Leak detection and positioning method for vacuum equipment

A technology for vacuum equipment and leak detection, applied in the field of leak detection, can solve the problems of leak location technology, leak high-frequency acoustic emission signals, and the leak detection algorithm of vacuum equipment is not clearly explained, so as to achieve short detection time, high environmental adaptability, and improved safety. Coefficients and Economic Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

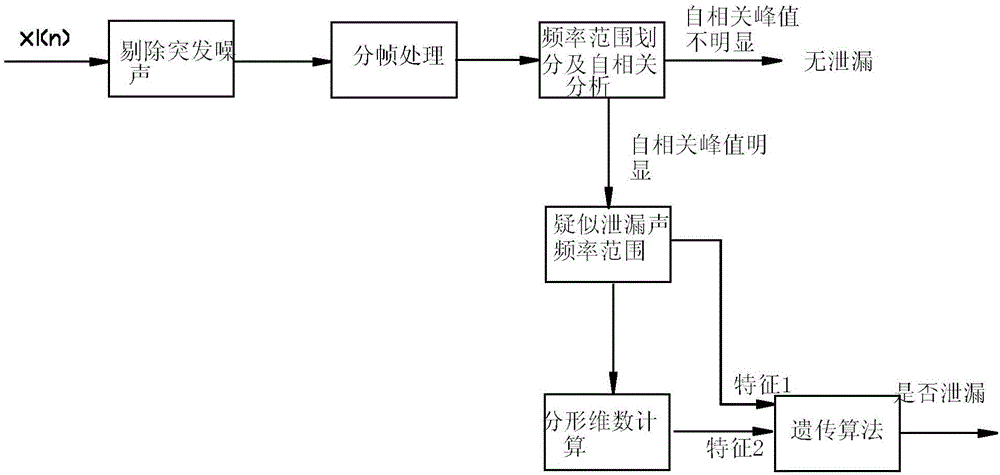

[0036] A method for detecting and locating vacuum equipment leakage. A plurality of broadband vibration sensors are preliminarily arranged on the outer surface of the vacuum equipment. circuit and A / D conversion, the vibration sensor obtains a vibration signal reflecting the current state of the vacuum equipment. The vibration signal may include the following components: 1) If there is a leak in the vacuum equipment, the vibration and sound signal caused by the leakage; 2) The vibration signal in the environment where the vacuum equipment is located, such as various pumps; 3) The circuit noise of the detection equipment Signal. In addition, there are structural differences between different vacuum equipment, which makes the leakage acoustic vibration signal itself have differences in amplitude, frequency and other characteristics, and due to the existence of various noises, it is difficult to achieve accurate detection of vacuum equipment leakage by conventional time-frequency...

Embodiment 2

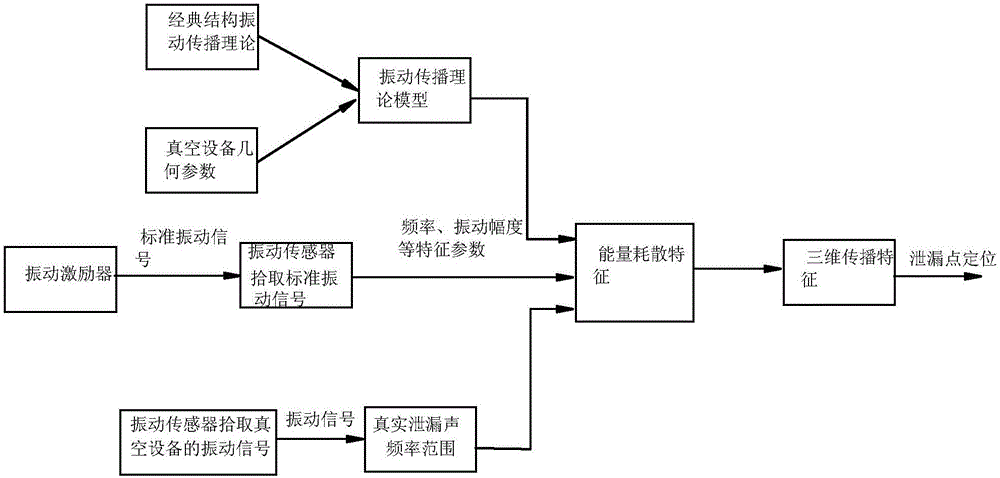

[0045] Such as figure 2 As shown, after confirming that there is a real leak in the vacuum equipment, it is necessary to locate the leak point. Due to the complex structure of vacuum equipment and the existence of branch structures, it is difficult to accurately locate the leak point by using the traditional time-delay method. Therefore, according to the structural characteristics of the vacuum equipment, combined with the actual model of vibration propagation and the energy dissipation characteristics of different positions of the vacuum equipment, the leakage can be realized. The process of point positioning is as follows:

[0046] First, establish the actual model of vibration propagation on the vacuum equipment, the specific method is as follows:

[0047] (1) According to the geometric parameters of the vacuum equipment, such as size, in combination with the classical structural vibration transmission theory, the vibration transmission theoretical model of the vacuum equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com