Method for processing sucralose tail gas

A technology of sucralose and treatment method, which is applied in the chemical industry, can solve the problems of high cost and secondary pollution, and achieve the effect of thorough recovery of sulfur dioxide, strong practicability, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

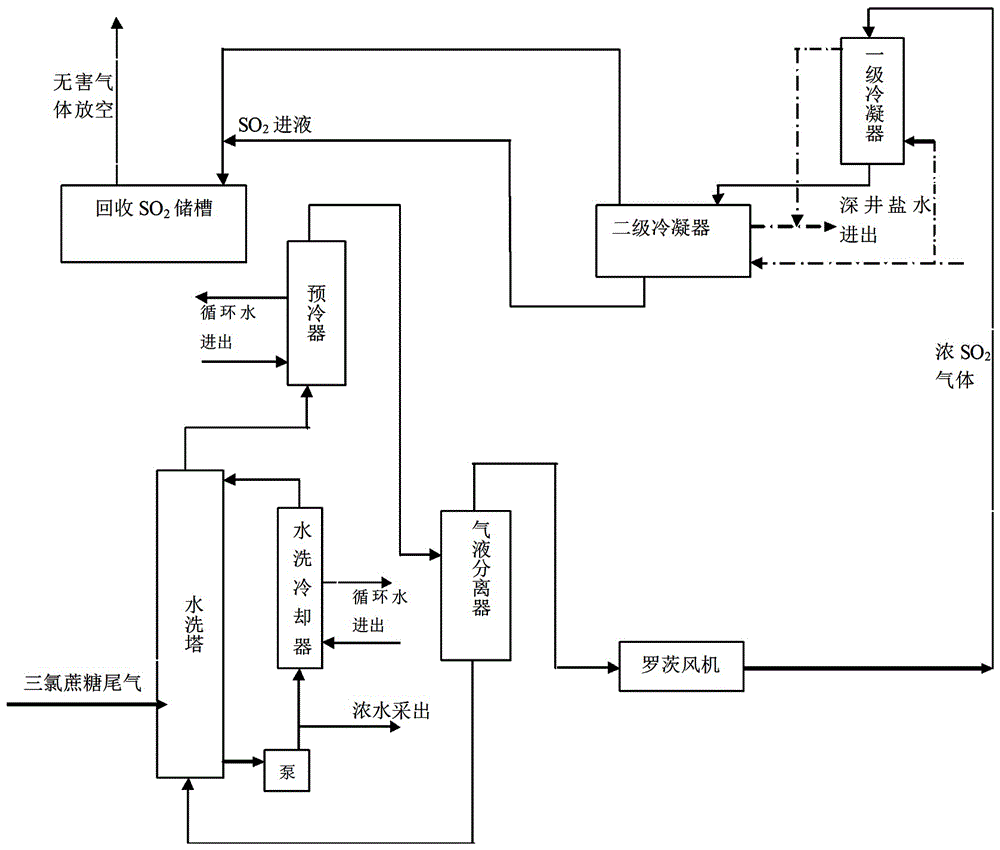

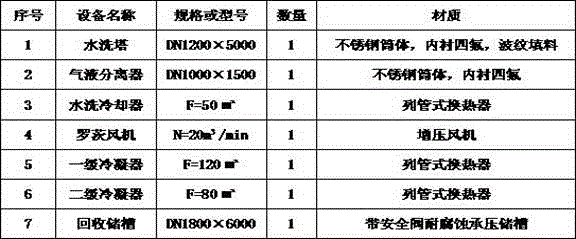

[0017] Such as figure 1 As shown, the equipment used in the present invention is shown in the following table.

[0018]

[0019] The tail gas from sucralose first passes through the water washing tower to wash away the HCl entrained in the gas. The water washing tower is equipped with a circulating water washing cooler and its connected water washing pump to control the washing temperature in the water washing tower at 30°C-38°C. CL-≥500ppm in the washing tower, concentrated water is extracted.

[0020] The tail gas treated by the water scrubber is condensed by a precooler, and then processed by a gas-liquid separator. The separated liquid returns to the water scrubber and the gas enters the Roots blower. The inlet pressure of the roots blower is set at -2kpa during normal operation. When the inlet pressure of the blower shows +1KPa, start the roots blower, open the blower outlet valve, and set the negative pressure of the blower inlet at -2kpa. Concentrated SO pressurized by Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com