Fuel cell parameter control system and working method thereof

A parameter control and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of gas residue, danger, and safety improvement, and achieve the effect of stable performance and safe method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

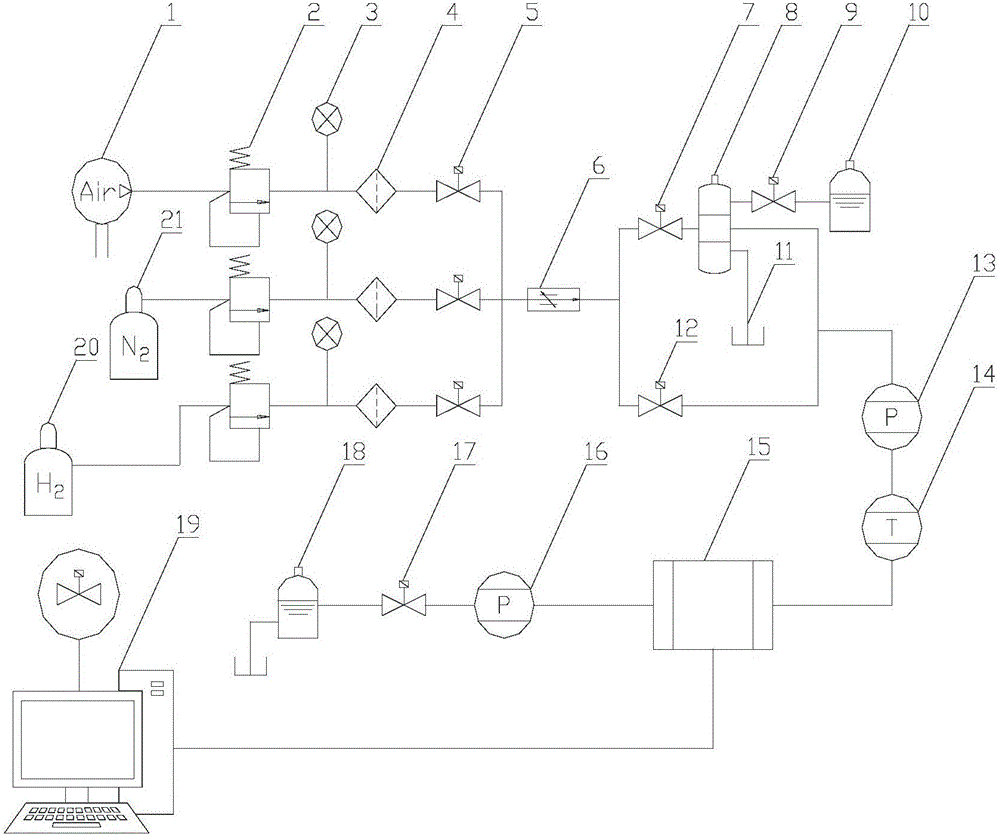

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0025] The present invention takes a proton exchange membrane fuel cell as an example to introduce its parameter control system and working method, but this specific embodiment should not be regarded as a limitation to the technical solution of the present invention.

[0026] according to figure 1 , the fuel cell parameter control system of the present invention mainly includes an air compressor 1, a pressure reducing valve 2, a pressure gauge 3, a filter 4, an air supply control valve 5, a flow meter 6, a humidification route control valve 7, a humidifier 8, a water supply Control valve 9, water replenisher 10, manual valve 11, dry gas route control valve 12, pressure sensor one 13, temperature sensor 14, fuel cell stack 15, pressure sensor two 16, back pressure valve 17, water tank 18, PC terminal control With display device 19, hydrogen cylinder 20.

[0027] like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com