High-stability famciclovir tablet and preparation method thereof

A technology of famciclovir and high stability, which is applied in the field of high stability famciclovir tablets and its preparation, can solve the problems of intolerance to storage and high impurities of famciclovir tablets, and achieve the effect of high dissolution rate and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

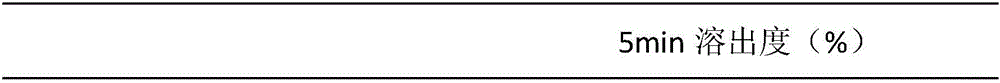

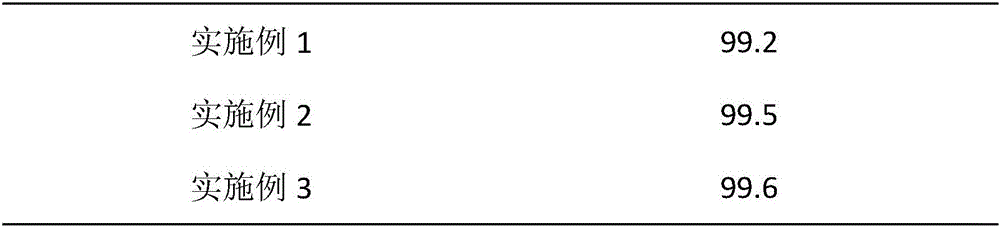

Examples

Embodiment 1

[0021] (1) Famciclovir, mannitol, carboxymethyl starch sodium and sodium bicarbonate are mixed, and the weight ratio of described famciclovir, mannitol, carboxymethyl starch sodium and sodium bicarbonate is 3:1:0.5:0.8;

[0022] (2) Add carmellose ethanol solution of 3.5% by weight to the resultant of step (1) to make soft material, granulate through a 14 mesh sieve, dry at 65-75° C., and then sieve through a 20 mesh sieve grain;

[0023] (3) add magnesium stearate and crospovidone to step (2) gained, the add-on of magnesium stearate is 5% of famciclovir weight, the add-on of crospovidone is 3% of famciclovir weight , carry out tabletting, that is to say.

Embodiment 2

[0025] (1) Famciclovir, mannitol, carboxymethyl starch sodium and sodium bicarbonate are mixed, and the weight ratio of described famciclovir, mannitol, carboxymethyl starch sodium and sodium bicarbonate is 5:1.5:0.6:1;

[0026] (2) Add carmellose ethanol solution of 2.8% by weight to the result of step (1) to make soft material, pass through 14 mesh sieve to granulate, dry at 65-75°C, and then sieve through 20 mesh grain;

[0027] (3) add magnesium stearate and crospovidone to step (2) gained, the add-on of magnesium stearate is 8% of famciclovir weight, the add-on of crospovidone is 5% of famciclovir weight , carry out tabletting, that is to say.

Embodiment 3

[0029] (1) Famciclovir, mannitol, carboxymethyl starch sodium and sodium bicarbonate are mixed, and the weight ratio of described famciclovir, mannitol, carboxymethyl starch sodium and sodium bicarbonate is 4.6:1.3:0.55:0.85;

[0030] (2) Add carmellose ethanol solution of 3% by weight to the result of step (1) to make a soft material, pass through a 14 mesh sieve to granulate, dry at 65-75°C, and then sieve through a 20 mesh sieve grain;

[0031] (3) add magnesium stearate and crospovidone to step (2) gained, the add-on of magnesium stearate is 6% of famciclovir weight, the add-on of crospovidone is 4% of famciclovir weight , carry out tabletting, that is to say.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com