Novel pre-cooking method for alcohol production

A pre-cooking and new method technology, applied in the direction of biofuel, fermentation, etc., can solve the problems of easy agglomeration and unfavorable liquefaction of corn particles, and achieve the effect of enhancing the extraction effect, improving the conversion rate, and increasing the yield of fermentation alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

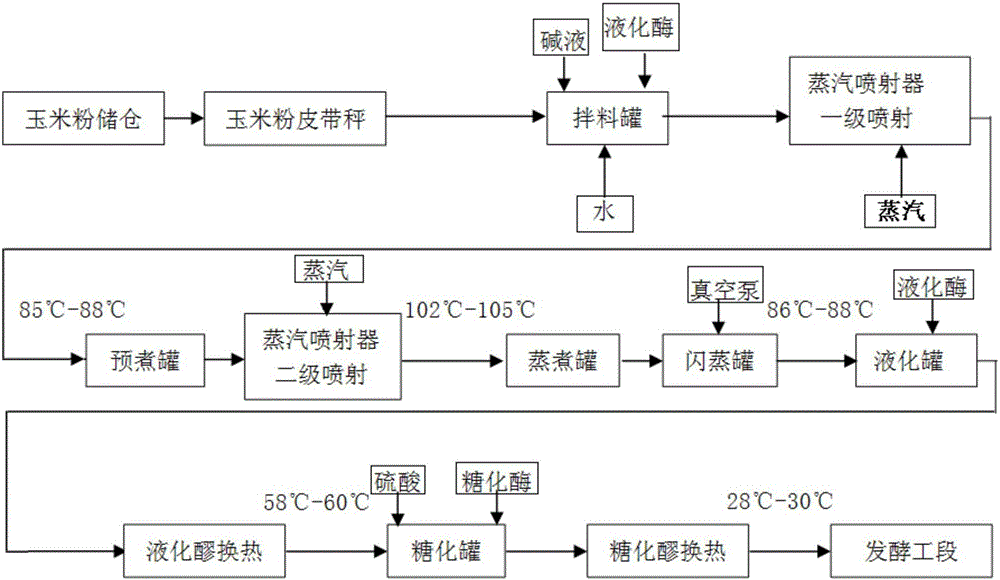

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the novel method of ethanol production precooking is characterized in that: comprise the following steps, and following steps are carried out sequentially,

[0035] Step 1. Weigh the corn flour through a belt scale and transport it to the mixing tank. Add water to the mixing tank and mix. The mass ratio of corn flour and water is 1:2.4. The corn flour and water are stirred and mixed. The volume of the slurry is 70% of the volume of the mixing tank. Add liquefying enzyme into the mixing tank through a metering pump, set the temperature of the mixing tank at 58° C., and adjust the pH value of the slurry to 5.4 with a NaOH aqueous solution with a mass concentration of 42%. The water is fresh process water mixed with evaporator condensed water;

[0036] Step 2. Transport the slurry in step 1 to the precooking tank through the slurry delivery pump. During the transportation process, the slurry is sheared and heated by the steam injector, and the working tempera...

Embodiment 2

[0045] Embodiment 2, the novel method of ethanol production precooking is characterized in that: comprise the following steps, and following steps are carried out sequentially,

[0046] Step 1. Weigh the corn flour through a belt scale and transport it to the mixing tank. Add water to the mixing tank and mix. The mass ratio of corn flour and water is 1:2.4. The corn flour and water are stirred and mixed. The slurry volume is 90% of the volume of the mixing tank. Add liquefied enzyme into the mixing tank through a metering pump, set the temperature of the mixing tank at 60°C, and adjust the pH value of the slurry to 40% NH4OH aqueous solution with a mass concentration of NH3 5.8, where water is fresh process water mixed with evaporator condensate;

[0047] Step 2. Transport the slurry in step 1 to the precooking tank through the slurry delivery pump. During the transportation process, the slurry is sheared and heated by the steam injector, and the working temperature of the ste...

Embodiment 3

[0056] Embodiment 3, the novel method of ethanol production precooking is characterized in that: comprise the following steps, and following steps are carried out sequentially,

[0057] Step 1. Weigh the corn flour through a belt scale and transport it to the mixing tank. Add water to the mixing tank and mix. The mass ratio of corn flour and water is 1:2.4. The corn flour and water are stirred and mixed. The volume of the slurry is 80% of the volume of the mixing tank. Add liquefied enzyme into the mixing tank through a metering pump, set the temperature of the mixing tank at 59°C, and adjust the pH value of the slurry to 5.6 with an aqueous NaOH solution with a mass concentration of 52%.

[0058] Step 2. Transport the slurry in step 1 to the precooking tank through the slurry delivery pump. During the transportation process, the slurry is sheared and heated by the steam injector, and the working temperature of the steam injector is set at 87°C. , the slurry after shearing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com