Adhesive sheet for cooling

A patch and sticking technology, which is applied to cooling appliances for therapeutic treatment, sheet-like delivery, contraceptives, etc., can solve problems such as impaired cooling sensation, and achieve high cooling effect and good cooling sensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1~13

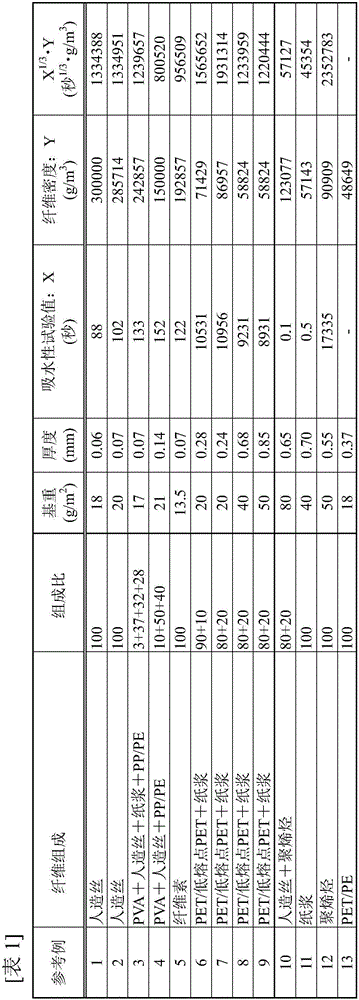

[0083] "Reference Examples 1-13: Fiber Sheet Layer"

[0084] Reference example 1: Rayon (basis weight 18g / m 2 , Thickness 0.06mm)

[0085] Reference example 2: Rayon (basis weight 20g / m 2 , Thickness 0.07mm)

[0086] Reference example 3: Polyvinyl alcohol (PVA) + rayon + pulp + (polypropylene (PP) (core) / polyethylene (PE) (sheath)) = 3+37+32+28 (mass%) ( Basis weight 17g / m 2 , Thickness 0.07mm)

[0087] Reference example 4: PVA+rayon+(PP(core) / PE(sheath))=10+50+40 (mass%) (basis weight 21g / m 2 , Thickness 0.14mm)

[0088] Reference Example 5: Cellulose (Basis Weight 13.5g / m 2 , Thickness 0.07mm)

[0089] Reference example 6: (Polyethylene terephthalate (PET (core)) / low melting point PET (sheath)) + pulp = 90 + 10 (mass%) (basis weight 20g / m 2 , Thickness 0.28mm)

[0090] Reference example 7: (PET (core part) / low melting point PET (sheath part)) + pulp=80+20 (mass%) (basis weight 20g / m 2 , Thickness 0.24mm)

[0091] Reference example 8: (PET (core part) / low melting point PET (sheath part))...

Embodiment 1~9、 comparative example 1~5

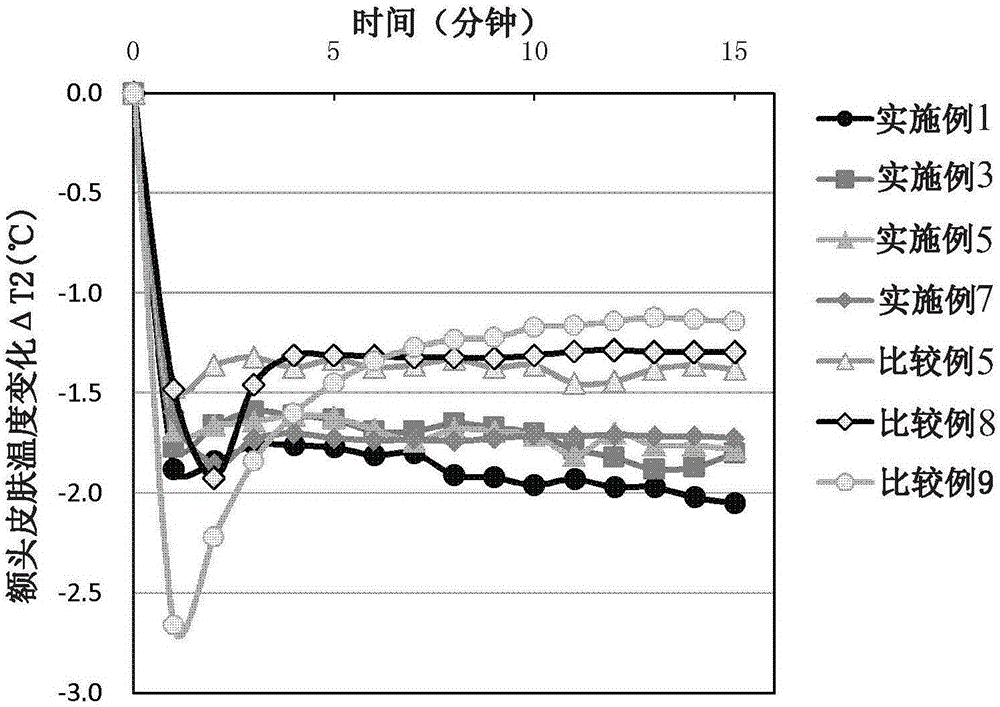

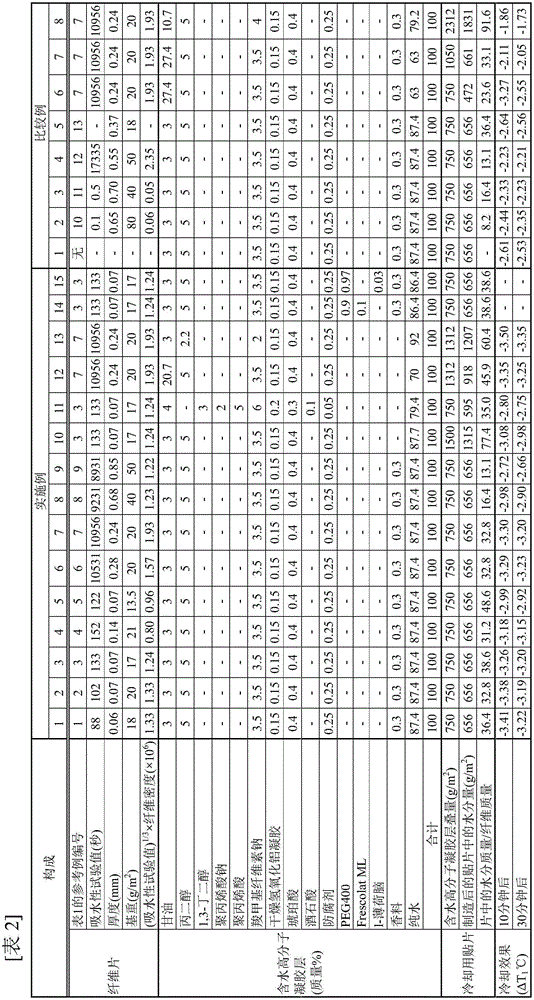

[0099] According to the formula of the water-containing polymer gel shown in Table 2, the water-containing polymer gel was prepared. Next, a water-containing polymer gel was laminated in the amount shown in Table 2 on the fiber sheets of Reference Examples 1 to 13, and after heat curing, a cooling patch was obtained.

[0100] Specifically, first, a mixture of glycerin, propylene glycol in which methyl paraben is dissolved by heating, sodium carboxymethyl cellulose, and dry aluminum hydroxide gel is put into the kneader, and then the succinic acid aqueous solution is added , Prepare uncrosslinked gel stock solution. Next, the obtained uncrosslinked gel stock solution was coated on a polypropylene film and embedded, and the layered amount of the water-containing polymer gel was 750 g / m based on the stock solution using a Baker applicator. 2 (Water content 656g / m 2 ) Method to adjust the thickness to form a sheet. After the obtained sheet was enclosed in an aluminum pillow and seal...

Embodiment 10、11、 comparative example 6、7

[0108] The water-containing polymer gel formed according to the formula shown in Table 2 was used. In Example 10, the layered amount of the water-containing polymer gel was 1500 g / m based on the original solution. 2 (Moisture content 1315g / m 2 The thickness was adjusted in the manner of ). In Example 11, the moisture content of the water-containing polymer gel was set to 79.4% by mass. Except for this, the cooling patch was prepared in the same manner as in Example 3. In addition, in Comparative Example 6, the water content of the water-containing polymer gel was set to 63% by mass, and except for that, the cooling patch was prepared in the same manner as in Example 7. In Comparative Example 7, the water content of the water-containing polymer gel was set to 63% by mass, and the lamination amount of the water-containing polymer gel was 1050 g / m based on the original solution. 2 (Moisture content 661g / m 2 Except for coating and adjusting the thickness in the manner of ), the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com