Green high-performance concrete water permeable brick and preparation method thereof

A high-performance concrete and permeable brick technology, applied in the field of building materials, can solve the problems of complex production process, low compressive strength, large difference in durability, etc., to save natural sand and gravel resources, reduce urban surface temperature, and improve product additional effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

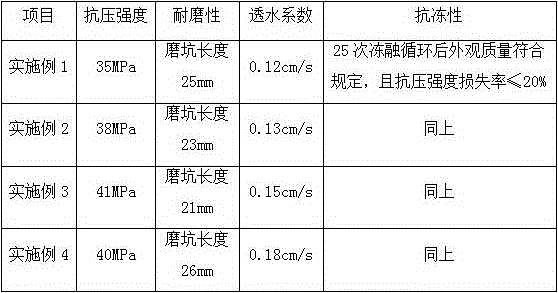

Examples

Embodiment 1

[0027] Raw materials (by weight):

[0028] 40 parts of aggregate (the aggregate is composed of granite machine-made sand and river sand, the weight ratio of granite machine-made sand and river sand is 1:1), 20 parts of sulphoaluminate cement, submerged arc furnace granulated slag powder 2 parts, 5 parts of gelling agent (triethanolamine), 0.1 part of superplasticizer, 0.1 part of dispersant.

[0029] Preparation:

[0030] S1. First, add the aggregate, submerged arc furnace granulated slag powder and appropriate amount of water into the mixer and stir evenly, then add sulphoaluminate cement, gelling agent, high-efficiency water reducer and dispersant and continue stirring for 5-10 minutes. Appropriate amount of water to adjust the consistency of the mixture, put the mixed material into the permeable brick mould, vibrate and press to solidify, and demould after 24 hours to obtain the permeable brick body;

[0031] S2. After forming, the permeable brick body should be cured by ...

Embodiment 2

[0034] 50 parts of aggregate (aggregate is composed of granite machine-made sand and river sand, the weight ratio of granite machine-made sand and river sand is 1.5:1), 24 parts of sulphoaluminate cement, submerged arc furnace granulated slag powder 3 parts, 10 parts of gelling agent (polyvinyl acetate), 1 part of superplasticizer, 0.2 parts of dispersant.

[0035] The preparation method of the above green high-performance concrete permeable brick is the same as that in Example 1.

Embodiment 3

[0037]70 parts of aggregate (the aggregate is composed of granite machine-made sand and river sand, the weight ratio of granite machine-made sand and river sand is 1.8:1), 28 parts of sulphoaluminate cement, submerged arc furnace granulated slag powder 5 parts, 12 parts of gelling agent (carboxymethyl cellulose and hydroxypropyl starch), 1.5 parts of superplasticizer, and 0.4 parts of dispersant.

[0038] The preparation method of the above green high-performance concrete permeable brick is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com