A kind of high specific surface sucrose silkworm sand composite carbon material and its preparation method and application

A technology of high specific surface area and composite carbon, which is applied in botany equipment and methods, applications, animal husbandry, etc., can solve the problems of non-target biological damage environment, excessive pesticide residues in agricultural products, and low efficiency of pesticide utilization, etc., and achieve the goal of reducing solvents Effects of consumption, reduction of waste liquid discharge, and improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a high specific surface sucrose silkworm excrement composite material, comprising the following steps,

[0031] (1) in N 2 In the atmosphere, 10.0 g of raw silkworm excrement was raised to 500°C at a heating rate of 5°C / min, kept at 500°C for more than 5.0 hours, and then cooled to room temperature to prepare carbonized silkworm excrement.

[0032] (2) Put 0.25g of sucrose powder and 0.25g of carbonized silkworm excrement into a ball mill jar, add 1.0mL of ZnCl with a mass concentration of 0.25g / L 2 solution; the ball mill jar is sealed and placed in a high-speed mechanical oscillating ball mill to oscillate, the rotating speed is 1000 rpm, and the grafting reaction time is 60min (normal pressure sealing is carried out in the reaction process); the obtained sucrose / ZnCl 2 / Silkworm excrement composite slurry is directly dried at 80°C to obtain crude composite material;

[0033] (3) the obtained composite material crude product in step (2) in N ...

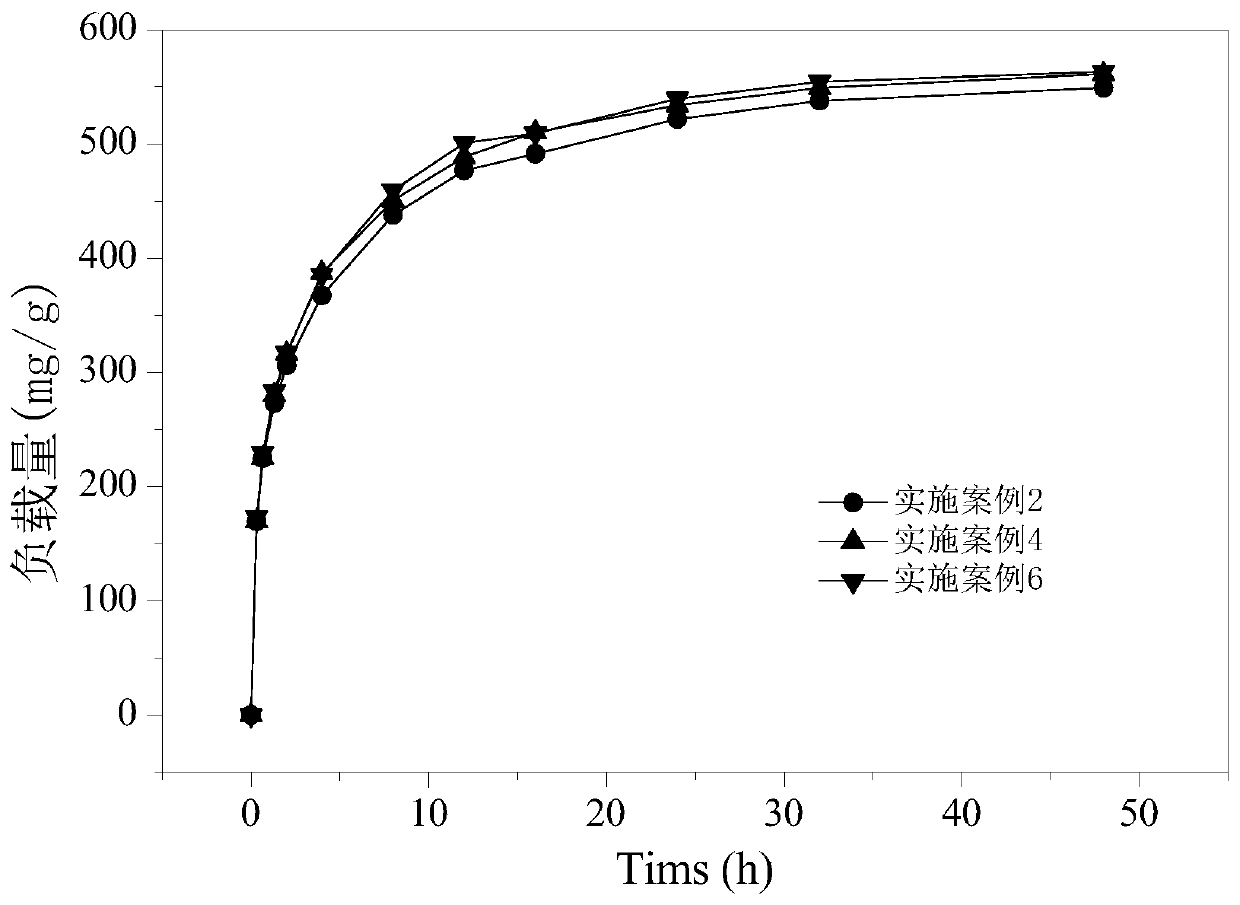

Embodiment 2

[0035] (1) in N 2 In the atmosphere, 10.0 g of raw silkworm excrement was raised to 600°C at a heating rate of 5°C / min, kept at 600°C for more than 4.0 hours, and then cooled to room temperature to prepare carbonized silkworm excrement.

[0036] (2) Put 0.25g of sucrose powder and 0.5g of carbonized silkworm excrement into a ball mill jar, add 3.0mL of ZnCl with a mass concentration of 0.30g / L 2 solution alcohol; the ball mill jar is sealed and placed in a high-speed mechanical oscillating ball mill to oscillate, the rotating speed is 1050 rpm, and the grafting reaction time is 50min (normal pressure sealing is carried out in the reaction process); the obtained sucrose / ZnCl 2 / Silkworm excrement composite slurry was directly dried at 80°C to obtain crude composite material.

[0037] (3) the obtained composite material crude product in step (2) in N 2 In the atmosphere, the temperature was raised to 550°C at a rate of 5°C / min, and kept at 550°C for 4.0 hours. After the natura...

Embodiment 3

[0039] (1) in N 2 In the atmosphere, 10.0 g of raw silkworm excrement was raised to 700°C at a heating rate of 5°C / min, kept at 700°C for more than 3.0 hours, and then cooled to room temperature to prepare carbonized silkworm excrement.

[0040] (2) 0.25g of sucrose powder and 0.75g of carbonized silkworm excrement were placed in a ball mill jar, and 5.5mL of ZnCl with a mass concentration of 0.25g / L was added 2 solution; the ball mill jar is sealed and placed in a high-speed mechanical oscillating ball mill to oscillate, the rotating speed is 1100 rpm, and the grafting reaction time is 45min (normal pressure sealing is carried out in the reaction process); the obtained sucrose / ZnCl 2 / Silkworm excrement composite slurry was directly dried at 90°C to obtain crude composite material.

[0041] (3) the obtained composite material crude product in step (2) in N 2 In the atmosphere, the temperature was raised to 600°C at a rate of 5°C / min, and kept at 600°C for 3.0 hours. After c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com