Processing method of asphalt carbon fibers

A technology of pitch carbon fiber and processing method, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of low yield of mesophase, complicated technology and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A kind of processing method of pitch carbon fiber of present embodiment, comprises the steps:

[0015] (1) Add 5% of 3,4,9,10-perylenetetracarboxylic dianhydride, 5% of 2,6-naphthalene dicarboxylic acid and 5% of alkylphenyl polycarbonate to base pitch under the protection of inert gas atmosphere. Siloxane, control the temperature (350 ~ 430 ℃) for heat treatment.

[0016] (2) After the mesophase pitch is spun, the obtained pitch yarn is heat-treated (in an aqueous solution of hydrogen peroxide, sulfuric acid, and nitric acid) at a temperature of 340° C. for 30 minutes.

[0017] (3) Carry out carbonization and graphitization treatment in the mesophase pitch fiber in an inert atmosphere, the carbonization temperature is 1100°C and the carbonization time is 45 minutes; the graphitization temperature is 2300°C and the graphitization time is 15 minutes.

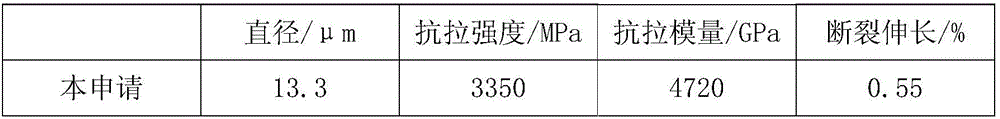

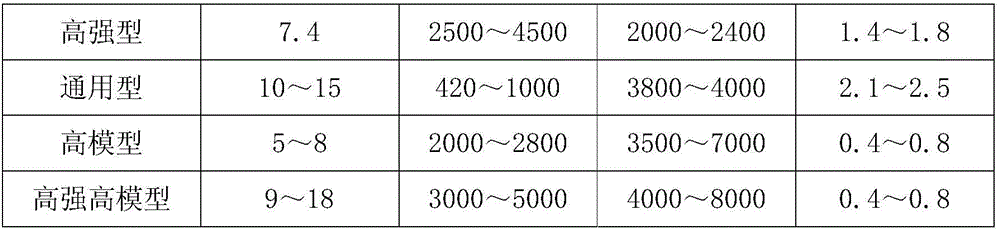

[0018] The mechanical properties of pitch carbon fibers prepared by the above process are shown in Table 1.

[0019] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com