Composite membrane filter material structure and window type draught fan system

A filter material and fan system technology, applied in ventilation systems, air conditioning systems, dispersed particle filtration, etc., can solve problems such as unacceptable cost for users, large temperature difference between morning and evening, easy condensation, etc., and achieve excellent particle filtration effect, carbon dioxide The effect of high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

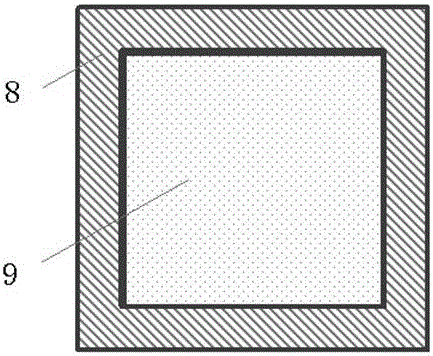

[0033] A composite membrane filter material structure, comprising a skeleton material 1 and an eFTFE membrane 2 compounded thereon (such as figure 1 shown).

[0034] Wherein, the skeleton material 1 is a mesh fabric, including mesh cloth woven from polyester, nylon, nylon, etc.;

[0035] ePTFE (microporous polytetrafluoroethylene) membrane, with an index thickness of 5 to 10 microns, and an air permeability of 80 to 120 mm / s under a pressure difference of 200 PA.

[0036] Skeleton material 1 and ePTFE membrane 2 are bonded with hot melt adhesive, and the production steps are as follows:

[0037] a. Melt the hot melt adhesive to 75 to 95°C;

[0038] b. Use a bonding machine to press and bond the skeleton material and the ePTFE membrane together;

[0039] c. Put the laminated materials in the natural air for 48 hours for curing.

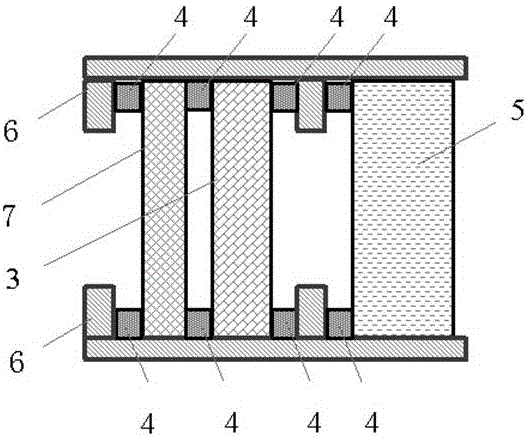

[0040] The window type fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com