A kind of carbon dioxide crystal film on the surface of activated carbon fiber and its preparation method

A technology of activated carbon fiber and crystal, which is applied to the YBO3 crystal film on the surface of activated carbon fiber and the field of its preparation, and achieves the effects of adjustable size, good binding force and adjustable density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 0.0575g of yttrium nitrate hexahydrate and 0.0093g of boric acid in 15.0mL of deionized water. The molar concentrations of yttrium ions and borate ions in the solution are both 0.01 mol / liter; The concentration is 0.05 mol / liter, which is equal to 5 times the molar number of yttrium ions; stir until the reactants are completely dissolved; immerse the activated carbon fibers in the above solution for 10 hours. The final solution together with the activated carbon fiber was hydrothermally treated at 85°C for 24 hours, and then heated to 210°C and kept for 12 hours; Surface YBO 3 crystal film.

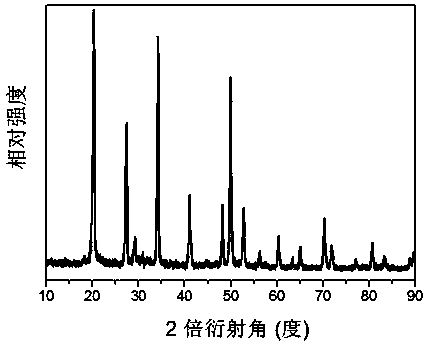

[0026] figure 1 Be the XRD collection of illustrative plates of embodiment 1 product, the characteristic diffraction peak of crystalline material and YBO on this collection of collections 3 The standard XRD pattern (JCPDS No 16-0277) matches, indicating that the crystal structure of the crystalline product is consistent with that of YBO 3 Same, is a single pure phase. ...

Embodiment 2

[0028] 0.1149g of yttrium nitrate hexahydrate and 0.0185g of boric acid were dissolved in 15.0mL of deionized water, and the molar concentration of yttrium ion and borate ion in the solution was 0.02 mol / liter; The concentration is 0.05 mmol / L, which is equal to 2.5 times the number of moles of yttrium ions; stir until the reactants are completely dissolved; immerse the activated carbon fibers in the above solution for 10 hours. The final solution together with the activated carbon fibers was hydrothermally treated at 90°C for 20 hours, then heated to 210°C and kept for 12 hours; after the reaction, the reaction kettle was naturally cooled to room temperature, the activated carbon fibers were taken out, cleaned and dried to obtain Surface YBO 3 crystal film.

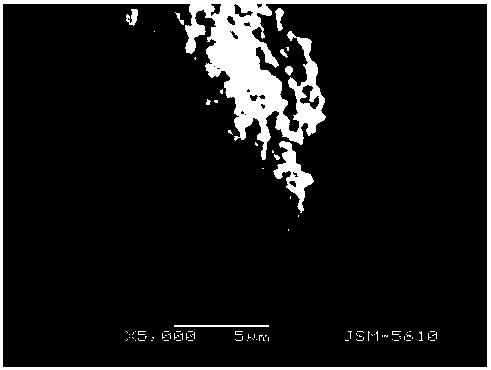

[0029] image 3 It is the SEM photograph of the product of embodiment 2, the spherical YBO coated on the activated carbon fiber surface 3 The crystal grains have a diameter of 200 nanometers to 500 nanometers.

Embodiment 3

[0031] Dissolve 0.1436g of yttrium nitrate hexahydrate and 0.0232g of boric acid in 15.0mL of deionized water. The molar concentration of yttrium ions and borate ions in the solution is 0.025 mol / liter; It is 0.1 mole / liter, which is equal to 4 times the number of moles of yttrium ions; stir until the reactant is completely dissolved; immerse the activated carbon fiber in the above solution for 10 hours. The final solution together with the activated carbon fiber was hydrothermally treated at 100°C for 12 hours, then the temperature was raised to 210°C and kept for 12 hours; after the reaction, the reaction kettle was naturally cooled to room temperature, the activated carbon fiber was taken out, cleaned and dried to obtain Surface spherical YBO 3 crystal film.

[0032] Figure 4 It is the SEM photograph of the product of embodiment 3, the spherical YBO coated on the activated carbon fiber surface 3The crystal grains have a diameter of 400 nanometers to 700 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com