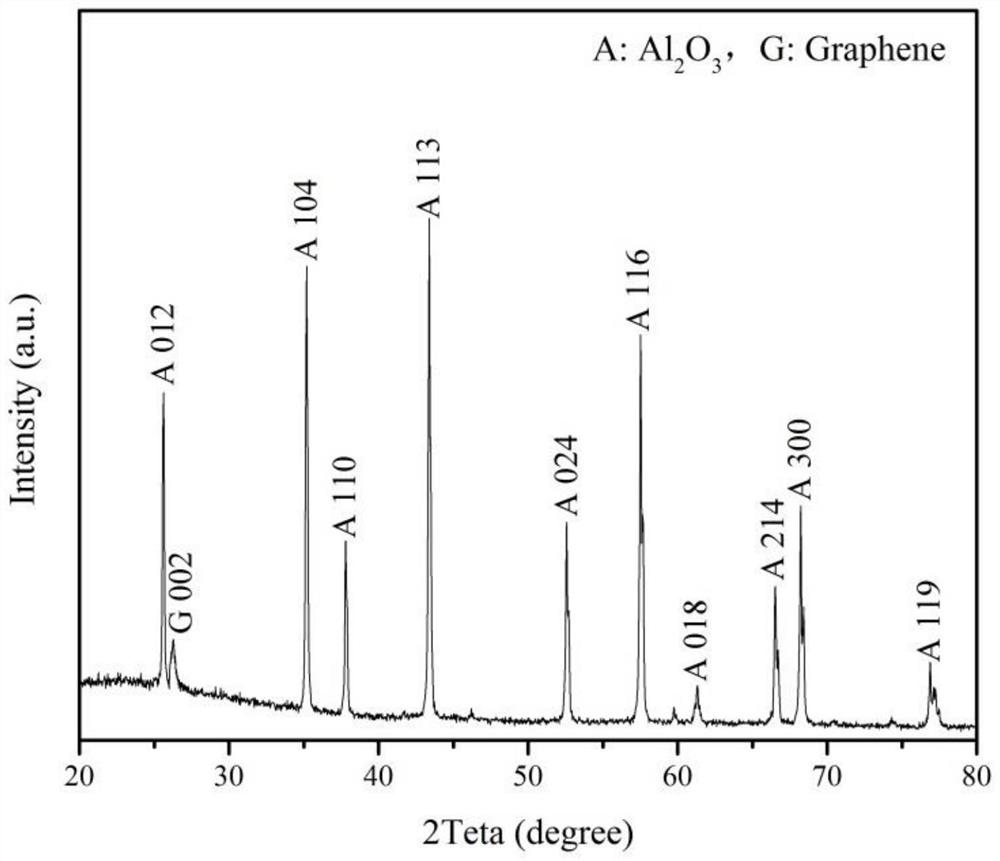

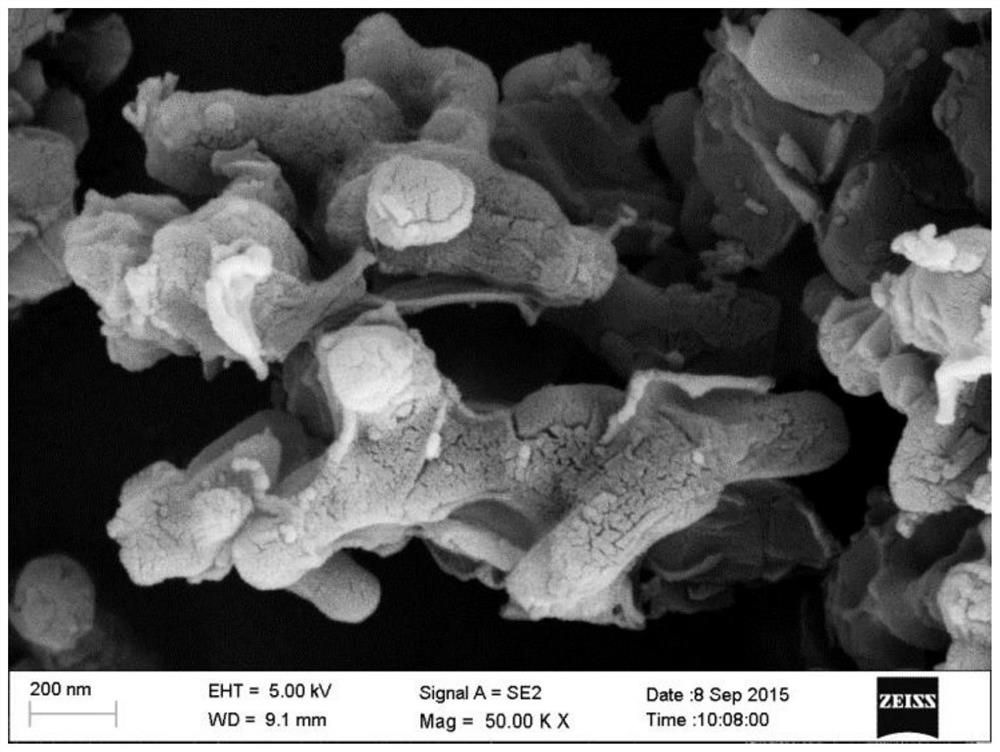

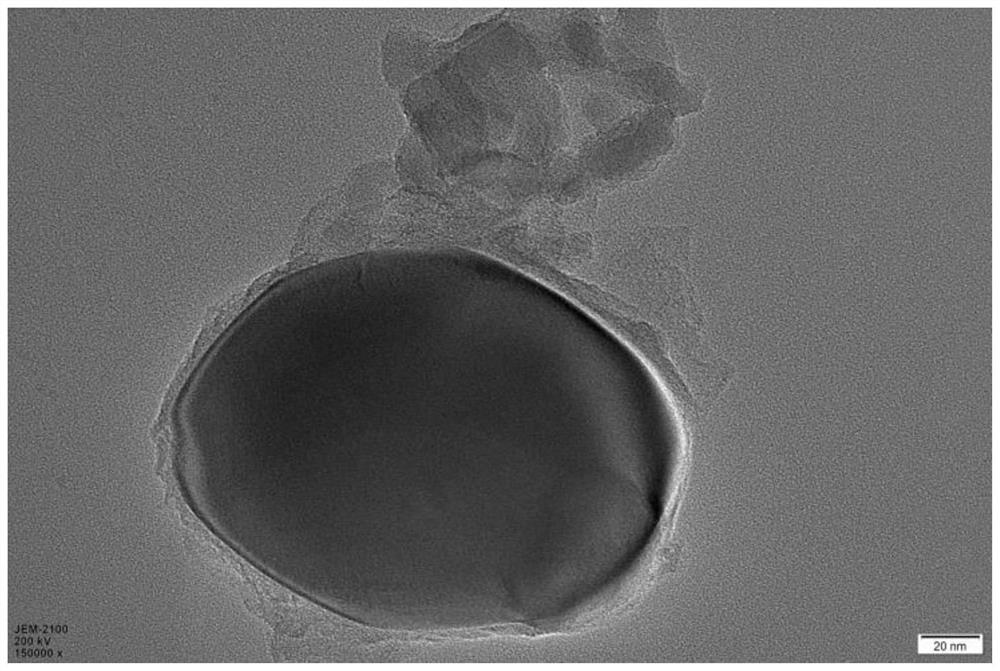

Core-shell type nano ceramic powder based on graphene coating and preparation method of core-shell type nano ceramic powder

A nano-ceramic powder, graphene coating technology, applied in the direction of graphene, nano-carbon, chemical instruments and methods, etc., can solve the problems of reducing the reinforcement effect of the ceramic matrix, the difficulty of dispersion, the difficulty of the complete structure of graphene, etc. Dispersion effect, good dispersibility, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Under the condition of room temperature water bath, 2.5mmol perylene-3,4,9,10-tetracarboxylic dianhydride and 40ml toluene were mixed for ultrasonic treatment for 15min, then 0.25mmol triethylenetetramine was added, and the reaction was refluxed at 55°C for 25h, After the reaction was completed, it was cooled to room temperature, and the reaction solution was filtered. The precipitate obtained by filtration was washed with toluene and ethanol, dried and added to a potassium hydroxide solution with a concentration of 10 wt %. The precipitate is washed with deionized water, the washed precipitate is dissolved in formic acid after vacuum drying, and excess isopropanol is added for precipitation treatment, and the polyamino cationic peryleneimide graphene dispersant is prepared after the precipitate is vacuum-dried;

[0034] (2) Mixing and stirring the above prepared polyamino cationic peryleneimide graphene dispersant and deionized water, then adding graphene, under the...

Embodiment 2

[0039] (1) Under the condition of water bath at room temperature, 2.5mmol of perylene-3,4,9,10-tetracarboxylic dianhydride and 40ml of toluene were mixed for ultrasonic treatment for 15min, then 0.2mmol of diethylenediamine was added, and the reaction was refluxed at 50°C for 25h. After the reaction was completed, it was cooled to room temperature, and the reaction solution was filtered. The precipitate obtained by filtration was washed with toluene and ethanol, dried and added to a potassium hydroxide solution with a concentration of 10 wt %. The precipitate is washed with deionized water, the washed precipitate is dissolved in formic acid after vacuum drying, and excess isopropanol is added for precipitation treatment, and the polyamino cationic peryleneimide graphene dispersant is prepared after the precipitate is vacuum-dried;

[0040] (2) Mix and stir the polyamino cationic peryleneimide graphene dispersant prepared above with deionized water, then add graphene, and under ...

Embodiment 3

[0044] (1) Under the condition of water bath at room temperature, 2.5mmol perylene-3,4,9,10-tetracarboxylic dianhydride and 40ml toluene were mixed for ultrasonic treatment for 15min, then 0.25mmol tetraethylenepentamine was added, and the reaction was refluxed at 50°C for 24h, After the reaction was completed, it was cooled to room temperature, and the reaction solution was filtered. The precipitate obtained by filtration was washed with toluene and ethanol, dried and added to a potassium hydroxide solution with a concentration of 10 wt %. The precipitate is washed with deionized water, the washed precipitate is dissolved in formic acid after vacuum drying, and excess isopropanol is added for precipitation treatment, and the polyamino cationic peryleneimide graphene dispersant is prepared after the precipitate is vacuum-dried;

[0045] (2) Mix and stir the polyamino cationic peryleneimide graphene dispersant prepared above with deionized water, then add graphene, and under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com