Method for acquiring mobility parameter of re-crystallized structure evolution crystal boundary of metal material

A technology of recrystallization structure and metal materials, which is applied in the analysis of materials, material analysis through optical means, material analysis using wave/particle radiation, etc., can solve the problems that cannot be directly measured through experiments, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

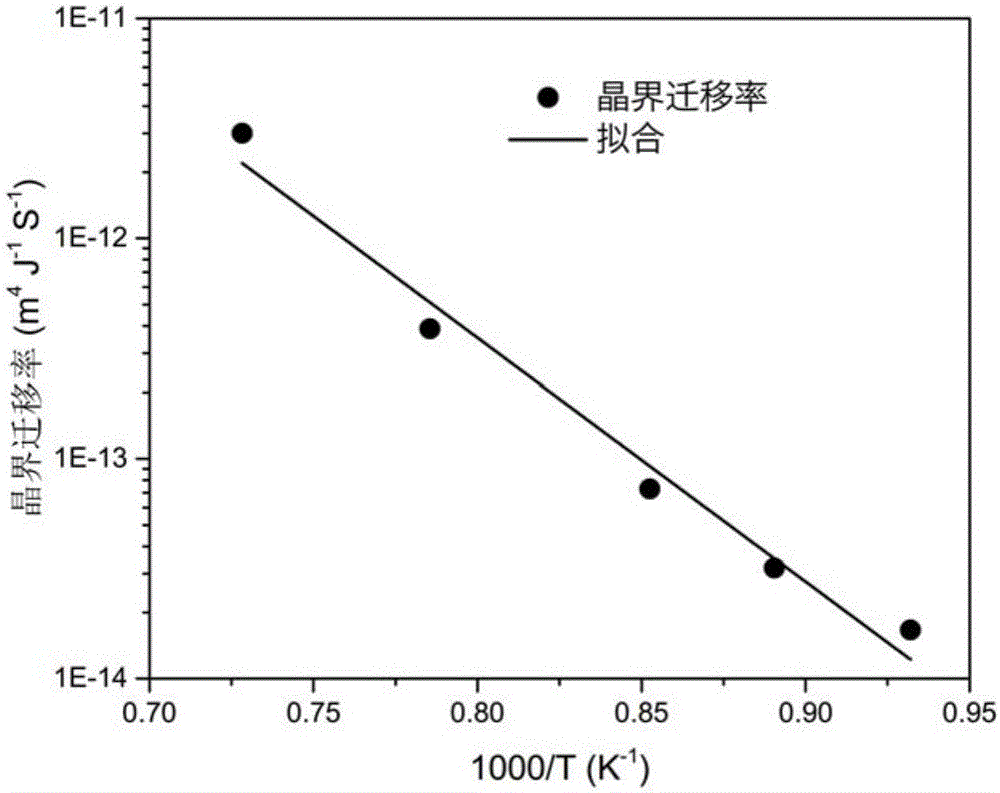

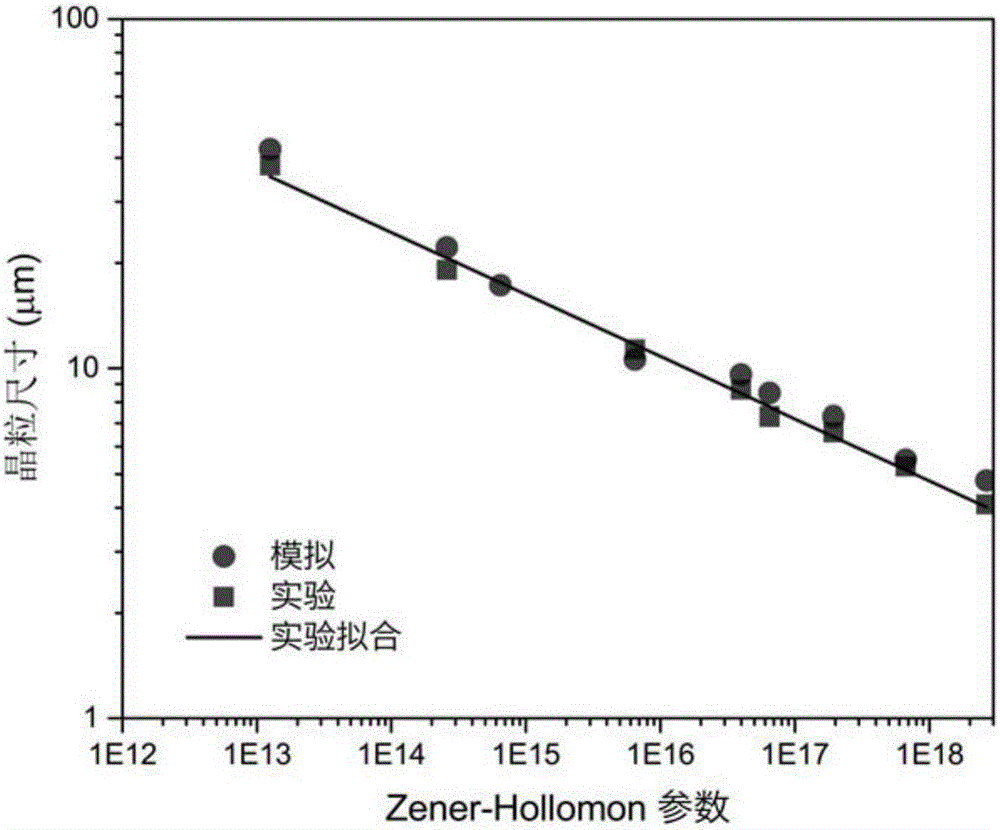

[0037] The method for obtaining the mobility parameter of the grain boundary of the recrystallization structure evolution of the metal material is characterized in that the steps of the method are as follows:

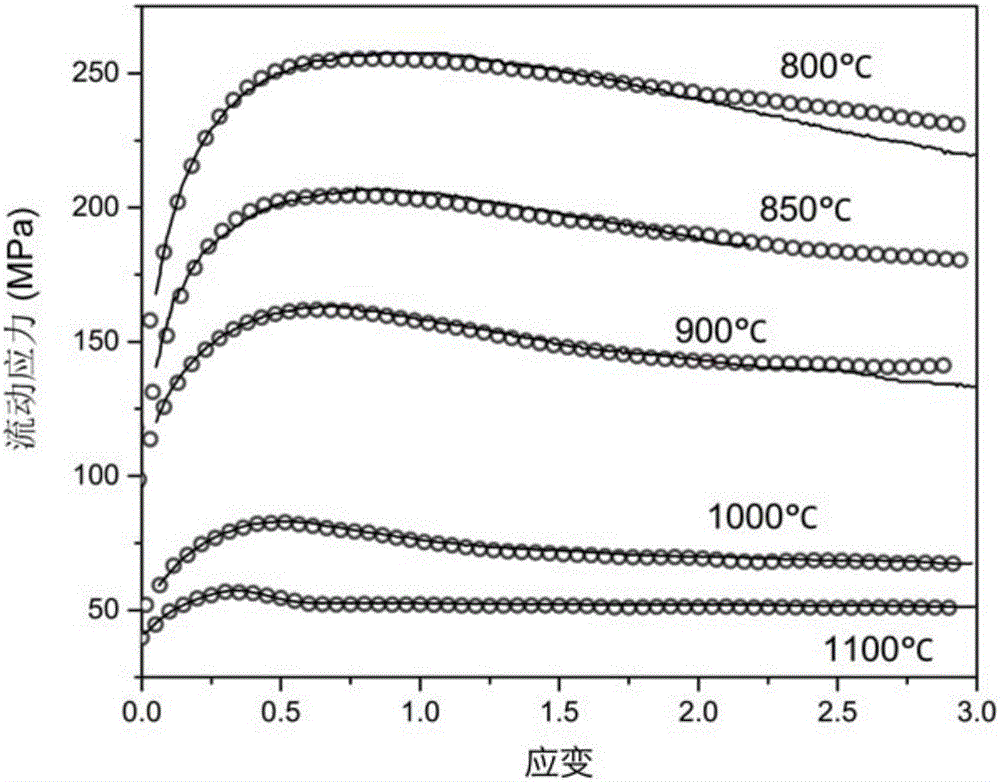

[0038] Step 1: Physical and thermal simulation experiment of dynamic recrystallization of 304L austenitic stainless steel

[0039] First measure the initial average grain size of the sample before deformation, and the initial grain size is 35 μm. Then five sets of samples were prepared, and the Gleeble thermal simulator was used for plane compression experiments. The deformation rate was 0.01 / s, and the deformation temperatures were 800°C, 850°C, 900°C, 1000°C, and 1100°C. Observe the records recorded by the Gleeble thermal simulator Stress-strain curve, when the stress-strain curve reaches the recrystallization steady-state stress value, the deformation is terminated, and the maximum deformation amount is 90% at this time;

[0040] Step 2: Use the microstructure charact...

Embodiment 2

[0059] The method for obtaining the mobility parameter of the grain boundary of the recrystallization structure evolution of the metal material is characterized in that the steps of the method are as follows:

[0060] Step 1: Physical and thermal simulation experiment of static recrystallization of pure copper

[0061] First measure the initial average grain size of the sample before deformation, and the initial grain size is 80 μm. Then use the Gleeble thermal simulator to carry out the plane compression test, the deformation amount is 50%, the annealing temperature is 500°C, 650°C, 700°C, 750°C, 800°C, and the annealing time is 300 seconds.

[0062] Step 2: Use the microstructure characterization experiment to obtain the average grain size of the static recrystallization of the sample

[0063] EBSD scanning electron microscopy is used to count the grain size of the sample, the recrystallization fraction of the sample reaches 100% to avoid the interference of non-recrystalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com