Leak detection method for metal corrugated oil conservator

A corrugated, oil conservator technology, used in fluid tightness testing, machine/structural component testing, and by detecting the presence of fluid at the leak point, etc., can solve problems such as time-consuming, aging of insulating oil, and discharge, etc. Achieving the effect of good safety performance and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

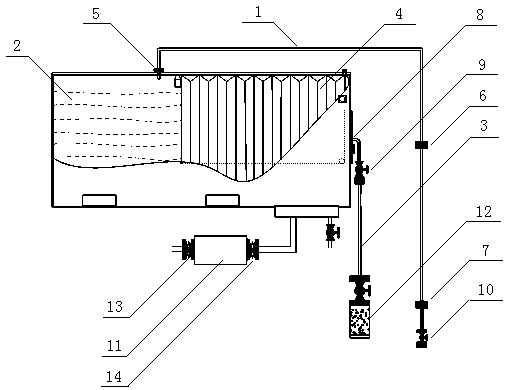

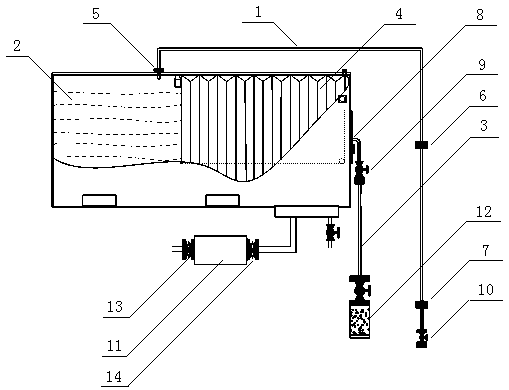

[0026] Implementation case: The gas content in the oil of a 500kV shunt high-voltage reactor increases abnormally. The equipment uses a metal corrugated oil conservator, and its structure is as follows figure 1 As shown, no oil leakage was found in the visual inspection, and it is judged that there may be a leak point in the oil conservator of the equipment.

[0027] 1. After the equipment is powered off, close the valves 13 and 14 at both ends of the gas relay 11, close the valve 9 of the respirator manifold 3, open the valve 10 of the exhaust manifold 1, and turn off the valve 10 of the exhaust manifold 1 to Inject 45 liters of sulfur hexafluoride gas with a purity of 99.99% into the oil chamber 2 of the oil conservator as a leak detection gas, then inject nitrogen gas until the relative pressure of the gas in the oil chamber 2 reaches 10kPa, and close the valve 10 of the exhaust manifold 1 ;

[0028] 2. Wrap the flanges 5, 6, 7 of the exhaust manifold 1 and the flange 8 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com