Well cementation material, well cementation material system and preparation method thereof

A cementing and system technology, applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problems such as strength decline of cementing hardened body, achieve low strength decline rate and permeability, not easy to settle, and reduce strength decline. The effect of rate and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

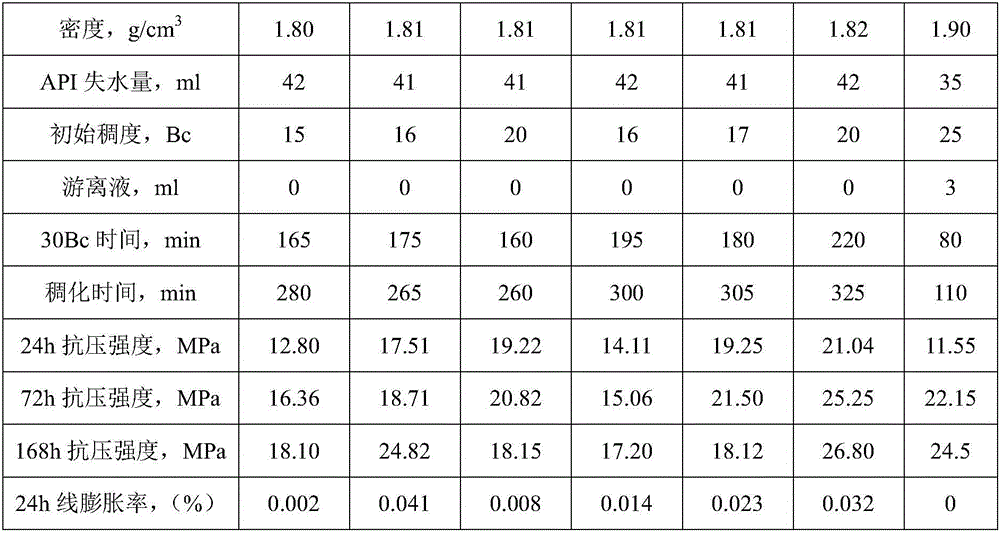

Embodiment 1

[0028] The cementing material of this embodiment is composed of the following components in parts by weight: 100 parts of high temperature resistant cementing matrix material, 5 parts of high temperature microcrystalline reinforcement material, 1.6 parts of fluid loss reducer, and 2 parts of silica fume. Mix high temperature resistant cementing matrix material, high temperature microcrystalline reinforcement material, fluid loss reducer, and silica fume evenly to obtain the product.

[0029] The cementing material system of this embodiment is composed of the following components in parts by weight: 100 parts of high temperature resistant cementing matrix material, 5 parts of high temperature microcrystalline reinforcement material, 1.6 parts of fluid loss reducer, 2 parts of silica fume, drag reducing 1.5 parts of agent, 0.2 parts of defoamer, 50 parts of water. The defoamer is tributyl phosphate.

[0030] The preparation method of the cementing material system of the present...

Embodiment 2

[0034] The cementing material of this embodiment is composed of the following components in parts by weight: 100 parts of high temperature resistant cementing matrix material, 7 parts of high temperature microcrystalline reinforcement material, 1.6 parts of fluid loss reducer, and 2 parts of silica fume. Mix high temperature resistant cementing matrix material, high temperature microcrystalline reinforcement material, fluid loss reducer, and silica fume evenly to obtain the product.

[0035] The cementing material system of this embodiment is composed of the following components in parts by weight: 100 parts of high temperature resistant cementing matrix material, 7 parts of high temperature microcrystalline reinforcement material, 1.6 parts of fluid loss reducer, 2 parts of silica fume, drag reducing 2 parts of agent, 0.2 parts of defoamer, 50 parts of water. The defoamer is tributyl phosphate.

[0036] The preparation method of the cementing material system of the present e...

Embodiment 3

[0040] The cementing material of this embodiment is composed of the following components in parts by weight: 100 parts of high temperature resistant cementing matrix material, 9 parts of high temperature microcrystalline reinforcement material, 1.6 parts of fluid loss reducer, and 2 parts of silica fume. Mix high temperature resistant cementing matrix material, high temperature microcrystalline reinforcement material, fluid loss reducer, and silica fume evenly to obtain the product.

[0041] The cementing material system of this embodiment is composed of the following components in parts by weight: 100 parts of high temperature resistant cementing matrix material, 9 parts of high temperature microcrystalline reinforcement material, 1.6 parts of fluid loss reducer, 2 parts of silica fume, drag reducing 2 parts of agent, 0.2 parts of defoamer, 50 parts of water. The defoamer is tributyl phosphate.

[0042] The preparation method of the cementing material system of the present e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com