Air purifying liquid and preparation method thereof

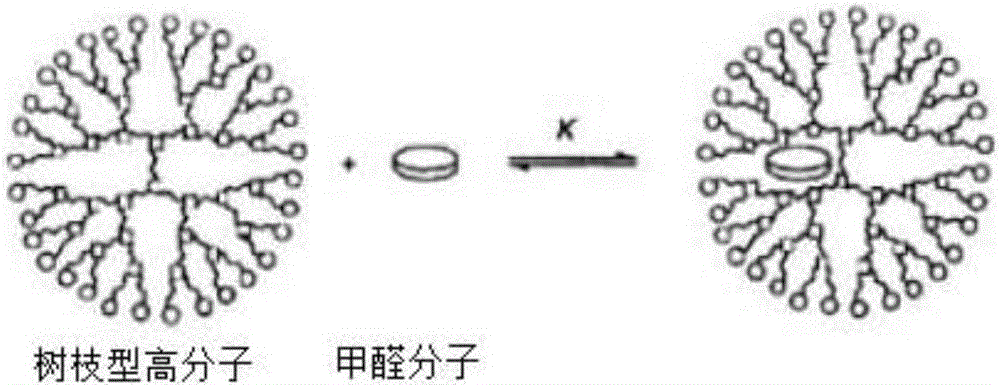

An air purification and chloride technology, applied in the field of air purification, can solve the problems of slow purification speed, poor adsorption capacity, weak formaldehyde purification ability, etc., achieve high purification efficiency, reduce CO2, and facilitate the effect of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

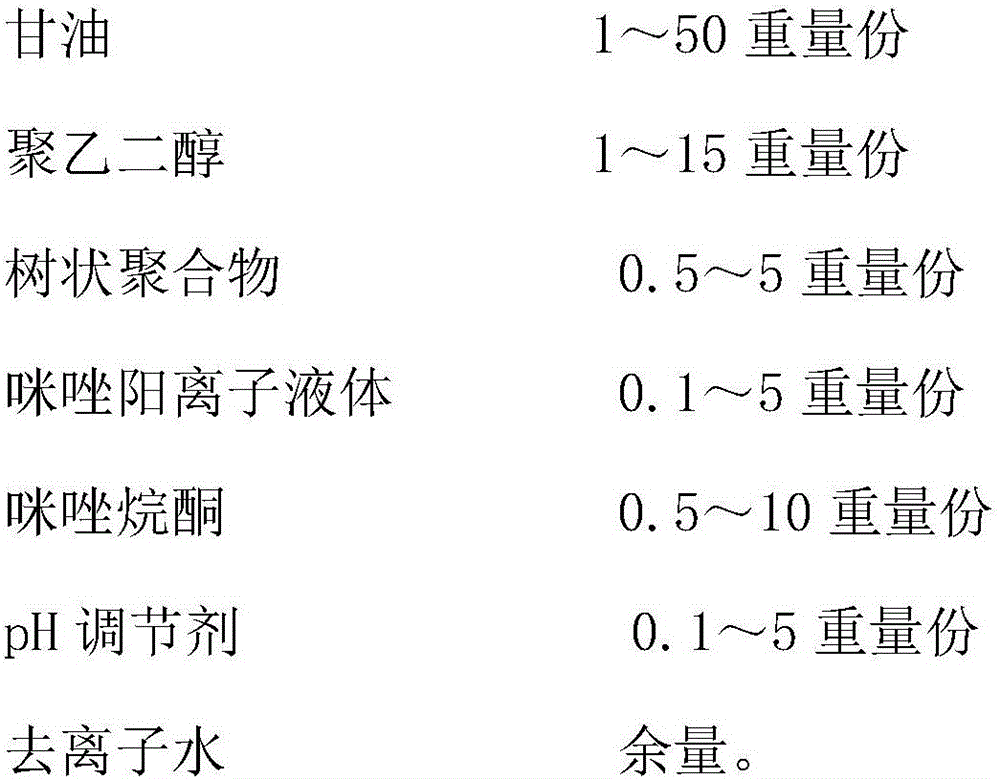

[0037] A kind of air purification liquid, its formula is:

[0038]

[0039]

[0040] A kind of preparation method of air purification liquid, concrete steps are:

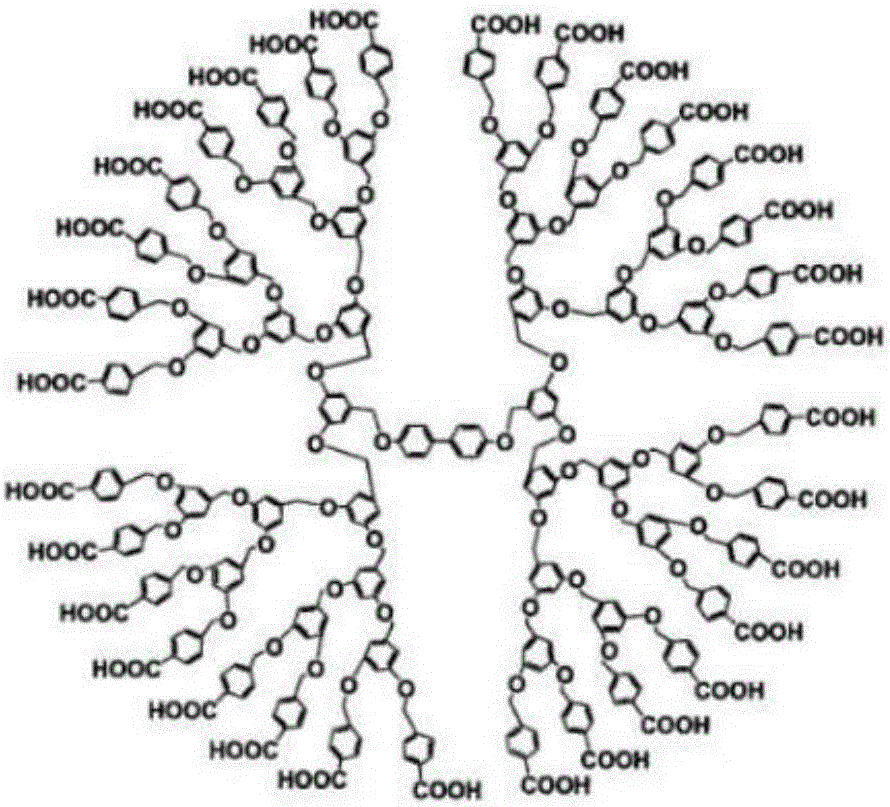

[0041] Add 79 parts by weight of deionized water into the reactor, then add 10 parts by weight of glycerin, and 5 parts by weight of polyethylene glycol 600, stir evenly, add 2 parts by weight of three-generation aryl ether dendrimers, and stir evenly.

[0042] Add 1 weight part of ethylenediamine, and stir evenly. Add 1 weight part of 1-methyl-3-methoxyimidazole chloride and 2 weight parts of imidazolidinone, and stir evenly to obtain the finished product.

Embodiment 2

[0044] A kind of air purification liquid, its formula is:

[0045]

[0046] A kind of preparation method of air purification liquid, concrete steps are:

[0047] Add 71.5 parts by weight of deionized water into the reactor, then add 1 part by weight of glycerin, 12 parts by weight of polyethylene glycol 400, and 3 parts by weight of polyethylene glycol 800, stir evenly, and then add quaternary aryl ether 0.5 parts by weight of the dendritic polymer, stirred evenly.

[0048] Add 1 weight part of ethylenediamine, and stir evenly. Add 5 parts by weight of 1-methoxy-3-methoxyimidazole chloride and 6 parts by weight of imidazolidinone, and stir evenly to obtain the finished product.

Embodiment 3

[0050] A kind of air purification liquid, its formula is:

[0051]

[0052] A kind of preparation method of air purification liquid, concrete steps are:

[0053] In the reactor, add 40.5 parts by weight of deionized water, then add 50 parts by weight of glycerin, 0.5 parts by weight of polyethylene glycol 600, and stir evenly with 0.5 parts by weight of polyethylene glycol 100, then add three generations of aryl ether dendritic 5 parts by weight of the polymer, stirred evenly.

[0054] Add 0.5 parts by weight of ethylenediamine, and stir evenly. Add 2.5 parts by weight of 1-methyl-3-methoxyimidazole nitrate and 0.5 parts by weight of imidazolidinone, and stir evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com