Apparatus and method for surface micro/nanometer carbonization modification of fly ash

A fly ash and nano-scale technology, which is applied in chemical instruments and methods, inorganic compound addition, inorganic pigment treatment, etc., can solve the problem that the material performance cannot meet the expected goals, cannot meet the needs of multiphase reactions, and the particle size range is not limited. Control and other issues, to achieve the effect of rapid reaction and easy control, increase the rate of carbonization reaction, and promote dissolution and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Feeding and dispersion stage:

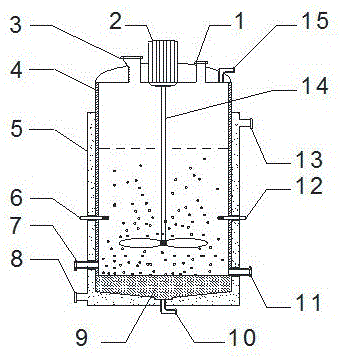

[0036] ① Start the drive motor 2 to drive the agitator 14 to run at a speed of 400rpm.

[0037] ② Then add lime milk with a mass concentration of 5% through the lime milk feed port 1, and mix evenly; 5% of the total mass of the suspension.

[0038] ③ Fully mix for 5 minutes until the fly ash solid particles in the suspension are completely dispersed.

[0039] (2) Carbonization modification stage:

[0040] ① Open the cooling water inlet 8, wait until the cooling water fills the entire insulation interlayer 5 and flows out from the cooling water outlet 13.

[0041] ② Then open the flow control valve on the inlet port 10 of the carbonized gas, and gradually adjust the flow so that the diameter of the bubbles generated after passing through the gas diffuser 9 is 1 mm. Introduce pure carbon dioxide. undissolved CO 2 It is discharged from the exhaust port 15 above the reaction tank 4 and reused when necessary.

[0042] ③ During the c...

Embodiment 2

[0046] (1) Feeding and dispersion stage:

[0047] ① Start the drive motor 2 to drive the agitator 14 to run at 400 rpm.

[0048] ② Add lime milk with a mass concentration of 7% through the lime milk feed port 1; then add fly ash powder with a particle size of 300 mesh to 400 mesh through the unmodified powder feed port 3, and its mass accounts for the reaction system suspension. 5% of the total mass.

[0049] ③ Fully mix for 5 minutes until the fly ash solid particles in the suspension are completely dispersed.

[0050] (2) Carbonization modification stage:

[0051] ① Open the cooling water inlet 8, wait until the cooling water fills the entire insulation interlayer 5 and flows out from the cooling water outlet 13.

[0052] ② Then open the flow control valve on the inlet port 10 of the carbonized gas, and gradually adjust the flow so that the diameter of the bubbles generated after passing through the gas diffuser 9 is 1 mm. And adjust the volume content of air in the carb...

Embodiment 3

[0057] (1) Feeding and dispersion stage:

[0058] ① Start the drive motor 2 to drive the agitator 14 to run at a speed of 600 rpm.

[0059] ② Add lime milk with a mass concentration of 10% through lime milk inlet 1; then add fly ash powder with a particle size of 400 mesh to 500 mesh through unmodified powder inlet 3, and its mass accounts for 10% of the reaction system suspension. 5% of the total mass. Add borax through cleaning water inlet 7, and the addition amount is 0.1% of the dry weight of fly ash.

[0060] ③ Fully mix for 5 minutes until the fly ash solid particles in the suspension are completely dispersed.

[0061] (2) Carbonization modification stage:

[0062] ① Open the cooling water inlet 8, wait until the cooling water fills the entire insulation interlayer 5 and flows out from the cooling water outlet 13.

[0063] ② Then open the flow control valve on the inlet port 10 of the carbonized gas, and gradually adjust the flow so that the diameter of the bubbles g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com