Optimal control for change conduction time of CRM boost PFC (Power Factor Correction) converter

A technology of on-time and optimal control, applied in the direction of high-efficiency power electronic conversion, output power conversion devices, electrical components, etc., can solve problems such as reducing computational complexity and system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

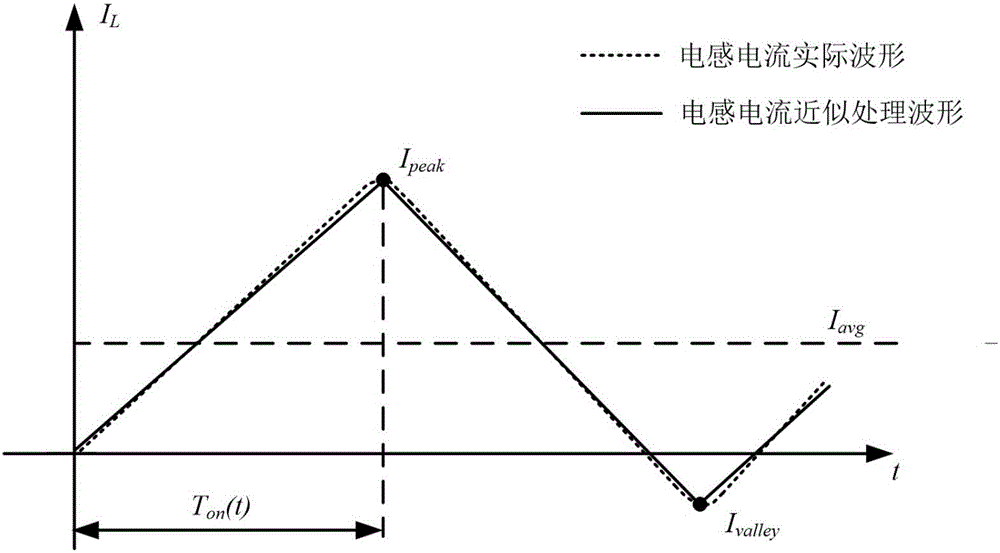

[0056] The optimal control of the change conduction time of the CRM step-up PFC converter of the present invention, under any condition within the working range of the CRM step-up PFC converter, the conduction time T of the switch tube on The operation process of (t) is consistent. Through the optimized control, the complexity of the entire control system can be reduced on the basis of reducing the input current THD of the CRM step-up PFC converter, thereby reducing the system cost. The optimal control adopted is based on the principle that the average current of the inductor in the CRM step-up PFC converter is equal to the sinusoidal reference current, and since the inductor current changes linearly in a switching cycle except for a very short resonance time, it can be The inductor current waveform is approximated as a triangle (see figure 2 ) to simplify the calculation of the average inductor current.

[0057] The optimized control of the CRM step-up PFC converter of the...

Embodiment 2

[0107] Embodiment 2: Based on the TMS320F28335 digital controller, realize the unified digital control method of the on-time operation optimization of the variable on-time control of the CRM Boost PFC converter

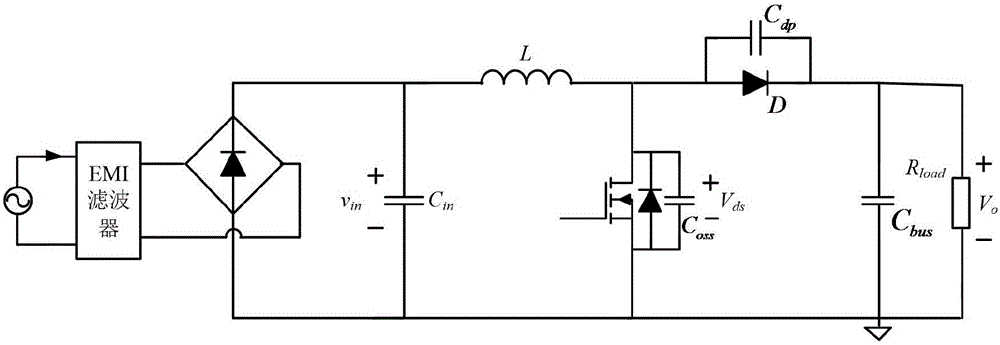

[0108] figure 1 It is the main circuit of CRM step-up PFC converter, including EMI filter, rectifier bridge, input capacitor, boost inductor, switch tube, diode, output capacitor and load. The circuit parameters of the CRM step-up PFC converter used in the example are: boost inductance L=230uH, parasitic capacitance C of the power device oss +C dp =80pF. The test conditions are: line frequency 50Hz, AC input voltage 110V and 220V, output bus voltage 400V, full load output power 200W. This example tests the input current THD against constant on-time control at 20%, 40%, 50%, 60%, 80% and 100% load respectively.

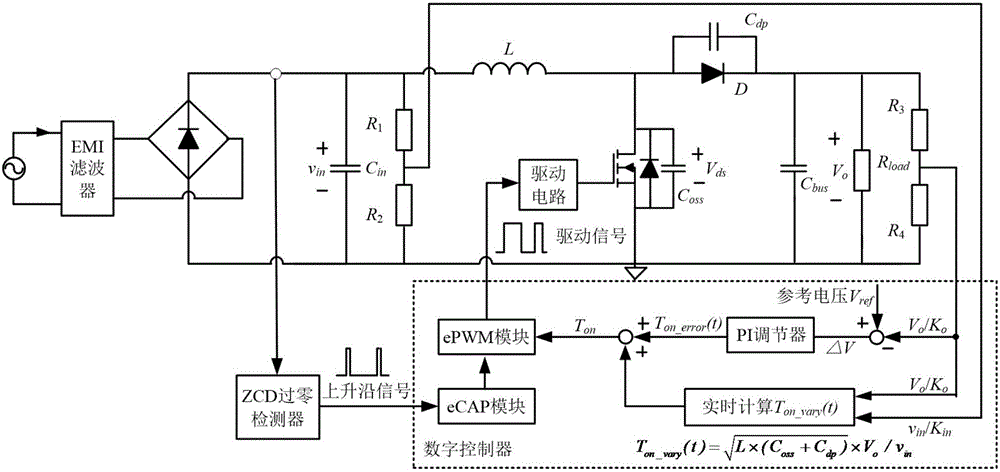

[0109] image 3 In order to realize the digital control circuit diagram of optimized unified control, in addition to the main circuit, a voltage sampling...

Embodiment 3

[0126] Embodiment 3: Realize the optimization and unification of the on-time operation of the variable on-time control of the CRM step-up PFC converter through analog circuit control

[0127] figure 1 It is the main circuit of CRM step-up PFC converter, including EMI filter, rectifier bridge, input capacitor, boost inductor, switch tube, diode, output capacitor and load. The circuit parameters of the CRM step-up PFC converter used in the example are: boost inductance L=230μH, parasitic capacitance C of the power device oss +C dp =80pF, the gain coefficient K of the multiplier M is 0.1 / V. The test conditions are: line frequency 50Hz, AC input voltage 110V and 220V, output bus voltage 400V, full load output power 200W.

[0128] Figure 5 Using the analog control method to realize the optimized and unified schematic diagram of the on-time operation of the variable on-time control of the CRM step-up PFC converter, including the voltage sampling circuit, the inductor current z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com