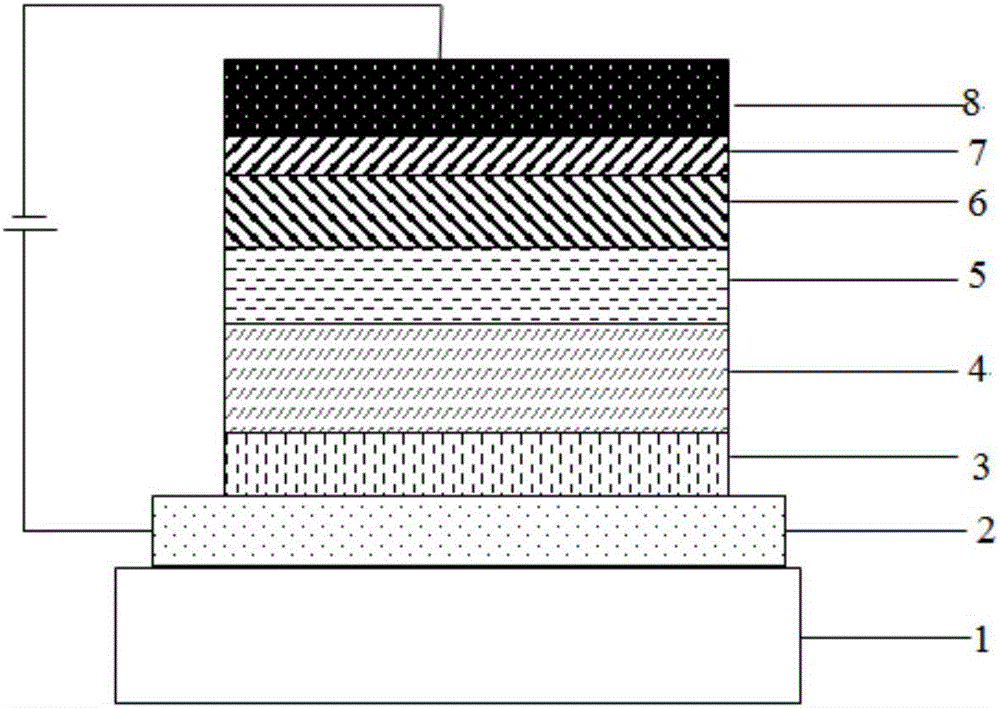

Compound taking anthrone as core and application of compound in OLED device

- Summary

- Abstract

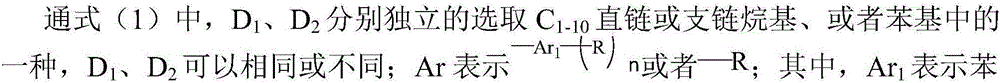

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Synthesis of Example 1 Compound C03

[0069]

[0070] In a 250ml four-neck flask, under a nitrogen atmosphere, add 0.01mol 2-bromo-10,10-dimethyl-10H-anthrone, 0.015mol compound A1, 0.03mol sodium tert-butoxide, 1×10 -4 mol Pd 2 (dba) 3 , 1×10 -4 mol of tri-tert-butylphosphine, 150ml of toluene, heated to reflux for 24 hours, sampling plate, reaction complete, natural cooling, filtration, filtrate rotary evaporation, silica gel column, to obtain the target product with a purity of 99.40% and a yield of 36.90%.

[0071] HPLC-MS: The molecular weight of the material is 686.29, and the measured molecular weight is 686.31.

Embodiment 2

[0072] Example 2 Synthesis of Compound C11

[0073]

[0074] In a 250ml four-neck flask, under nitrogen atmosphere, add 0.01mol 3-(3-bromophenyl)-10,10-diphenyl-10H-anthrone, 0.015molA2, 0.03mol sodium tert-butoxide, 1×10 -4 mol Pd 2 (dba) 3 , 1×10 -4 mol tri-tert-butylphosphine, 150ml toluene, heating and reflux for 24 hours, sampling point plate, reaction complete, natural cooling, filtration, filtrate rotary evaporation, silica gel column, to obtain the target product with a purity of 97.6% and a yield of 45.8%.

[0075] HPLC-MS: The molecular weight of the material is 912.41, and the measured molecular weight is 912.59.

Embodiment 3

[0076] Synthesis of Example 3 Compound C24

[0077]

[0078] In a 500ml four-neck flask, under an atmosphere of nitrogen gas, add 0.01mol 3-bromo-10,10-diphenyl-10H-anthrone, 0.015molA3, dissolve with a mixed solvent (180ml toluene, 90ml ethanol), and then Add 0.03mol Na 2 CO 3 aqueous solution (2M), then add 0.0001mol Pd (PPh 3 ) 4 , heated to reflux for 10-24 hours, sampled and plated, the reaction was complete. Naturally cooled, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain the target product with an HPLC purity of 99.50% and a yield of 56.5%.

[0079] HPLC-MS: The molecular weight of the material is 683.32, and the measured molecular weight is 683.42.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com