Heterophase polyurethane composition with reduced foam formation

A composite, two-component polyurethane technology, applied in household appliances, other household appliances, coatings, etc., can solve the problems of damage to material properties, increased heat release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

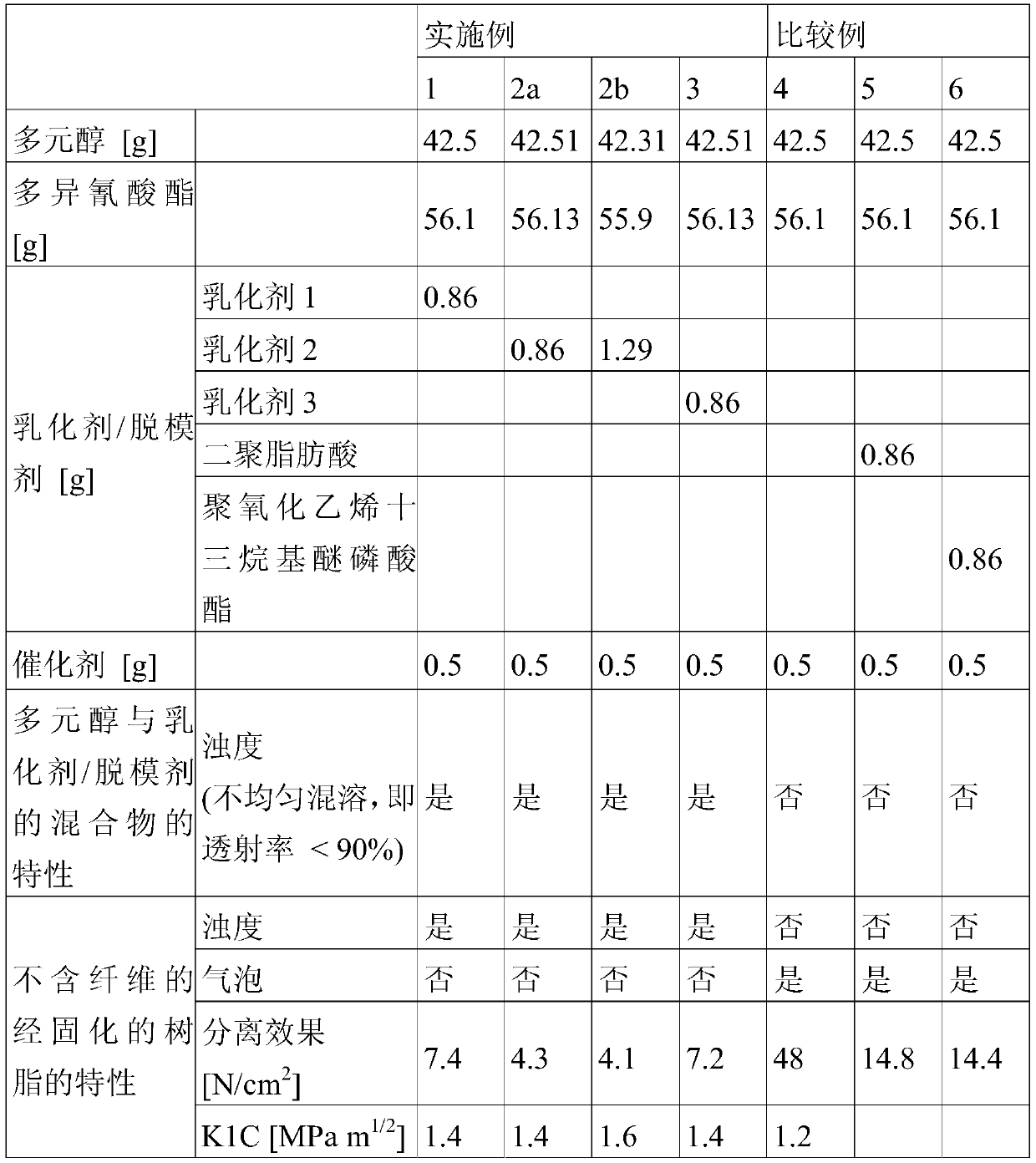

Examples

Embodiment

[0087] raw material

[0088] 1. Polyol: polyether triol, hydroxyl value=550mg KOH / g, viscosity at 25°C=1800mPas (Brookfield25°C, rotor 4, 20rpm), OH equivalent weight=102g, number average molecular weight=300g / mol

[0089] 2. Polyisocyanate: isomeric mixture of MDI and higher functional homologues, NCO content 32% by weight, viscosity at 25° C. = 43 (Brookfield 25° C., spindle 3, 50 rpm)

[0090] 3. Catalyst: solution of dicyclic tertiary amine (DABCO) in polyol (based on solution, 30% by weight of DABCO)

[0091] 4. Emulsifier / release agent:

[0092] - emulsifier 1: difunctional carboxylic acid (C 6 ) and unsaturated fatty acid (average C chain length 18) esterified tetrafunctional polyol

[0093] - Emulsifier 2: Dipentaerythritol fully esterified with oleic acid

[0094] - Emulsifier 3: dimer fatty acid and branched alcohol (average alcohol chain length C 8 ) diester

[0095] - dimer fatty acid

[0096] —polyoxyethylene tridecyl ether phosphate

[0097] Component A: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com