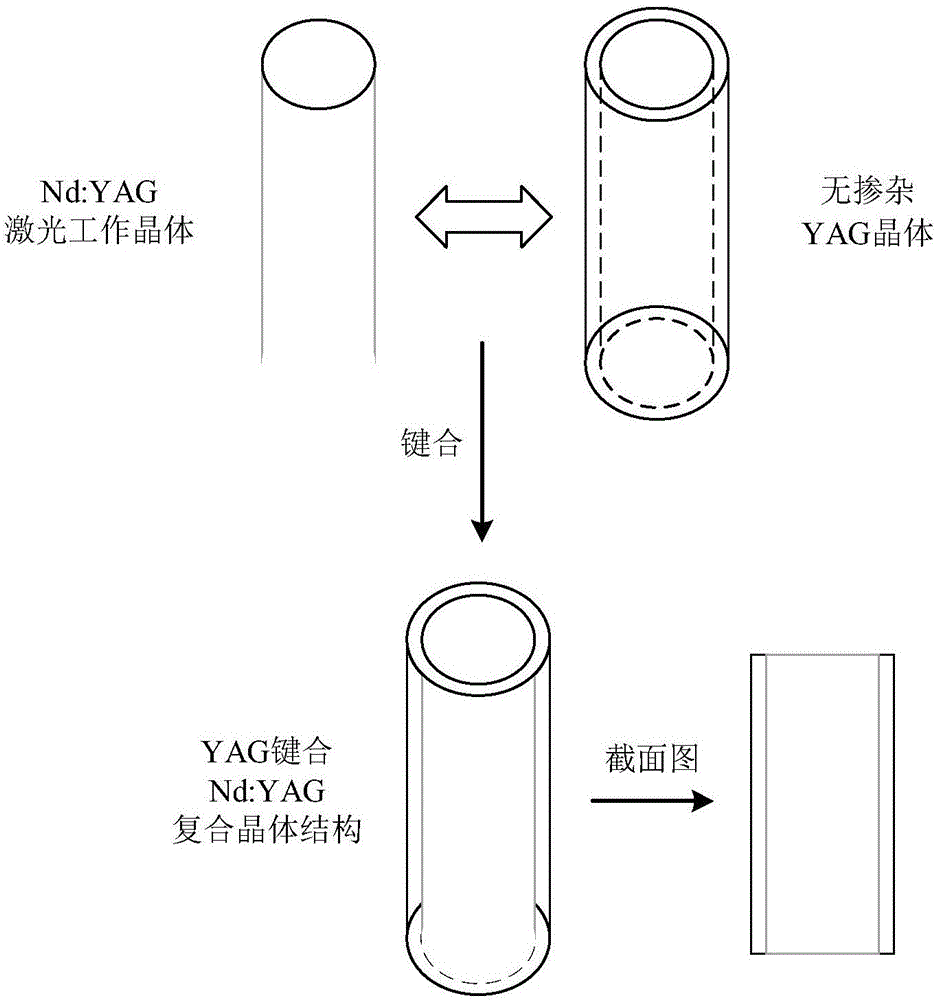

[0032] This embodiment provides a compound crystal structure and preparation method of an end-pumped laser working crystal. The compound crystal is as follows figure 2 As shown, it includes an Nd-doped YAG crystal layer 1 and a YAG crystal layer 2; the YAG crystal layer 2 is located on the outer wall of the Nd-doped YAG crystal layer 1.

[0033] The Nd-doped yttrium aluminum garnet crystal layer 1 is a cylinder.

[0034] The Nd-doped yttrium aluminum garnet crystal layer 1 is 8 mm high and 5 mm in diameter.

[0035] The thickness of the yttrium aluminum garnet crystal layer 2 is 1 mm.

[0036] The preparation method of described composite crystal comprises the steps:

[0037] Step 1, respectively preparing the yttrium aluminum garnet crystal layer and the neodymium-doped yttrium aluminum garnet crystal layer;

[0038] Step 2: Bonding the prepared yttrium aluminum garnet crystal layer and the neodymium-doped yttrium aluminum garnet crystal layer to obtain.

[0039]The spec...

Embodiment 2

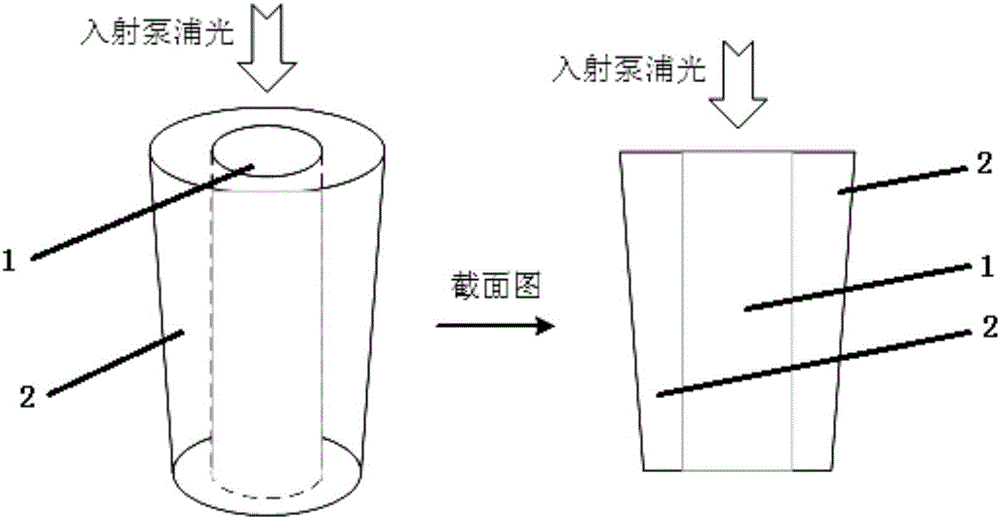

[0042] This embodiment provides a multifaceted pumped laser working crystal compound crystal structure and its preparation method. The compound crystal is as follows Figure 4 As shown, it includes a neodymium-doped yttrium aluminum garnet crystal layer and a yttrium aluminum garnet crystal layer; the yttrium aluminum garnet crystal layer is located on the outer wall of the neodymium-doped yttrium aluminum garnet crystal layer.

[0043] The Nd-doped yttrium aluminum garnet crystal layer is a cylinder.

[0044] The Nd-doped yttrium aluminum garnet crystal layer is 10mm high and 6mm in diameter.

[0045] The thickness of the yttrium aluminum garnet crystal layer located on the outer wall of the neodymium-doped yttrium aluminum garnet crystal layer is: the thickness decreases from 2 mm to 1 mm along the light incident direction.

[0046] The preparation method of described composite crystal comprises the steps:

[0047] Step 1, respectively preparing the yttrium aluminum garnet...

Embodiment 3

[0052] This embodiment provides a multifaceted pumped laser working crystal compound crystal structure and its preparation method. The compound crystal is as follows Figure 4 As shown, it includes a neodymium-doped yttrium aluminum garnet crystal layer and a yttrium aluminum garnet crystal layer; the yttrium aluminum garnet crystal layer is located on the outer wall and the top wall of the neodymium-doped yttrium aluminum garnet crystal layer.

[0053] The Nd-doped yttrium aluminum garnet crystal layer is a cylinder.

[0054] The Nd-doped yttrium aluminum garnet crystal layer is 10mm high and 6mm in diameter.

[0055] The thickness of the yttrium aluminum garnet crystal layer located on the outer wall of the neodymium-doped yttrium aluminum garnet crystal layer is: the thickness decreases from 2 mm to 1 mm along the light incident direction.

[0056] The thickness of the yttrium aluminum garnet crystal layer located on the top wall of the neodymium-doped yttrium aluminum gar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com