Dispersible oil suspending agent containing oxadiargyl and oxyfluorfen and preparation method of dispersible oil suspending agent

A technology of oxyfluorfen and oxadiazone propargyl, applied to herbicides and algicides, botanical equipment and methods, biocides, etc., can solve the problem of lack of herbicides, no guarantee of efficacy and damage, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

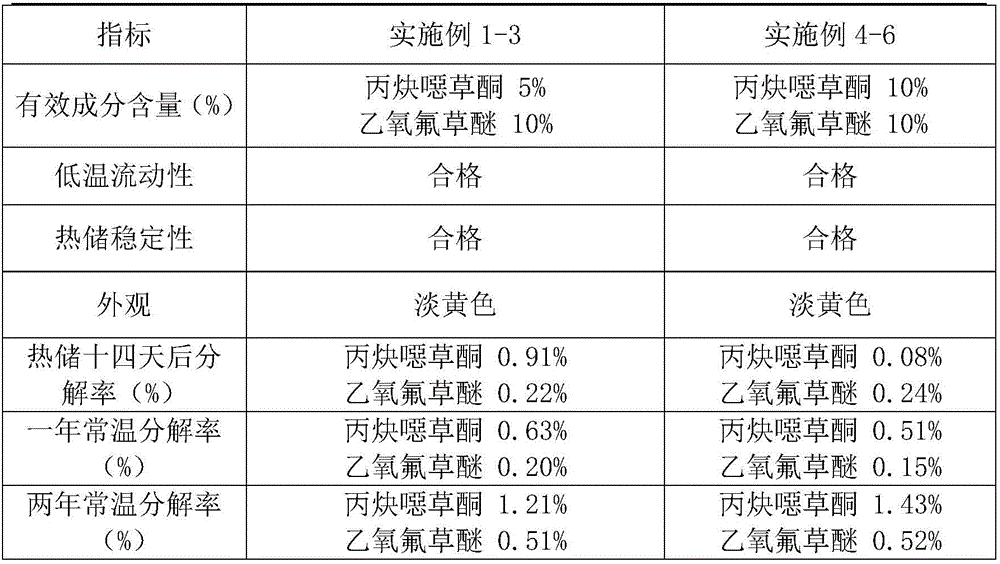

Examples

Embodiment 1

[0018] Example 1: 15% propargyl oxadiazone · oxyfluorfen dispersible oil suspension concentrate

[0019] After adding 589.3g of methyl oleate in the shear kettle, add 100g of emulsifier castor oil polyoxyethylene ether, 50g of fatty polyoxyethylene ether, 10g of dispersant naphthalenesulfonate formaldehyde condensate, 20g of white carbon black, add 52.6g 95% propargyl oxadiazone technical, 103.1g 97% oxyfluorfen technical, 50g cyclohexanone, 10g β-cyclodextrin, mixing, stirring, in a high-speed shearing machine at a speed of 1000-2000 rpm Under stirring and shearing, shear for 20-30 minutes, and then grind through a sand mill until D95 is less than 8 microns, then add 15g of thickener organic soil, and stir at a shearing machine of 1000-2000 rpm for 30-40 Minutes, D95 is measured to be less than 8 microns, that is, a pale yellow 15% oxadiazone-oxyfluorfen dispersible oil suspension concentrate is prepared, wherein the mass percentage of oxadiazone-propargyl is 5%, and oxadiazo...

Embodiment 2

[0020] Example 2: 15% propargyl oxadiazone · oxyfluorfen dispersible oil suspension concentrate

[0021] After adding soybean oil 559.3g in the shear kettle, add emulsifier polyol fatty acid ester ether 150g, nonylphenol polyoxyethylene ether 50g, dispersant lignosulfonate 20g, white carbon black 10g, add 52.6g95 % propargyl oxadiazone technical, 103.1g97% oxyfluorfen technical, 40g N,N-dimethylformamide, mixing, stirring, stirring and shearing at a speed of 1000-2000 rpm in a high-speed shearing machine Cutting, shearing for 20-30 minutes, and then grinding by a sand mill until the D95 is less than 8 microns, then adding 15g of thickener organic soil, stirring for 30-40 minutes at a speed of 1000-2000 rpm of the shearing machine, and measuring D95 is less than 8 microns, that is, a light yellow 15% oxadiazone-oxyfluorfen dispersible oil suspension concentrate is obtained, wherein the mass percentage of clomazone-propargyl is 5%, and the mass percentage of oxyfluorfen is 5%. ...

Embodiment 3

[0022] Example 3: 15% propargyl oxadiazone · oxyfluorfen dispersible oil suspension concentrate

[0023] After adding 563.3g of rosin-based vegetable oil in the shear kettle, add emulsifier nonylphenol polyoxyethylene ether 120g, castor oil polyoxyethylene ether 75g, dispersant alkylphenol polyoxyethylene ether formaldehyde condensate 16g, white carbon Black 15g, add 52.6g 95% propargyl oxadiazone technical material, 103.1g 97% oxyfluorfen technical material, 40g N,N-dimethylformamide, mix and stir, and use a high-speed shearing machine at 1000-2000 rpm Stir and shear at a speed of 10 minutes, shear for 20-30 minutes, and then grind through a sand mill until D95 is less than 8 microns, then add 15g of thickener organic soil, and stir at a speed of 1000-2000 rpm in the shearing machine After 30-40 minutes, D95 was measured to be less than 8 microns, that is, a light yellow 15% oxadiazone-ethoxyfluorfen dispersible oil suspension concentrate was prepared, wherein the oxadiazone-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com