Marine diesel engine oil composition and application thereof

A technology for marine diesel engine and oil composition, applied in lubricating compositions, petroleum industry and other directions, can solve the problems of poor water-washing resistance of marine engine oil, achieve superior water-washing resistance, and solve the reduction rate of alkali value and sulfated ash content overly effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

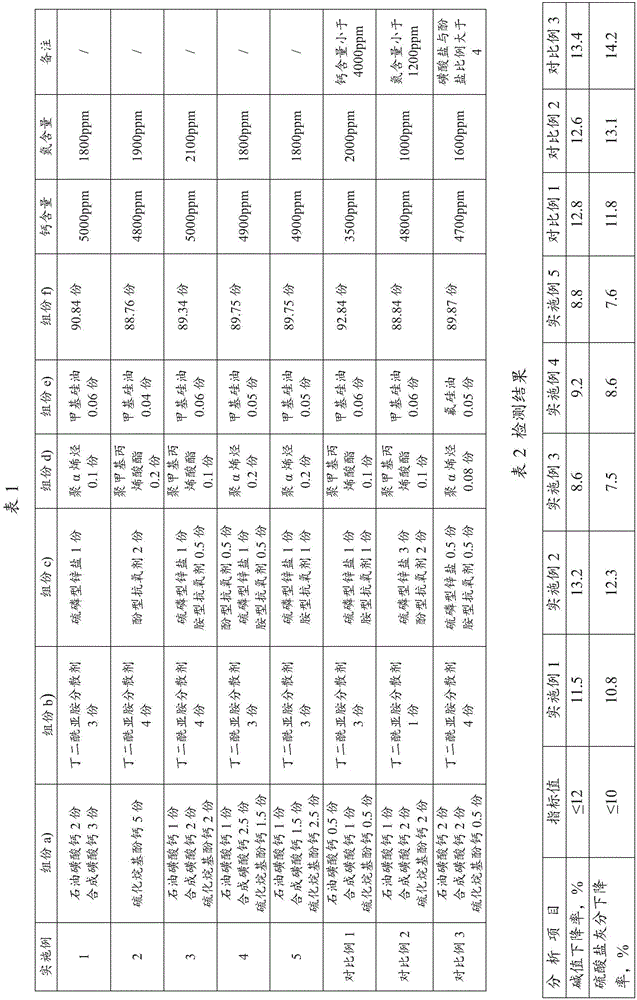

[0025] Each component of the raw material was prepared into each formulation for experimentation, and the composition of each formulation is shown in Table 1. The above mixture was heated and stirred at 60° C. for 1 hour until completely homogeneous.

[0026] The water washing resistance test (GJB 6028) was used to investigate the water washing resistance of the oil. The lower the decrease rate of alkali number and sulfate ash content, the better the water washing resistance of the oil.

[0027] The specific results of each formula test are shown in Table 2.

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com