Ultrapure water production apparatus and ultrapure water production method

A technology for manufacturing equipment and manufacturing methods, which is applied to pure water manufacturing equipment and the field of pure water manufacturing, and achieves the effects of excellent economy, space saving, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

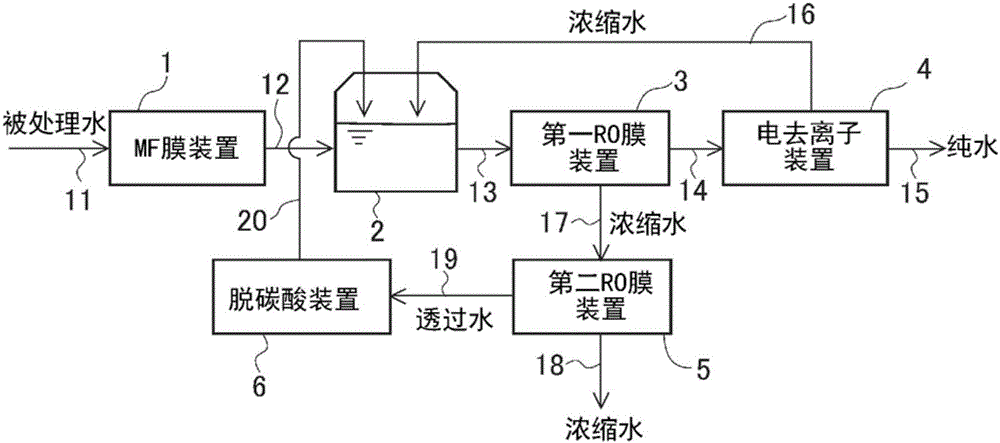

[0061] pass figure 1 The shown pure water production device produces pure water. However, an activated carbon device is installed in the subsequent stage of the MF membrane device 1 .

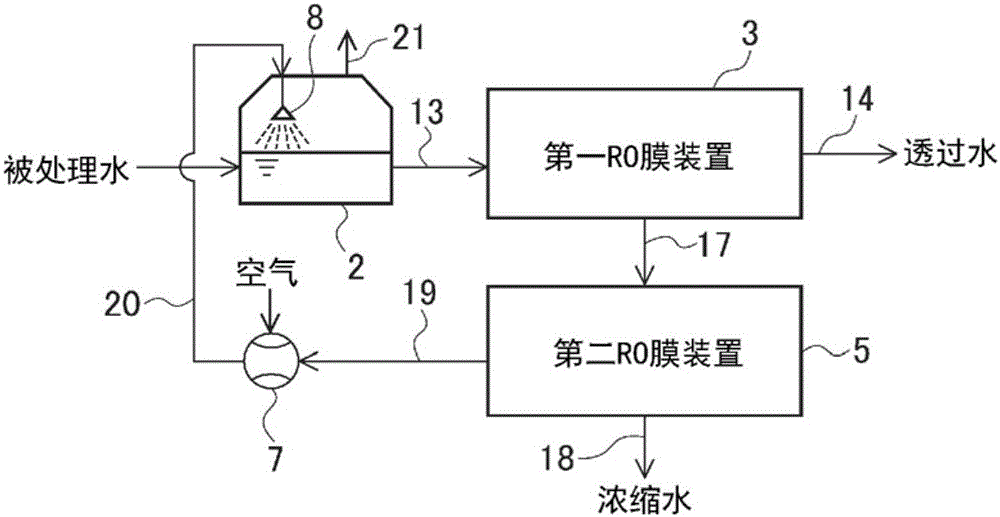

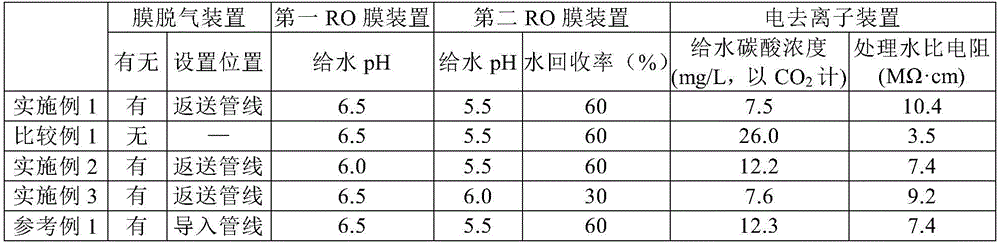

[0062] Tap water (M alkali concentration: 50mgCaCO2) was treated by MF membrane device (manufactured by Kuraray (Kurare), hollow fiber type PVDF membrane, pore size: 0.02μm). 3 / L, silica concentration: 30mg / L) to remove turbidity, remove free chlorine through an activated carbon device, and then pass water through the first RO membrane device (manufactured by Nitto Denko, ES20). The permeated water of the first RO membrane device was passed through an electrodeionization device (manufactured by Kurita Industries, Ltd., KCDI-TC) to obtain pure water. The concentrated water of the first RO membrane device is passed through the second RO membrane device (manufactured by Nitto Denko Corporation, ES20), and passed through the membrane degasser (Calgerde) that is arranged on the return line of the...

Embodiment 2

[0070] Table 1 shows the results in the same manner as in Example 1 except that the pH of the feed water of the first RO membrane device was 6.0.

Embodiment 3

[0072]The pH of the feed water of the second RO membrane device was set to 6.0, and the water recovery rate was set to 30% to prevent the precipitation of silica scale. Except this, the same treatment was carried out as in Example 1, and the results were shown in Table 1. middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com