Preparing method of vanadium-aluminum alloy oxygen content determination samples

A vanadium-aluminum alloy, oxygen content technology, applied in the direction of test sample preparation, sampling, measuring equipment, etc., can solve the problem that the uniformity of the vanadium-aluminum alloy sample cannot be guaranteed, and achieve the avoidance of sample oxidation, high precision, heavy weight, etc. Good performance and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of vanadium aluminum alloy oxygen content determination sample of the present invention comprises the steps:

[0016] (1) Coarse crushing: After the vanadium-aluminum alloy is roughly crushed to 5mm-20mm, select 80g-100g of fresh cross-section samples all around;

[0017] (2) Crushing: crushing for 5-10 seconds;

[0018] (3) Sieving: use 20-mesh and 80-mesh sample sieves to overlap and sieve, discard the samples on the 20-mesh sample sieve and under the 80-mesh sample sieve, and take the sample in the middle of 0.180mm ~ 0.900mm as the analysis sample.

[0019] Preferably, the crushing time described in step (2) is 5 s to 8 s for 50 AlV to 70 AlV, and 8 s to 10 s for 75 AlV to 80 AlV.

[0020] Preferably, the pulverization described in step (2) adopts a high manganese alloy steel bowl.

[0021] Preferably, the crushing time described in step (2) is 5s for both 55AlV and 65AlV, and 10s for 80AlV.

Embodiment 1

[0024] Take 500g of 55AlV alloy, (1) Coarse crushing: Coarsely crushing the vanadium-aluminum alloy to -20mm, select 100g of fresh cross-sections around 5mm to 20mm, and no oxide layer on the surface; (2) Crushing: In high manganese alloy steel Crush in the material bowl for 5 seconds; (3) Sieve: use 20-mesh and 80-mesh sample sieves to overlap and sieve, discard the samples on the 20-mesh sample sieve and the sample under the 80-mesh sample sieve, and obtain the intermediate sample with a particle size of 0.180-0.900mm. As the analysis sample, the oxygen content in vanadium aluminum alloy was determined by pulse-inert gas melting method.

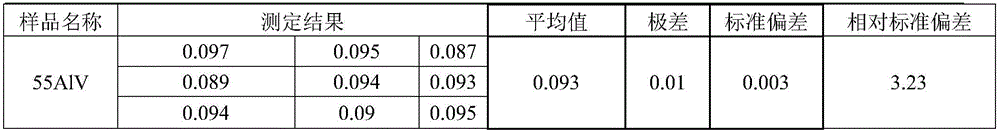

[0025] The test of the above-mentioned Example 1 was repeated 9 times, and the results of the oxygen content are shown in Table 1.

[0026] Table 1 Example 1 Oxygen content / wt%

[0027]

Embodiment 2

[0029] Take 400g of 65AlV alloy, (1) Coarsely crushing: Coarsely crush the vanadium-aluminum alloy to -20mm, select 5mm to 20mm and 80g of fresh cross-sections around it, with no oxide layer on the surface; (2) Crushing: In high manganese alloy steel Crush in the material bowl for 5 seconds; (3) Sieve: use 20-mesh and 80-mesh sample sieves to overlap and sieve, discard the samples on the 20-mesh sample sieve and the sample under the 80-mesh sample sieve, and obtain the intermediate sample with a particle size of 0.180-0.900mm. As the analysis sample, the oxygen content in vanadium aluminum alloy was determined by pulse-inert gas melting method.

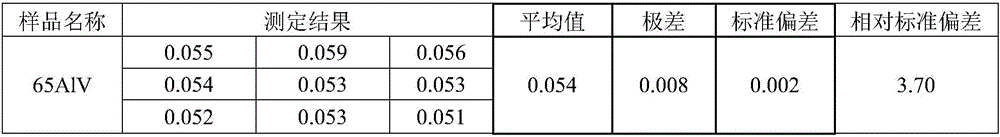

[0030] The test of the above-mentioned Example 2 was repeated 9 times, and the results of the oxygen content are shown in Table 2.

[0031] Table 2 Example 2 Oxygen content / wt%

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com