A kind of pasty magnesium-zinc composite heat stabilizer for polyvinyl chloride

A technology of compounding heat stabilizer and polyvinyl chloride, applied in the chemical industry, can solve problems such as poor thermal stability, and achieve the effects of maintaining fluidity, easy operation cost, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Weigh 200 kg of zinc p-tert-butylbenzoate, 100 kg of β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, 6-amino-1,3-dimethyl 200 kilograms of base uracil and 400 kilograms of magnesium hydroxide were pulverized to 2-5 microns through a jet mill, and they were called group A for use. In the conical mixer of 3 cubic meters, drop into 600 kilograms of epoxidized soybean oil, 400 kilograms of phosphorous acid 4,4-diisofurylidene bisphenol (12-14) carbon alkyl esters, drop into 20 kilograms of organic montmorillonites under stirring, 80 kg of triethanolamine monooleate was stirred at normal temperature and pressure for 30 minutes. Add the treated Group A, and stir for 60 minutes at normal temperature and pressure. Among them, there are low-speed agitator and high-speed agitator in the cone mixer. Low speed stirring speed: 50 rpm, high speed stirring speed: 500 rpm. Inspection, packing and warehousing.

[0024] test:

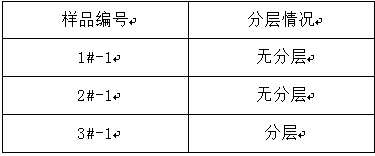

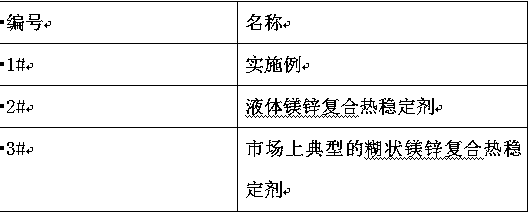

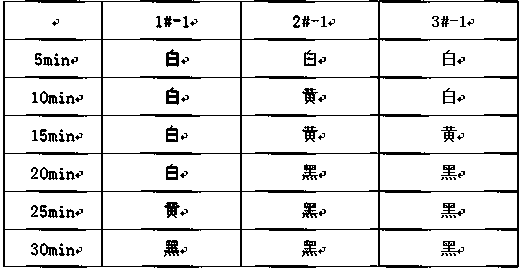

[0025] Heat stabilizer samples:

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com