Low-carbon silicon controlled rectifier type environmentally friendly charger

A charger and environmental protection technology, applied in the electronic field, can solve the problems of the charging tube being fragile, damaged, increasing the overall scrapping of the charger, etc., and achieve the effect of streamlining the circuit and reducing the power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

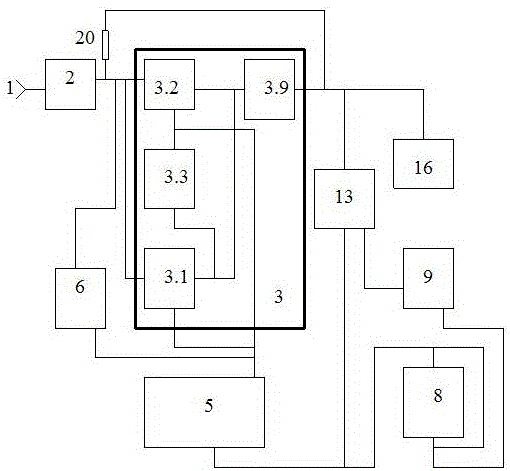

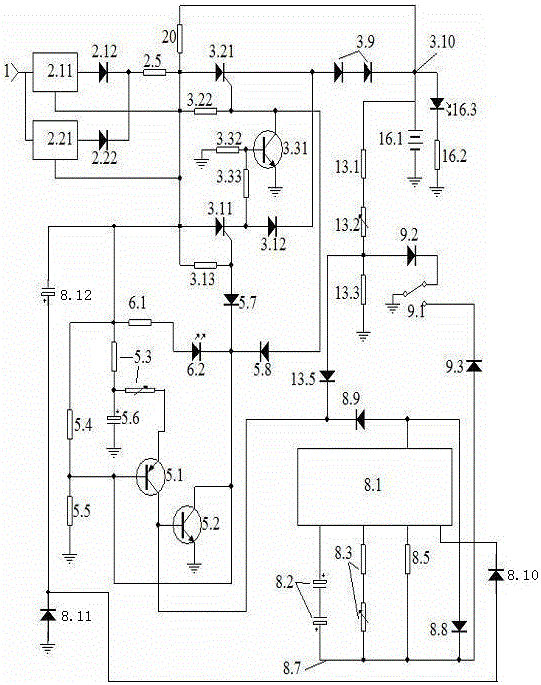

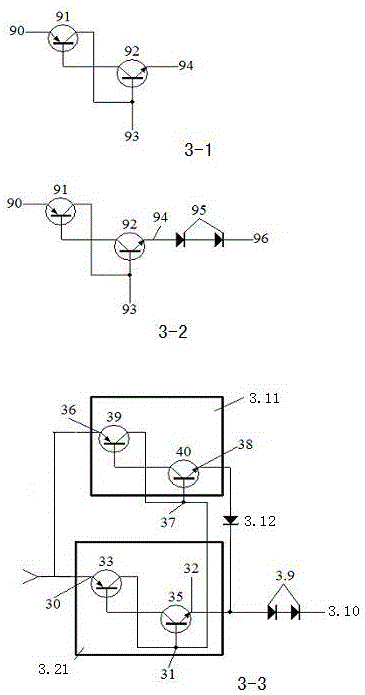

[0093] figure 1 , 2 , 3, 4, 5 examples show a kind of production scheme in the implementation of low-carbon thyristor type environmental protection charger.

[0094] 1. Selection of components: The cathode series diodes that make up the innovative silicon controlled rectifier are composed of two surface-mounted diodes connected in series. All thyristors are welded one-way thyristors. The charging conversion tube is an NPN triode. Diodes are surface-bonded diodes, and there are no special requirements for other resistance-capacitance components.

[0095] 2. Plate making and welding: according to figure 2 Make the circuit control board and press the connection figure 2 Schematic for soldering.

[0096] 3. Power on, check and debug.

[0097] 1. Power-on inspection and debugging of the constant current unit.

[0098] A. If Figure 4 As shown, solder a dummy load instead of the battery being charged. Connect a triode to form an adjustable voltage regulator analog circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com