High-heat conductivity PBT composite material and preparation method thereof

A composite material, high thermal conductivity technology, applied in the field of high thermal conductivity PBT composite material and its preparation, can solve problems that have not been seen in reports, and achieve the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

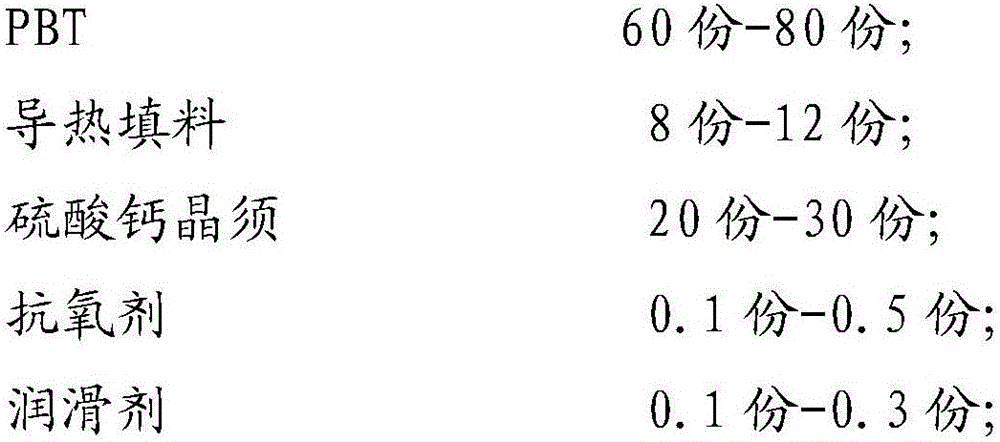

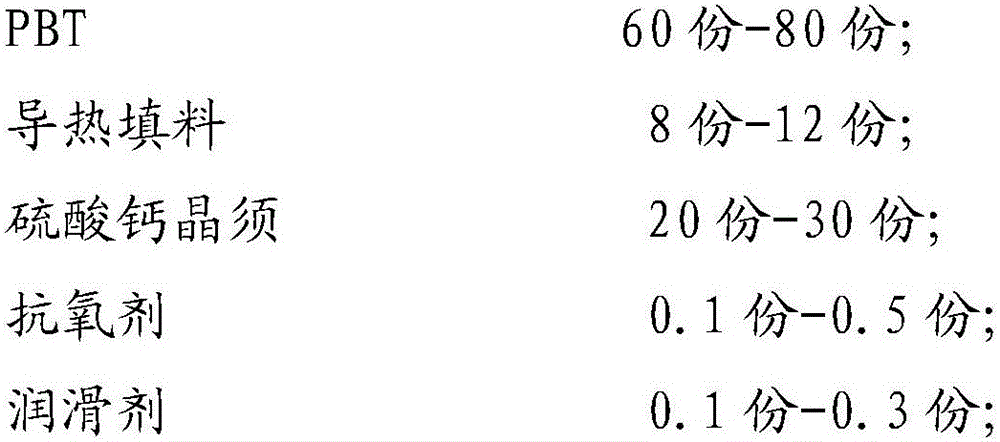

Method used

Image

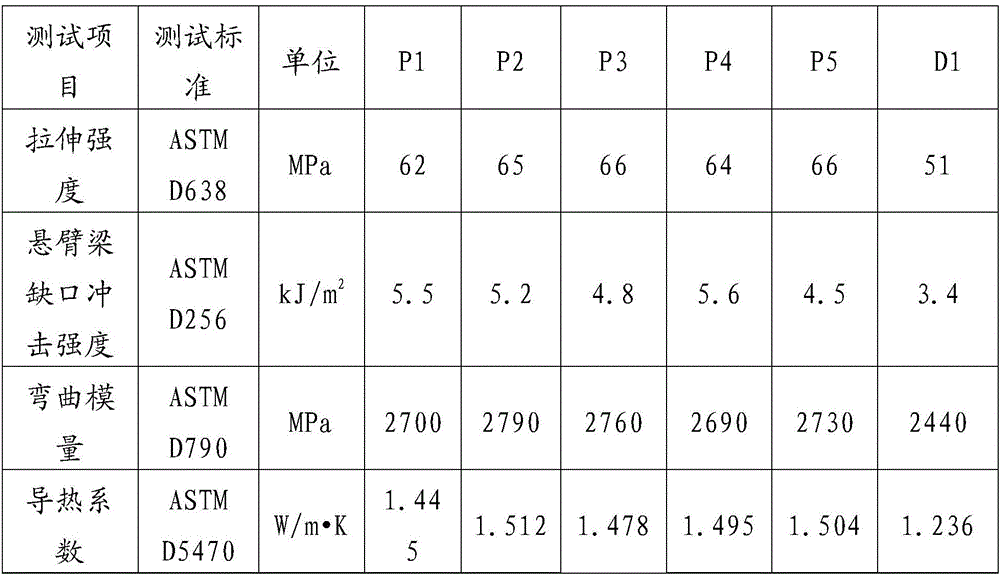

Examples

preparation example 1

[0032] The preparation method of described treated magnesia, comprises the following steps:

[0033] 1) After drying the magnesium oxide in a drying oven with a constant temperature of 100-120°C for 8-10 hours, add it to a mixer and mix for 20-30 minutes.

[0034] 2) Add the silane coupling agent KH550 into the mixer and continue mixing for 30-40 minutes.

[0035] The mass ratio of the magnesium oxide to the coupling agent is 12:1; the temperature of the mixer is 90-120° C., and the rotation speed is 120-160 r / min.

preparation example 2

[0037] The preparation method of described treated magnesia, comprises the following steps:

[0038] 1) After drying the magnesium oxide in a drying oven with a constant temperature of 100-120°C for 8-10 hours, add it to a mixer and mix for 20-30 minutes.

[0039] 2) Add the silane coupling agent KH550 into the mixer and continue mixing for 30-40 minutes.

[0040] The mass ratio of the magnesium oxide to the coupling agent is 12:3; the temperature of the mixer is 90-120° C., and the rotation speed is 120-160 r / min.

preparation example 3

[0042] The preparation method of described treated magnesia, comprises the following steps:

[0043] 1) After drying the magnesium oxide in a drying oven with a constant temperature of 100-120°C for 8-10 hours, add it to a mixer and mix for 20-30 minutes.

[0044] 2) Add the silane coupling agent KH550 into the mixer and continue mixing for 30-40 minutes.

[0045] The mass ratio of the magnesium oxide to the coupling agent is 16:1; the temperature of the mixer is 90-120° C., and the rotation speed is 120-160 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com