[0003] At present, the commonly used fermentation method for Pu-erh cooked tea is stacking fermentation, that is, stacking Pu-erh tea on the ground to a certain height, generally 70-100 cm, and adding a certain amount of water for stacking fermentation. The temperature and

water content, judge the time of turning over, replenishing water, and the time of ending fermentation through experience, the whole process is carried out in an open environment, harmful microorganisms in the environment cannot be controlled, and

hygiene cannot be guaranteed, and because it is natural

pile fermentation , the fermentation process will cause high

core temperature, low

peripheral temperature, uneven fermentation, long fermentation cycle, and many uncontrollable factors in the fermentation, resulting in unstable product quality after fermentation and cannot be unified

[0004] In response to the above problems, some manufacturers have established off-the-ground fermentation technology, that is, Pu-erh tea is fermented in a specific space, including fermentation in a fermentation tank, off-the-ground fermentation on wooden boards, and tea-building fermentation in bamboo baskets. There has been some improvement, but the entire fermentation process is still uncontrollable; and, with the improvement of the quality requirements for Pu-erh cooked tea products, further improvement of fermentation technology is required, for example, in a closed environment, the environment is relatively clean, and different microorganisms are added to promote the fermentation process.

Fermentation process, although this fermentation technology strengthens the role of microorganisms to a certain extent, the types of microorganisms are still uncontrollable, and the fermentation process is still a natural

pile, with a long fermentation period. Although a stirring

paddle is added, it replaces artificial Turning over the heap, due to the strong force of the stirring

machine, it is easy to stir and break the tea leaves in the heap. None of the above technologies has substantially improved the fermentation process of Pu-erh cooked tea

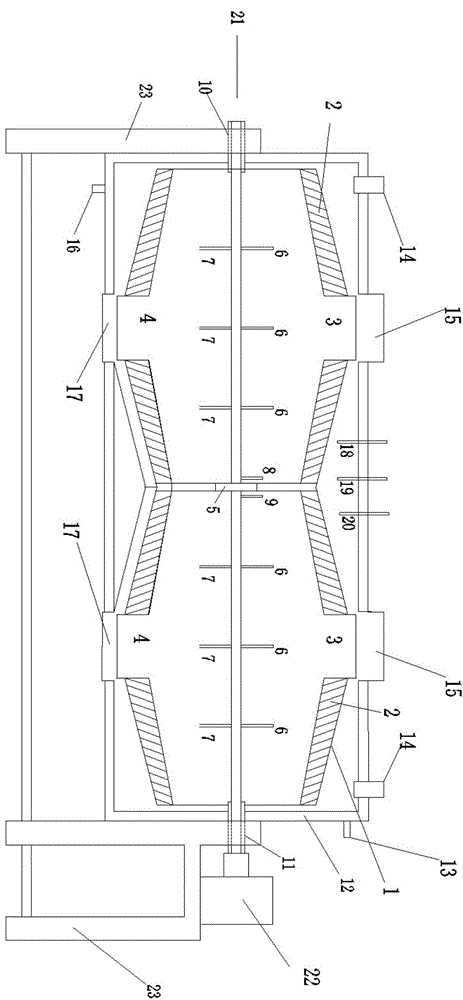

Chinese patent application 200920111698.9 further improved the fermentation technology of Pu'er cooked tea, and designed a double-layer moisturizing and rotating Pu'er tea fermenter. Due to the sealing of the fermenter, it can reduce the volatilization of water during the fermentation process, and make the fermentation more uniform through the rotation of the fermenter. , can maintain the integrity of the tea leaves, but still cannot precisely control the key parameters of the Pu-erh tea fermentation process, such as temperature and humidity;

Chinese patent application 201120201948.5 regulates the temperature by adjusting the steam volume and air intake volume, and the steam is easy to form a local high temperature, Affects the quality of tea;

Chinese patent application 201520087465.5 improves the fermentation tank of Pu’er tea, and adopts the method of rotating the stirring rod to make Pu’er tea disperse more evenly, but still cannot automatically control the temperature and humidity; Chinese

patent application 201520203678. Great improvement has been made. Sampling ports are set at different heights of the fermenter for sampling, observation, and temperature detection. This patent is based on the detection results of the temperature of the sampling port to control the temperature change in the fermenter, which cannot realize online real-time detection and detection.

Water content is also controlled by taking samples to detect the

water content of tea leaves and adjusting the

water supply, which cannot maintain the humidity in the fermentation tank; moreover, it has to rely on multiple sampling operations, which greatly increases the probability of continuous

contamination of

bacteria during the fermentation process and significantly reduces Advantages of making Pu-erh cooked tea in fermenter

More importantly, the most critical thing is the pretreatment of raw Pu-erh cooked tea. This patent uses steam treatment for 5-20 minutes before Pu-erh tea is fermented. Although this method avoids unnecessary

pollution caused by off-site sterilization, it is

Moist heat sterilization will not only significantly change the water content of Pu-erh tea, but also rapidly oxidize its polyphenols, resulting in a great change in quality. The paper "The Effects of Different Sterilization Methods on the Quality and Main Microorganisms of Pu-erh Loose Tea" published by the Center confirmed that, at the same time,

steam sterilization can make Pu-erh cooked tea meet hygienic standards, but it almost kills a large number of molds in raw materials of Pu-erh tea. , while the different embodiments of this patent only inoculate a single

microorganism, such as:

Lactobacillus pentosus,

Bacillus amyloliquefaciens or

Candida parapsilosis. The above are all inoculated with a single

microorganism. According to the existing research results, molds are also achieved The key

microorganism type for the fermentation of Pu’er cooked tea, and this patent is difficult to achieve the fermentation of Pu’er cooked tea when only one kind of microorganism is added

In addition, the patent fermenter is a horizontal cylinder, the bottom is on a plane, and the material is discharged from one end of the bottom, the tea leaves are easy to accumulate at the other end, causing certain difficulties

[0005] At present, the improved Pu-erh tea fermentation method, that is, the use of fermentation tanks, still has the following problems: ①The problem of sterilization of raw materials. There are many types of microorganisms on Pu-erh tea.

Bacteria is a key issue; ②Puer tea fermentation process is mainly the result of the

joint action of various microorganisms and enzymes, and the condition control is complex.

Process control technology is an urgent problem to be solved; ③Puer tea has a long fermentation cycle and

high energy consumption. How to save energy and reduce consumption and improve efficiency needs a breakthrough urgently

Login to View More

Login to View More  Login to View More

Login to View More